Tebipenem pivoxil granule and preparation method thereof

A technology of tipipenem ester and tipipenem, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as discomfort and improve compliance , improve stability, and easily expand production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

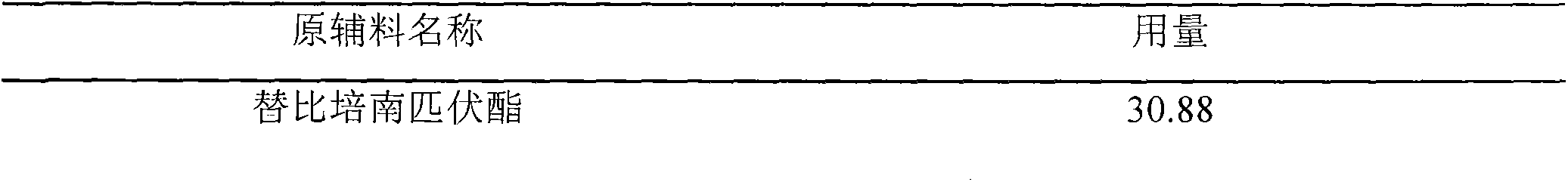

[0019]

[0020]

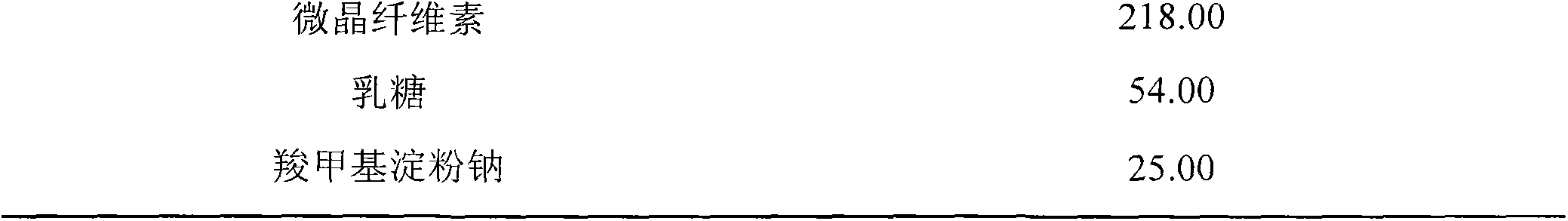

[0021] Composition of resin coating layer:

[0022]

[0023] Composition of the powder coating layer:

[0024]

[0025] Preparation Process:

[0026] (1) Ball core preparation:

[0027] a. Take tipipenem ester, microcrystalline cellulose, lactose, and carboxymethyl starch sodium and pass through a 60-mesh sieve respectively, and set aside;

[0028] b. Take the tipipenem ester, microcrystalline cellulose, lactose, and sodium carboxymethyl starch in the prescribed amount, mix them evenly, and set aside;

[0029] c. Mix powder and add water to make soft materials, and put them in an extrusion spheronizer to granulate;

[0030] d. Fluidized bed drying, drying temperature 50 ℃;

[0031] (2) Resin layer coating:

[0032] a. Take purified water, stir and add the coating material of Youteqi series, talcum powder, sodium lauryl sulfate and stir evenly;

[0033] b. Turn on the fluidized bed, add granules to preheat, and carry out coating. The coating ...

Embodiment 2

[0038]

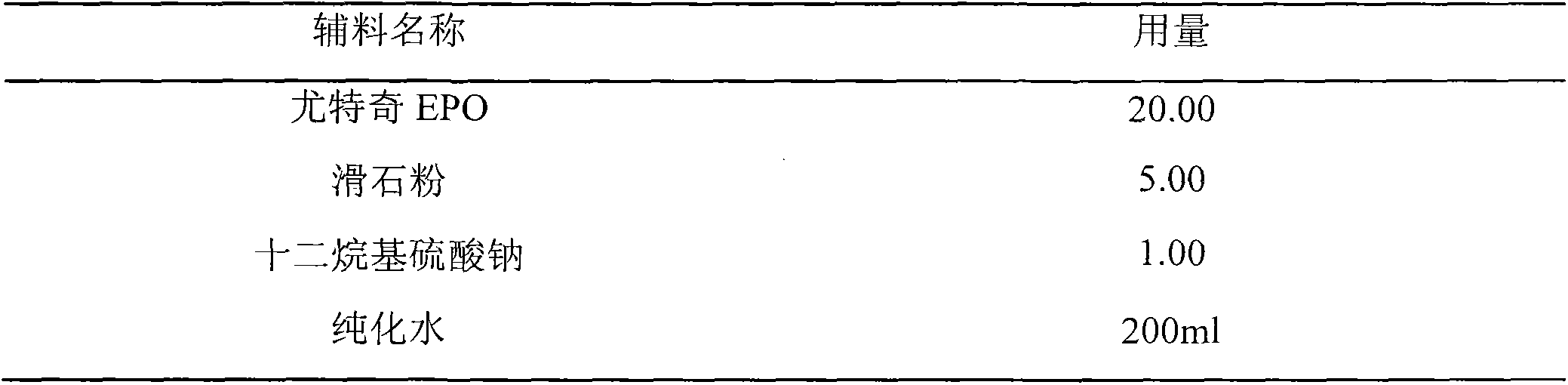

[0039] Composition of resin coating layer:

[0040]

[0041] Composition of the powder coating layer:

[0042]

[0043] Preparation Process:

[0044] (1) Ball core preparation:

[0045] a. Take tipipenem ester, microcrystalline cellulose, lactose, and sodium carboxymethyl starch and pass through an 80-mesh sieve respectively, and set aside;

[0046] b. Take the tipipenem ester, microcrystalline cellulose, lactose, and sodium carboxymethyl starch in the prescribed amount, mix them evenly, and set aside;

[0047] c. Mix the powder and add water to make a soft material, and put it in an extrusion spheronizer to granulate;

[0048] d. Fluidized bed drying, drying temperature 60 ℃;

[0049] (2) Resin layer coating:

[0050] a. Take purified water, stir and add the coating material of Youteqi series, talcum powder, sodium lauryl sulfate and stir evenly;

[0051] b. Turn on the fluidized bed, add granules to preheat, and carry out coating. The coating temperat...

Embodiment 3

[0056]

[0057] Composition of resin coating layer:

[0058]

[0059] Composition of the powder coating layer:

[0060]

[0061] Preparation Process:

[0062] (1) Ball core preparation:

[0063] a. Take tipipenem ester, microcrystalline cellulose, lactose, and carboxymethyl starch sodium and pass through a 100-mesh sieve respectively, and set aside;

[0064] b. Take the tipipenem ester, microcrystalline cellulose, lactose, and sodium carboxymethyl starch in the prescribed amount, mix them evenly, and set aside;

[0065] c. Mix the powder and add water to make a soft material, and put it in an extrusion spheronizer to granulate;

[0066] d. Fluidized bed drying, drying temperature 50 ℃;

[0067] (2) Resin layer coating:

[0068] a. Take purified water, stir and add the coating material of Youteqi series, talcum powder, sodium lauryl sulfate and stir evenly;

[0069] b. Turn on the fluidized bed, add granules to preheat, and carry out coating. The coating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com