An adjustable gravity heat pipe heat transfer efficiency test device

A gravity heat pipe and testing device technology, applied in the direction of material thermal development, etc., can solve the problem that there is no simple and easy method for effective testing of the heat transfer efficiency of gravity heat pipe, and achieve the effect of low working environment requirements, stable work, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

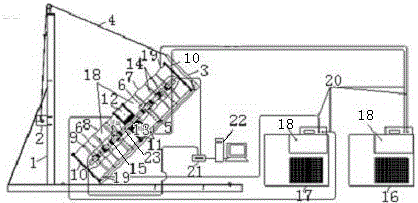

[0018] Below in conjunction with accompanying drawing, the present invention is described further:

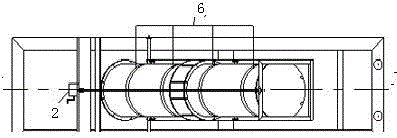

[0019] Such as Figure 1~2 As shown, an adjustable gravity heat pipe heat transfer efficiency test device is composed of a bracket 1, a hand winch with a brake 2, a lifting frame 3, a steel strand 4, an inclinometer 5, a clamping position 6, and an upper temperature control barrel 7. Lower temperature control barrel 8, triangular bracket 9, sealing flange 10, connecting flange 11, guide rod 12, sealing sleeve 13, temperature sensor 14, heat flow sensor 15, 1# cold bath 16, 2# cold bath 17, The cold bath interface 19, the catheter 20, the data collector 21 and the computer 22 are composed. The lifting frame 3 is hinged with the bracket 1 and can rotate freely. There are four clamping positions 6 on it, which are used to fix the upper temperature control barrel 7 and the lower temperature control barrel 8. The upper temperature control barrel 7 and the lower temperature control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com