Rotary excavating pile machine double-cylinder hydraulic grab

A technology of hydraulic grab bucket and rotary pile driver, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. , the directionality is difficult to control accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

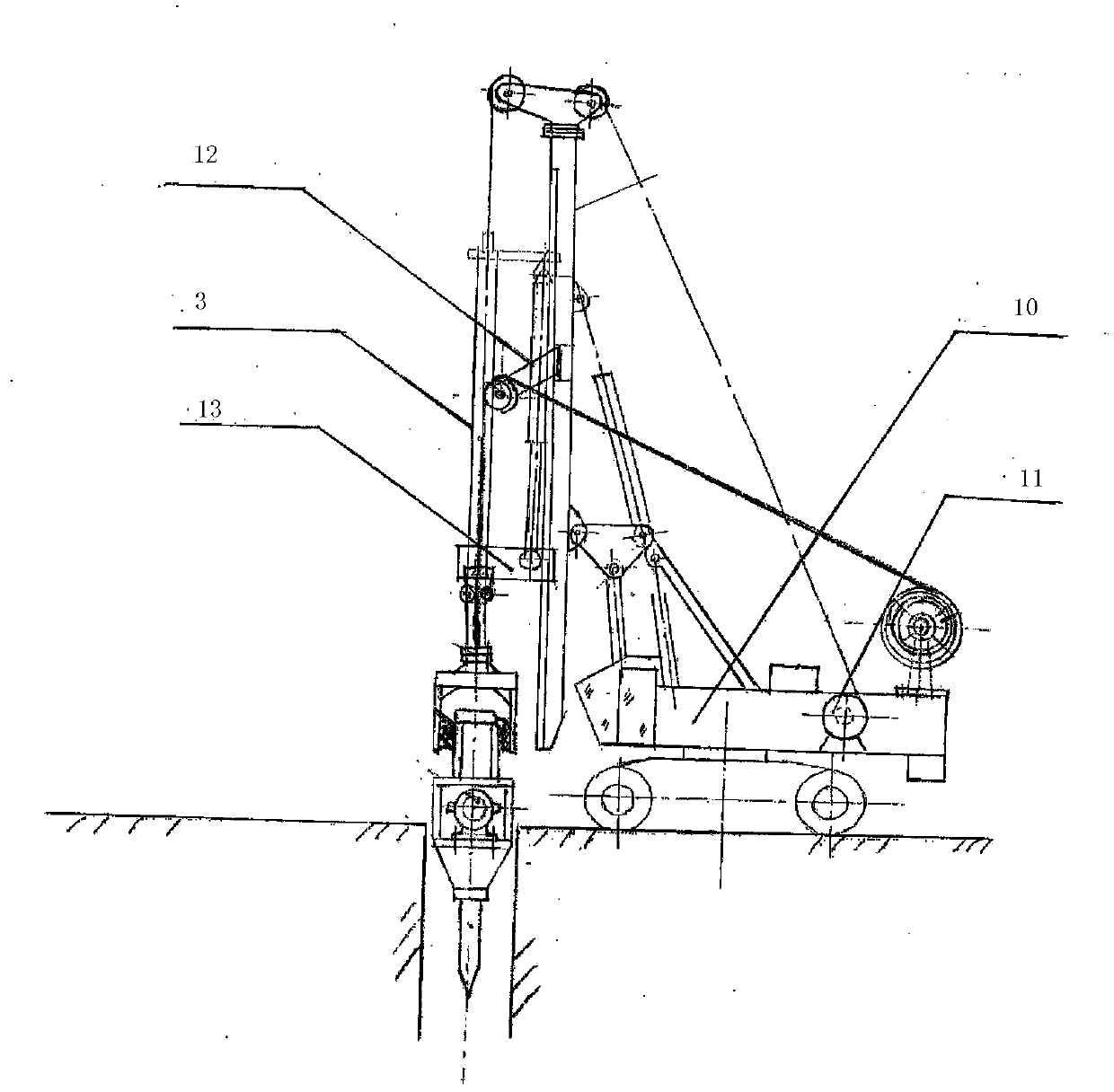

[0011] Such as figure 1 As shown, the hydraulic grab of the present invention mainly includes the opening and closing hydraulic cylinder 4, the jaw clutch 5, the upper and lower vertical tubes 2, 6, the grab bucket 7 and the synchronizer 8, and the upper and lower vertical tubes 2, 6 are a hollow The upper and lower cylinders 2 and 6 are connected by flanges, and the upper end of the lower cylinder 6 is provided with a jaw clutch 5, and the upper end of the jaw clutch 5 is fixed on the lower plane of the flange of the lower cylinder 6. The lower ends of the upper and lower vertical tubes 6 are respectively connected to two grab buckets 7; a synchronizer 8 is connected between the two grab buckets 7 through a connecting pin; Ears with holes, one end of the two opening and closing hydraulic cylinders 4 are symmetrically connected to the two ears of the upper vertical cylinder 2; the other ends of the two opening and closing hydraulic cylinders 4 are telescopic ends, which are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com