PSM high-voltage power supply control system based on MCU and FPGA

A high-voltage power supply and control system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem that the controller is difficult to take into account at the same time, improve the difficulty of control system design and manufacture, and the time domain span is large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

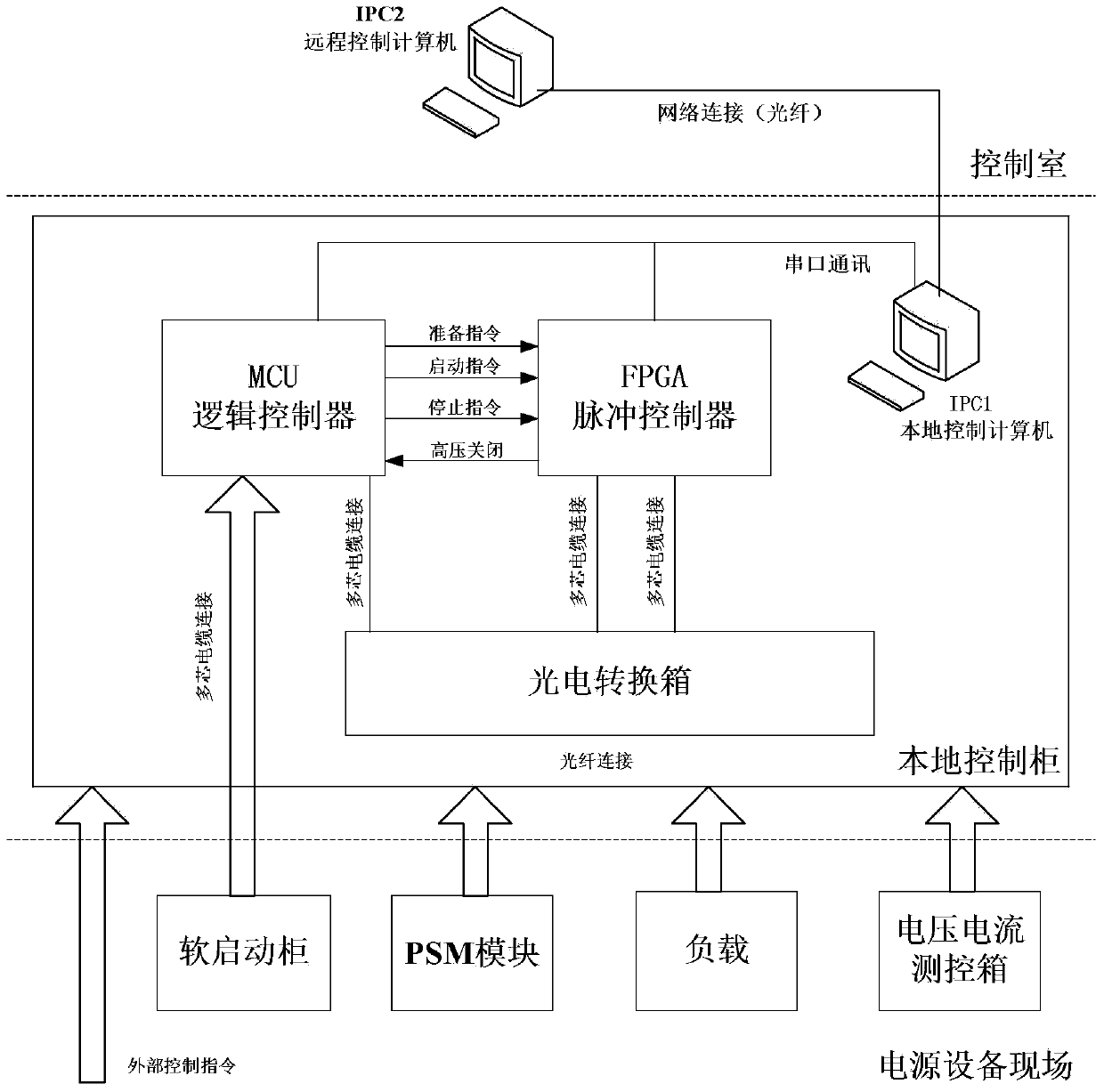

[0034] Such as figure 1 As shown, a PSM high-voltage power supply control system based on MCU and FPGA includes an MCU logic controller and an FPGA pulse controller located in a local control cabinet, and a host computer connected to the MCU logic controller and FPGA pulse controller system and high-voltage power supply field equipment;

[0035]Described upper computer system comprises local control computer IPC1 and remote control computer IPC2 and the control software of matching; Described MCU logic controller and FPGA pulse controller and local control computer IPC1 adopt RS232 serial port communication, local control computer IPC1 and control The remote control computer IPC2 in the room communicates through the network;

[0036] Described high-voltage power field equipment comprises PSM module, voltage and current measurement and control equipment and soft-start contactor cabinet; Described MCU logic controller and FPGA pulse controller are connected to photoelectric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com