Method of extracting shiny-leaf yellowhorn oil from shiny-leaved yellowhorn seeds

A technology of sorbifolia oil and fruit seeds, which is applied in the direction of fat oil/fat production and fat generation, and can solve the problems of extracting sorbifolia oil that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

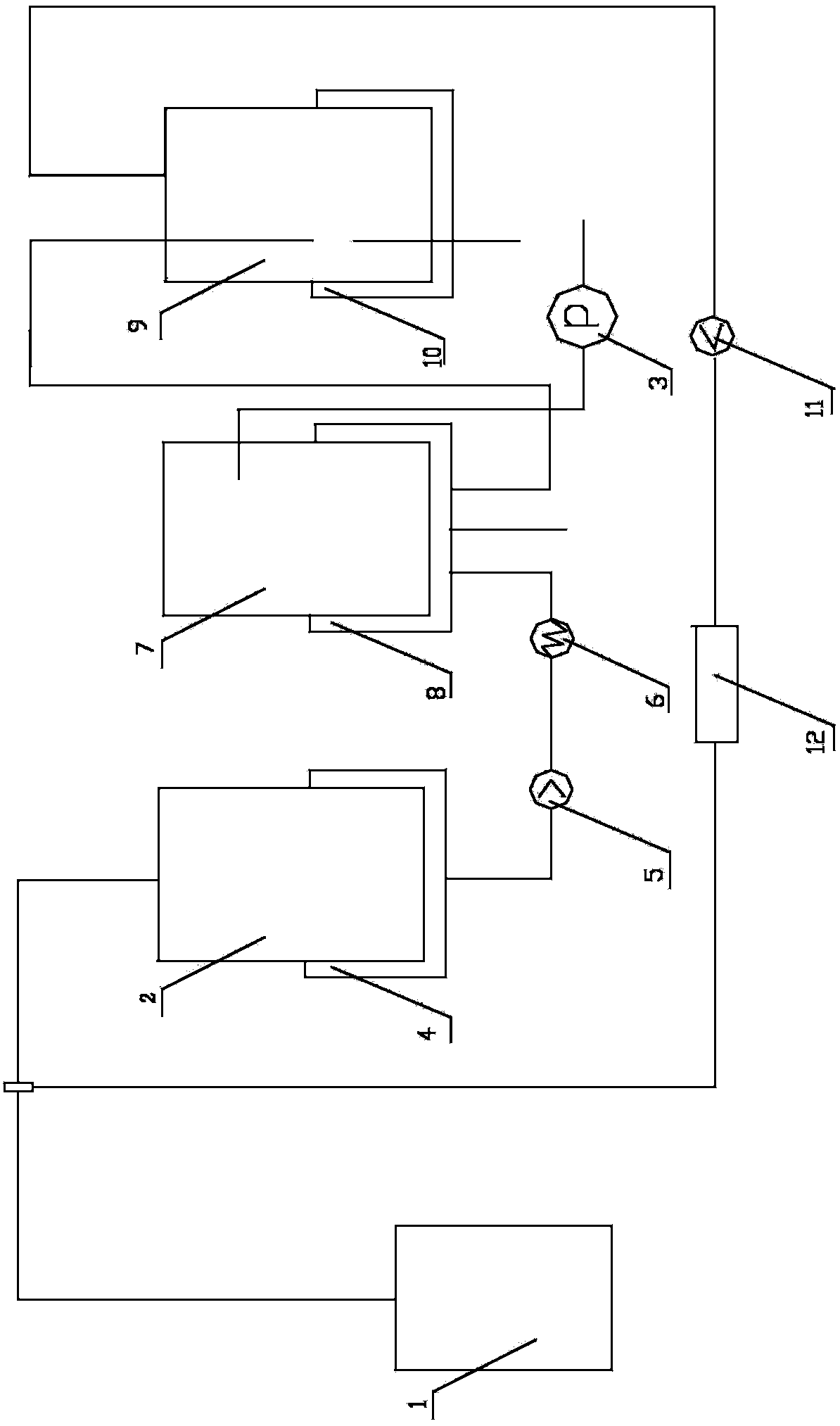

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of method extracting sorbifolia oil from sorbifolia seed, its main feature is to comprise the steps:

[0022] (1) Screening, cleaning, and drying the raw materials of sorbifolia seeds until the water content is ≤13%, the drying temperature is 60° C., and the drying time is 60 minutes; then, it is crushed to 40 mesh by a pulverizer;

[0023] (2) Put the dried and pulverized Xantho sorbifolium seeds into the extraction kettle, and vacuum down to 1×10 4 Below Pa, discharge the air in the extraction kettle; then use a plunger pump to introduce tetrafluoroethane solution into the extraction kettle, control the extraction temperature to 30°C, the extraction pressure to 1.0Mpa, each extraction time is 40min, and repeat the extraction 3 times; Then separate, the separation temperature is 45 °C, and the negative pressure is gradually reduced to 5×10 with a diaphragm compressor. -2 Pa, each separation time is 30min, and the separation is repeated 3 times to ...

Embodiment 2

[0027] Embodiment 2: a kind of method extracting sorbifolia oil from sorbifolia seed, its main feature is to comprise the steps:

[0028] (1) Screening, cleaning, and drying the raw material of sorbifolia seed until the water content is ≤13%, the drying temperature is 70°C, and the drying time is 50 minutes; then it is crushed to 50 mesh by a pulverizer;

[0029] (2) Put the dried and pulverized Xantho sorbifolium seeds into the extraction kettle, and vacuum down to 1×10 4 Below Pa, discharge the air in the extraction kettle; then use a plunger pump to introduce tetrafluoroethane solution into the extraction kettle, control the extraction temperature to 35°C, the extraction pressure to 1.1Mpa, each extraction time is 35min, and repeat the extraction 3 times; Then separate, the separation temperature is 50°C, and the negative pressure is gradually reduced to 5×10 with a diaphragm compressor. -2 Pa, each separation time is 25min, and the separation is repeated 3 times to obtain...

Embodiment 3

[0033] Embodiment 3: a kind of method extracting sorbifolia oil from sorbifolia seed, its main feature is to comprise the steps:

[0034] (1) Screening, cleaning, and drying the raw materials of sorbifolia seeds until the moisture content is ≤13%, the drying temperature is 80°C, and the drying time is 40 minutes; then, it is crushed to 60 mesh by a pulverizer;

[0035] (2) Put the dried and pulverized Xantho sorbifolium seeds into the extraction kettle, and vacuum down to 1×10 4Below Pa, discharge the air in the extraction kettle; then use a plunger pump to introduce tetrafluoroethane solution into the extraction kettle, control the extraction temperature to 40°C, the extraction pressure to 1.2Mpa, each extraction time is 30min, and repeat the extraction 3 times; Then separate, the separation temperature is 55°C, and the negative pressure is gradually reduced to 5×10 with a diaphragm compressor. -2 Pa, each separation time is 20min, and the separation is repeated 3 times to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com