Gearbox and turbine engine with geared fan

A gearbox and planetary gear technology, applied in gear transmissions, engine components, machines/engines, etc., can solve problems such as increased complexity of gearboxes, shortened system-level life, and lack of axial flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

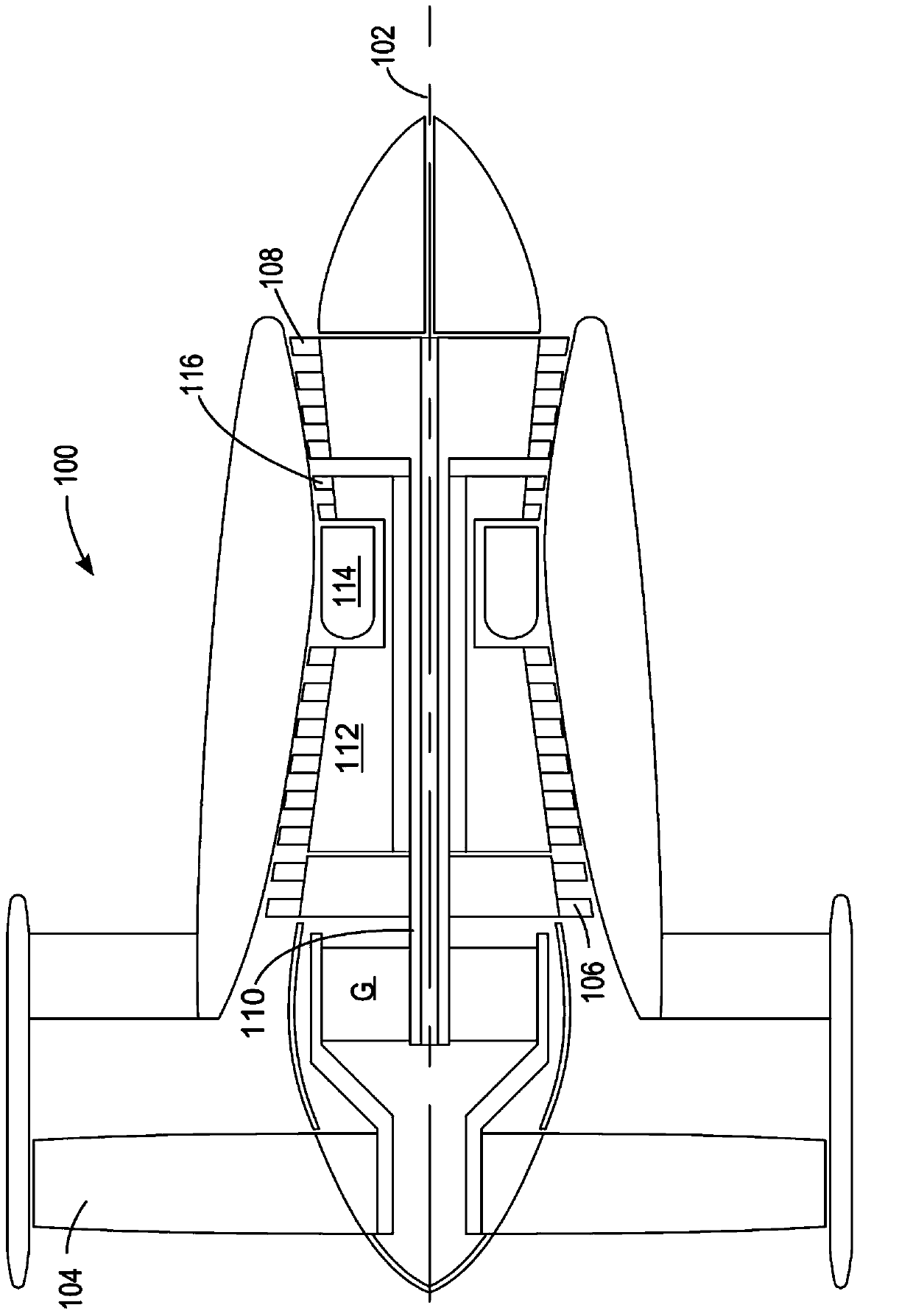

[0020] Referring to the drawings, wherein like reference numerals represent like elements throughout the various drawings, figure 1 An exemplary gas turbine engine 100 constructed in accordance with an aspect of the present invention is shown. Engine 100 has a longitudinal axis 102 and includes a fan 104, a low pressure compressor or "supercharger" 106, and a low pressure turbine ("LPT") 108, collectively referred to as the "low pressure system". The LPT 108 drives the supercharger 106 via an internal shaft 110 , also referred to as the "LP shaft."

[0021] The inner shaft 110 is also connected to a reduction gearbox, generally designated "G," which in turn is connected to the fan 104 . In the illustrated embodiment, the fan 104 is located in front of the LPT 108 and the gearbox G is located behind the fan 104 . However, gearbox G may be located in front of or behind LPT 108 , and fan 104 may be located in front of or behind LPT 108 . The fan 104 may be surrounded by ductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com