Heavy oil hydrotreating catalyst and preparation and application

A heavy oil hydrogenation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as downstream catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

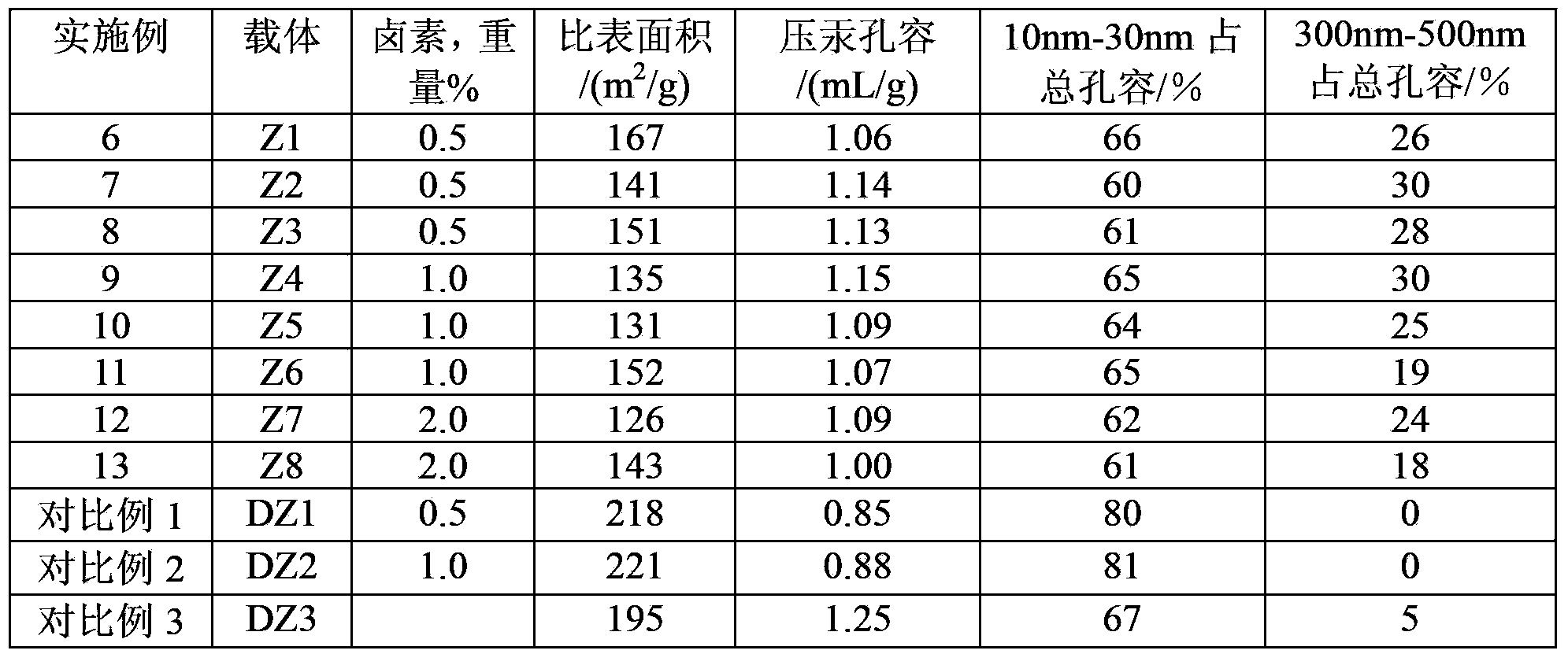

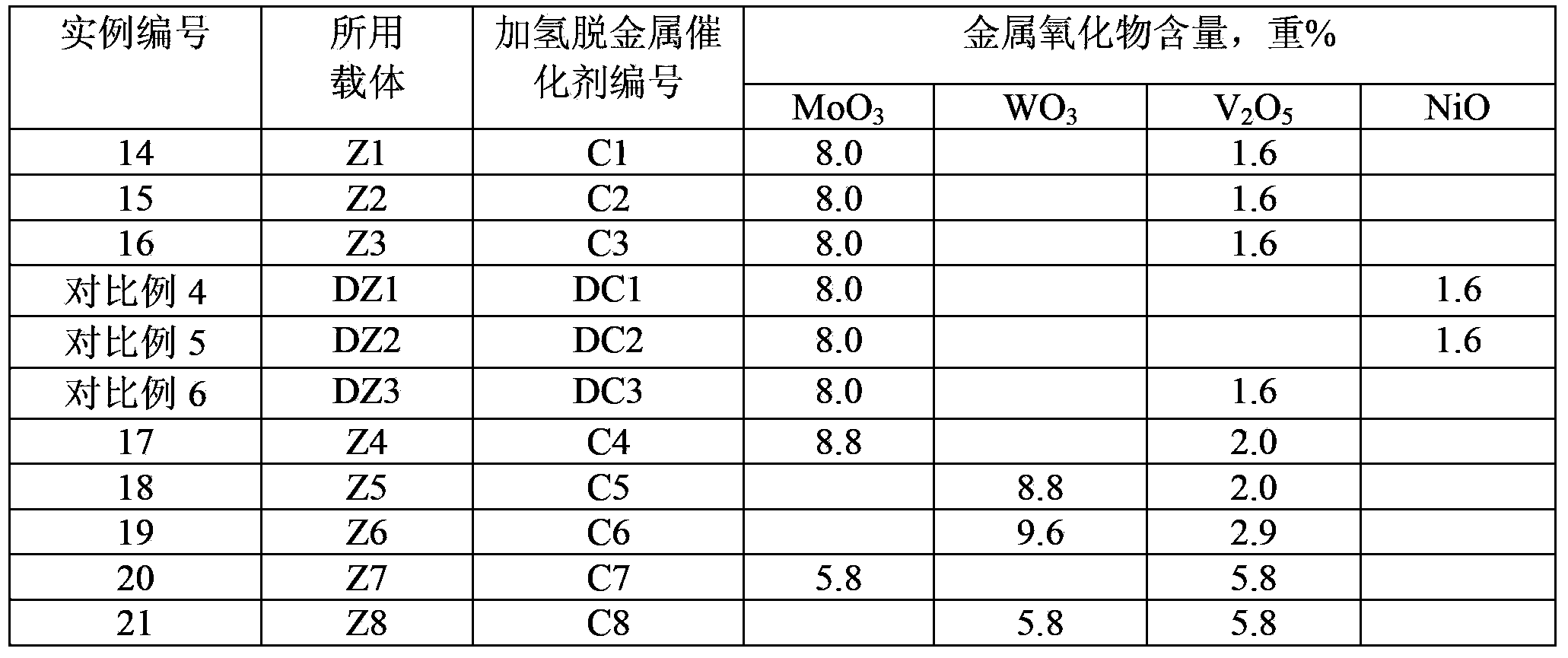

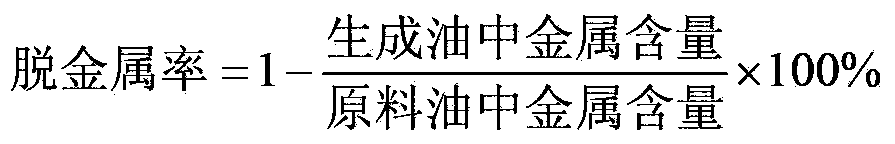

Examples

Embodiment 1

[0061] Weigh 1000 g of P1-1, then add 1440 ml of aqueous solution containing 10 ml of nitric acid (product of Tianjin Chemical Reagent No. Dry the wet strips at 120°C for 4 hours to obtain dry strips, shape the dry strips, sieve, grind and sieve the dry strip materials (generally called industrial dry strip waste) with a length of less than 2mm, and take 100-200 Mesh sieving to obtain the modified product P2A of P1-1. The k values of P2A are shown in Table 1.

Embodiment 2

[0063] Weigh 1000 g of P1-1, and flash dry at 240°C for 6 minutes to obtain P2B, a modified product of P1-1. See Table 1 for the k values of P2B.

Embodiment 3

[0065] 200 grams each of P2A obtained in Example 1 and P2B obtained in Example 2 were evenly mixed to obtain the modified product P2C of P1-1. See Table 1 for the k value of P2C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com