Pulse power supply for converting discharge by utilizing three-winding pulse transformer

A pulse transformer and pulse power technology, which is applied in the field of large current generating devices, can solve the problems of reducing system energy transfer efficiency, limited copper winding current-carrying capacity, and increasing device volume and weight, so as to improve energy conversion efficiency, reduce volume and Effect of short weight and switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

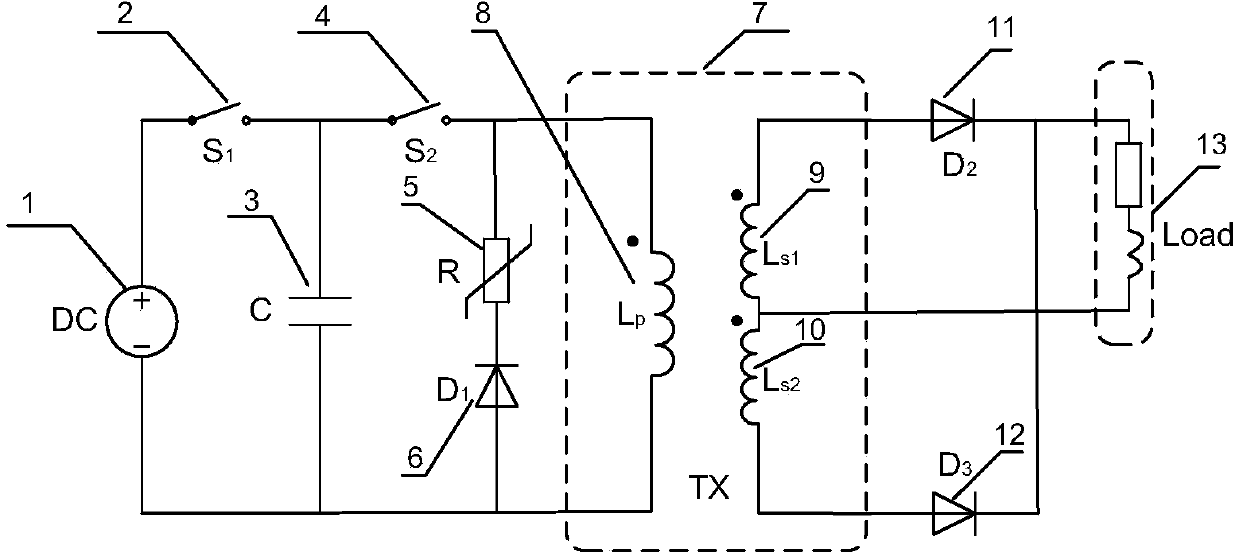

[0016] figure 1 It is a pulse power supply for three-winding conversion and discharge, including 1. High-voltage DC power supply DC, 2. Charge-side switch S1, 3. Energy storage capacitor C, 4. Discharge-side switch S2, 5. Non-linear resistor R, 6. Freewheeling Diode D1, 7. Three-winding pulse transformer TX, 8. Primary winding Lp, 9. Secondary winding Ls1, 10. Secondary winding Ls2, 11. Rectifier diode D2, 12. Rectifier diode D3, 13. Load.

[0017] figure 1 The middle switches S1 and S2 are controllable switches, which can be fully controlled semiconductor switches such as IGBT, IGCT, MOSFET, IECT, GTO, etc., or semi-controlled switches such as SCR with auxiliary turn-off function; the non-linear resistor R can be selected from ZnO or For SiC varistors, products with large nonlinear coefficient, large flow capacity and low residual voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com