Preparation method of whole apple powder

A technology of apples and apple slices, which is applied in the field of food processing, can solve problems such as difficulty in meeting market demand and limitations in the production process of apple powder products, and achieve the effects of high added value, easy absorption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] A preparation method of apple whole powder, the steps are as follows:

[0011] 1) Using fresh apples as raw materials, first rinse the apples with clean water, then soak them in a citric acid solution with a concentration of 1% to 1.2% for 5 to 10 minutes, then rinse them with clean water, rinse them and drain them for later use;

[0012] 2) Remove the core and inedible parts of the fruit pedicle, cut the apples into 3-7mm thick apple slices, soak them in the color protection solution for 25-35 minutes, and drain;

[0013] 3) Put the apple slices after color protection in step 2) into a hot air drying oven for pre-drying to a moisture content of 35-45 wt%, then pre-expand the pre-dried apple slices to a moisture content of 15-25 wt%, and then microwave The puffed apple slices are subjected to low-temperature air-flow puffing treatment until the moisture content is below 6wt%, so as to obtain apple crisps;

[0014] 4) Superfinely pulverize, sieve and package the apple c...

specific Embodiment approach

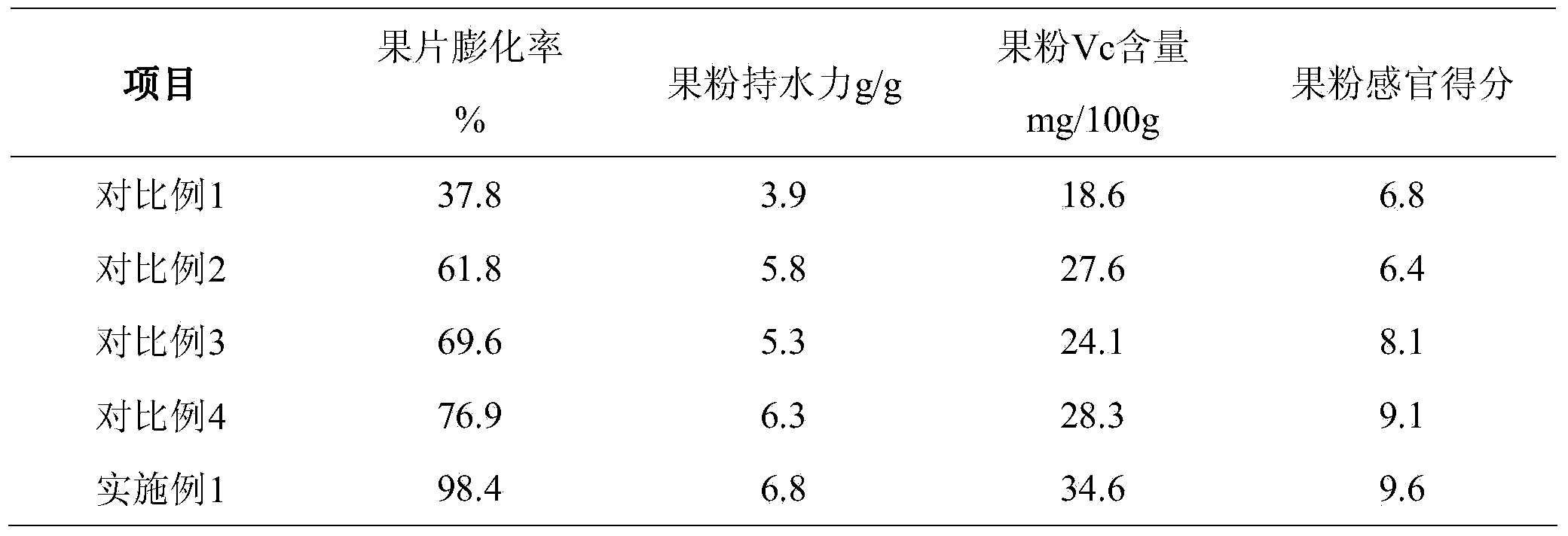

[0030] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0031] The apple raw material used in the embodiment is produced in Qixia, Yantai City;

[0032] The electric blast drying oven was purchased from Tianjin Test Instrument Co., Ltd., model: 101-3A;

[0033]The microwave dryer was purchased from Jinan Longtai Microwave Equipment Co., Ltd., model: LT-4S;

[0034] The low-temperature airflow fruit and vegetable puffing dryer was purchased from Tianjin Qinde New Material Technology Co., Ltd., model: QDPH1000-4;

[0035] The ultrafine pulverizer was purchased from Jinan Beili Powder Technology Co., Ltd., model: BFM-6

[0036] The whole apple powder prepared in the embodiment of the present invention is used as a food ingredient in various food fields.

Embodiment 1

[0038] A preparation method of apple whole powder, the steps are as follows:

[0039] 1) Select 10 kg of the remaining extra-grade fruit for canning, first rinse the apples with clear water, then soak them in a citric acid solution with a concentration of 1 wt% for 5 minutes, then rinse them with clear water, rinse them and drain them for later use;

[0040] 2) Remove the core and inedible parts of the fruit pedicle, cut the apples into 5mm thick apple slices, soak in the color protection solution for 30 minutes, and drain; the color protection solution contains ascorbic acid, citric acid, EDTA-2Na, sodium chloride aqueous solution, wherein the mass concentration of ascorbic acid is 0.7%, the mass concentration of citric acid is 0.9%, the mass concentration of EDTA-2Na is 0.1%, and the mass concentration of sodium chloride is 0.5%;

[0041] 3) Put the apple slices after step 2) into a hot air drying oven to pre-dry to a water content of 41.7%. After the apple slices were micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com