A novel antibacterial and fragrant quilt fabric and its preparation method

A fragrance and fabric technology, applied in the field of fabrics and textile fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

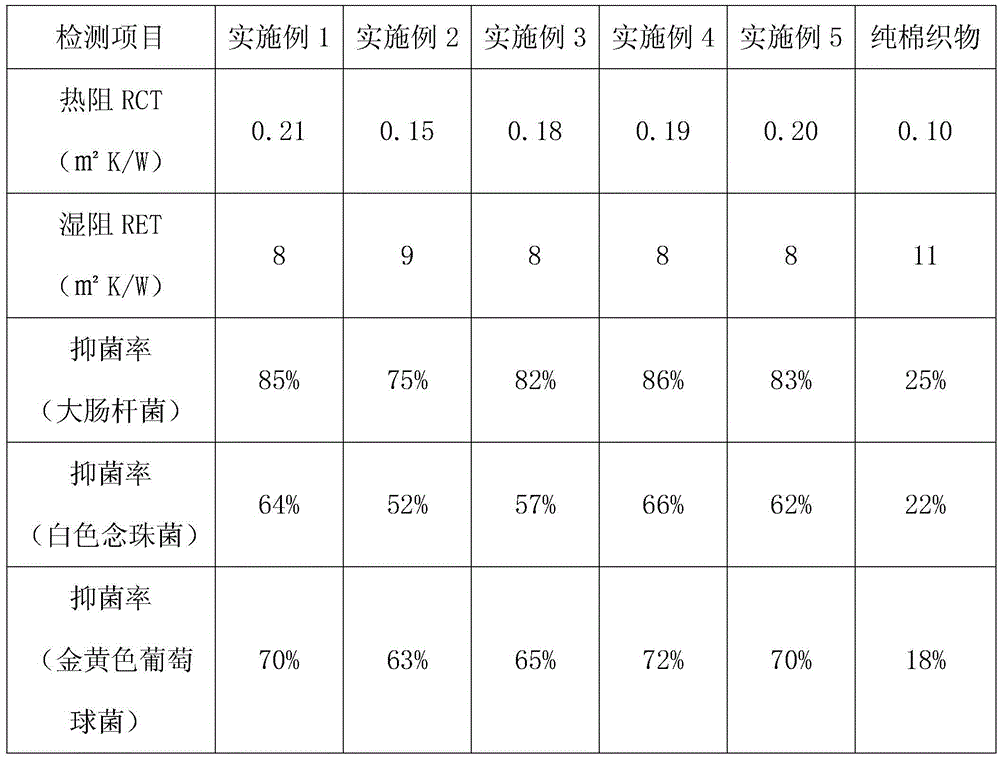

Examples

Embodiment 1

[0026] 1. A new type of antibacterial and aromatic quilt fabric, characterized in that the warp direction is woven with blended yarns of polyester high-fiber and cupro fiber, and the weft direction is made of polyester high-fiber, bamboo fiber and cupro fiber. The yarn is woven; the weight percentage of polyester high f filament in the warp direction blended yarn is 80%, and the weight percent of cupro ammonia fiber is 20%; the weight percent of polyester high f filament in the weft direction blended yarn is 45% %, the weight percentage of bamboo fiber is 40%, and the weight percentage of cupro fiber is 15%.

[0027] 2. A method for preparing a novel antibacterial and aromatic quilt fabric, comprising the following steps:

[0028] A. Opening pretreatment: Carding polyester high-fiber, bamboo fiber and cupro ammonia fiber into fiber sliver on the carding machine;

[0029] B. Spinning and weaving: Combine the fibers weighed in proportion on the drawing frame to make mature sliv...

Embodiment 2

[0036] 1. A new type of antibacterial and aromatic quilt fabric, characterized in that the warp direction is woven with blended yarns of polyester high-fiber and cupro fiber, and the weft direction is made of polyester high-fiber, bamboo fiber and cupro fiber. The yarn is woven; the weight percentage of polyester high f filament in the warp direction blended yarn is 75%, and the weight percent of cupro ammonia fiber is 25%; the weight percent of polyester high f filament in the weft direction blended yarn is 55% %, the weight percentage of bamboo fiber is 30%, and the weight percentage of cupro fiber is 15%.

[0037] 2. A method for preparing a novel antibacterial and aromatic quilt fabric, comprising the following steps:

[0038] A. Opening pretreatment: Carding polyester high-fiber, bamboo fiber and cupro ammonia fiber into fiber sliver on the carding machine;

[0039]B. Spinning and weaving: Combine the fibers weighed in proportion on the drawing frame to make mature slive...

Embodiment 3

[0046] 1. A new type of antibacterial and aromatic quilt fabric, characterized in that the warp direction is woven with blended yarns of polyester high-fiber and cupro fiber, and the weft direction is made of polyester high-fiber, bamboo fiber and cupro fiber. The yarn is woven; the weight percentage of polyester high-fiber in the warp direction blended yarn is 75%, and the weight percentage of cupro ammonia fiber is 25%; the weight percentage of polyester high-fiber in the weft direction blended yarn is 50% %, the weight percentage of bamboo fiber is 35%, and the weight percentage of cupro ammonia fiber is 15%.

[0047] 2. A method for preparing a novel antibacterial and aromatic quilt fabric, comprising the following steps:

[0048] A. Opening pretreatment: Carding polyester high-fiber, bamboo fiber and cupro ammonia fiber into fiber sliver on the carding machine;

[0049] B. Spinning and weaving: Combine the fibers weighed in proportion on the drawing frame to make mature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com