Super large vertical combined bearing device

A combined bearing and extra-large technology, which is applied in the field of gates, can solve the problems of being unable to bear large radial loads and axial loads at the same time, so as to improve the axial load bearing capacity, weaken the axial load, and improve the axial load capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

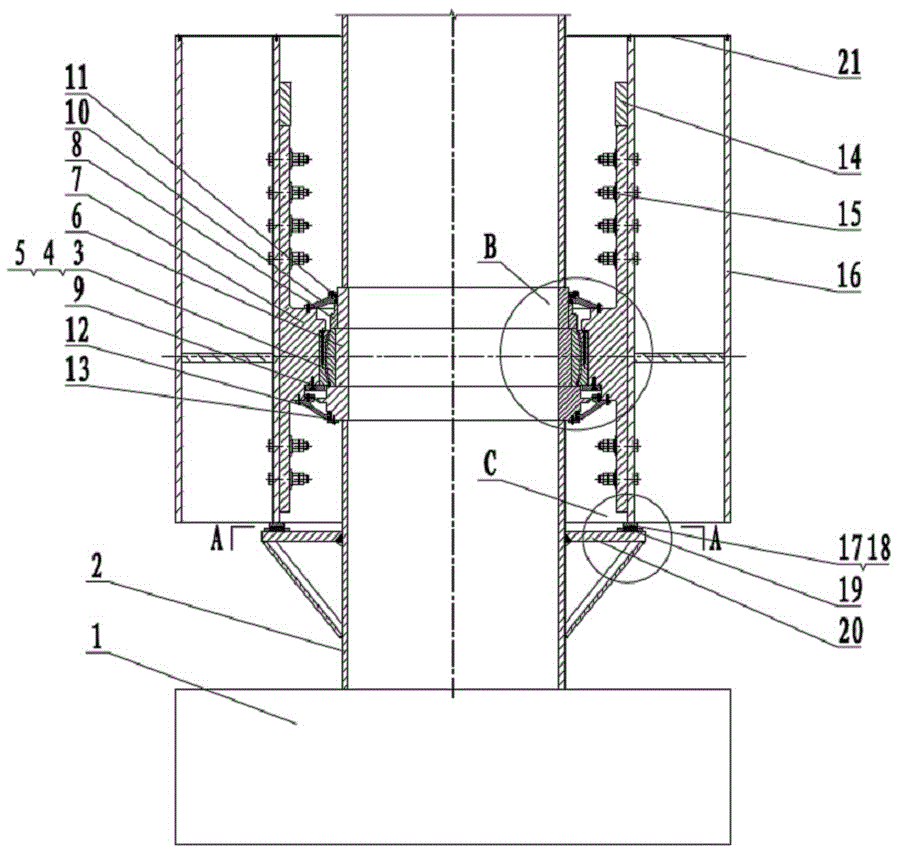

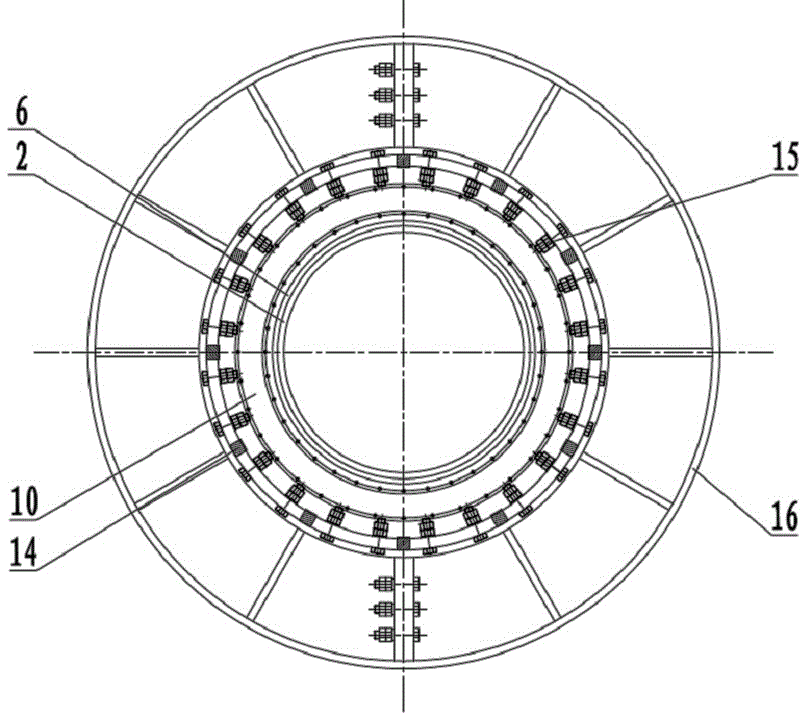

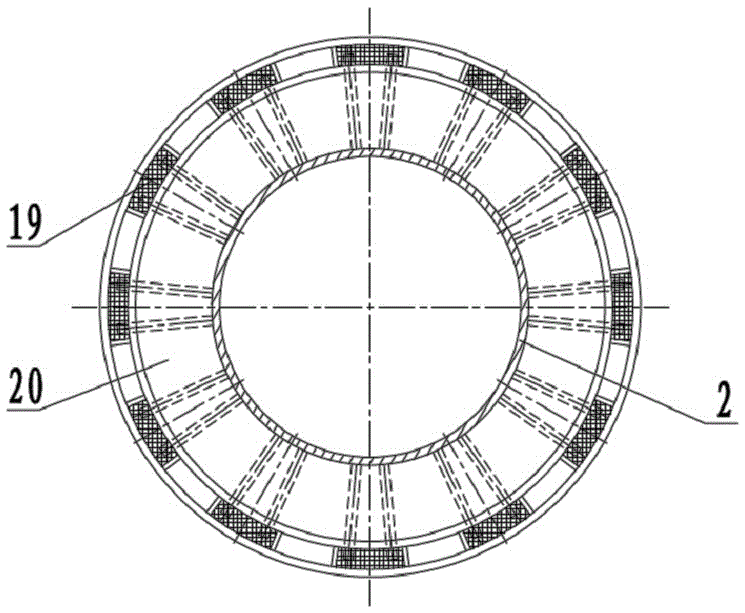

[0030] see figure 1 and figure 2 , The extra-large vertical combined bearing device includes an upright steel pipe column 2 with an outer diameter of 2 meters and a combined bearing. The middle part of the steel pipe column 2 is coaxially welded with a stepped tubular bearing seat 6, and the outer cylindrical surface of the bearing seat 6 is respectively provided with an upper step, a middle step and a lower step, forming a three-stage stepped tube; shaped bearing plate 9; the lower part of the steel pipe column 2 is welded with an annular support platform 20, and the lower end of the steel pipe column 2 is fixedly installed in the concrete foundation 1.

[0031] Combined bearings include center bearings and plane bearings.

[0032] see Figure 4 , The central bearing includes an inner ring 3, an intermediate composite layer 4 and an outer ring 5, the inner diameter of the central bearing is 2120mm, and it is set in the middle of the bearing housing 6. The specific detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com