Valve sand casting mold

A technology of sand casting and sand casting, which is applied in the field of sand casting molds for valves. It can solve the problems of poor casting precision, falling sand, and sand inclusions in castings, and achieve the effects of reducing sand inclusions in castings, increasing the yield of castings, and improving the precision of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

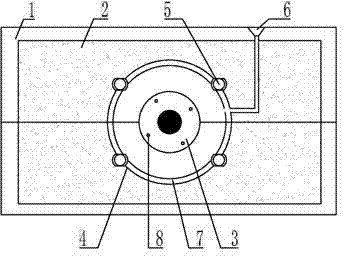

[0015] Such as figure 1 As shown, the valve sand casting mold includes a sand box 1, a sand mold 2, a core and an anti-stick coating 4. It is characterized in that: the core adopts a structure of one main core 3 and four auxiliary cores 5, and there are multiple air holes 8 on the core. . In the valve sand casting mold of the present invention, the sand box 1 is provided with a trumpet-shaped sprue 6 to avoid hidden dangers caused by molten iron splashing. The core adopts a structure of one main core and four auxiliary cores. The main core is used to cast the main body of the valve, and the auxiliary core is used to cast the bolt holes on the valve. The valves thus produced are formed once, without the need for secondary processing to drill bolt holes, which ensures the accuracy and aesthetics of the valves. The main core 3 and the auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com