Pyrithionc zinc ultrafine grain for aqueous coating sterilization and mildew prevention, and its preparation method

A technology of zinc pyrithione and ultrafine particles, which can be used in antifouling/underwater coatings and biocide-containing paints, etc. It can solve the problems of easy agglomeration and poor dispersion, and achieve good uniformity and easy separation and dispersion, easy dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

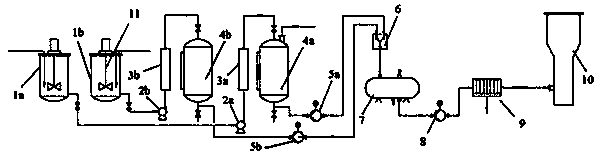

[0040] The preparation method of the ultrafine particles of pyrithione zinc for sterilization and mildew prevention of water-based paints involved in this embodiment is based on figure 1 Shown reaction device structure, it may further comprise the steps:

[0041] 1. Prepare a certain concentration of zinc sulfate solution and sodium pyrithione solution in two reaction liquid preparation tanks, and then enter their respective solution storage tanks through purifiers;

[0042] 2. Add a certain quality of acrylic polymer surfactant into the zinc sulfate solution storage tank, and mix it statically for 20 minutes to 60 minutes;

[0043] 3. The zinc sulfate solution and the sodium pyrithione solution are pressurized by the metering pump respectively and then enter the feed port of the reactor, where they collide with each other at a certain flow rate and precipitate at a high speed in the reactor channel;

[0044] 4. The reaction product is filtered and washed by the plate and fra...

Embodiment 2

[0046] The ultrafine particles of zinc pyrithione used for sterilization and mildew prevention of water-based paints involved in this example adopt the preparation method described in Example 1, and the difference is the reaction parameters, as shown in the following table:

[0047]

[0048] Evaluate the zinc pyrithione wet solid product obtained in the above examples 2.1 to 2.3, evaluate the dispersion of the product by adding the product to the water-based acrylic paint, evaluate the particle size distribution of the product by a Malvern laser particle size analyzer, and scan The average particle size and particle appearance of the product were evaluated by electron microscope, and the results are as follows:

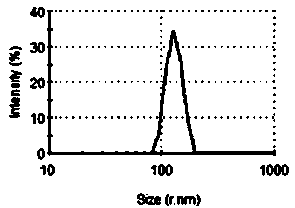

[0049] The wet solid product of zinc pyrithione obtained in embodiment 2.1 can be uniformly dispersed in water-based acrylic paint, such as figure 2 The product granules shown have a narrow particle size distribution, such as image 3 The product shown has unifor...

Embodiment 3

[0053] The following examples relate to the preparation of zinc pyrithione particles using different processes using the same raw material concentration, proportioning ratio and reaction parameters as in Example 2.2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com