Novel chemical oil remover

A new type of chemical degreasing technology, applied in grease/oily substance/float removal devices, liquid separation, flocculation/sedimentation water/sewage treatment, etc., which can solve the problems of short residence time, high surface load and high agitation. , to achieve the effect of reducing the effluent flow rate, reducing agitation, and increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

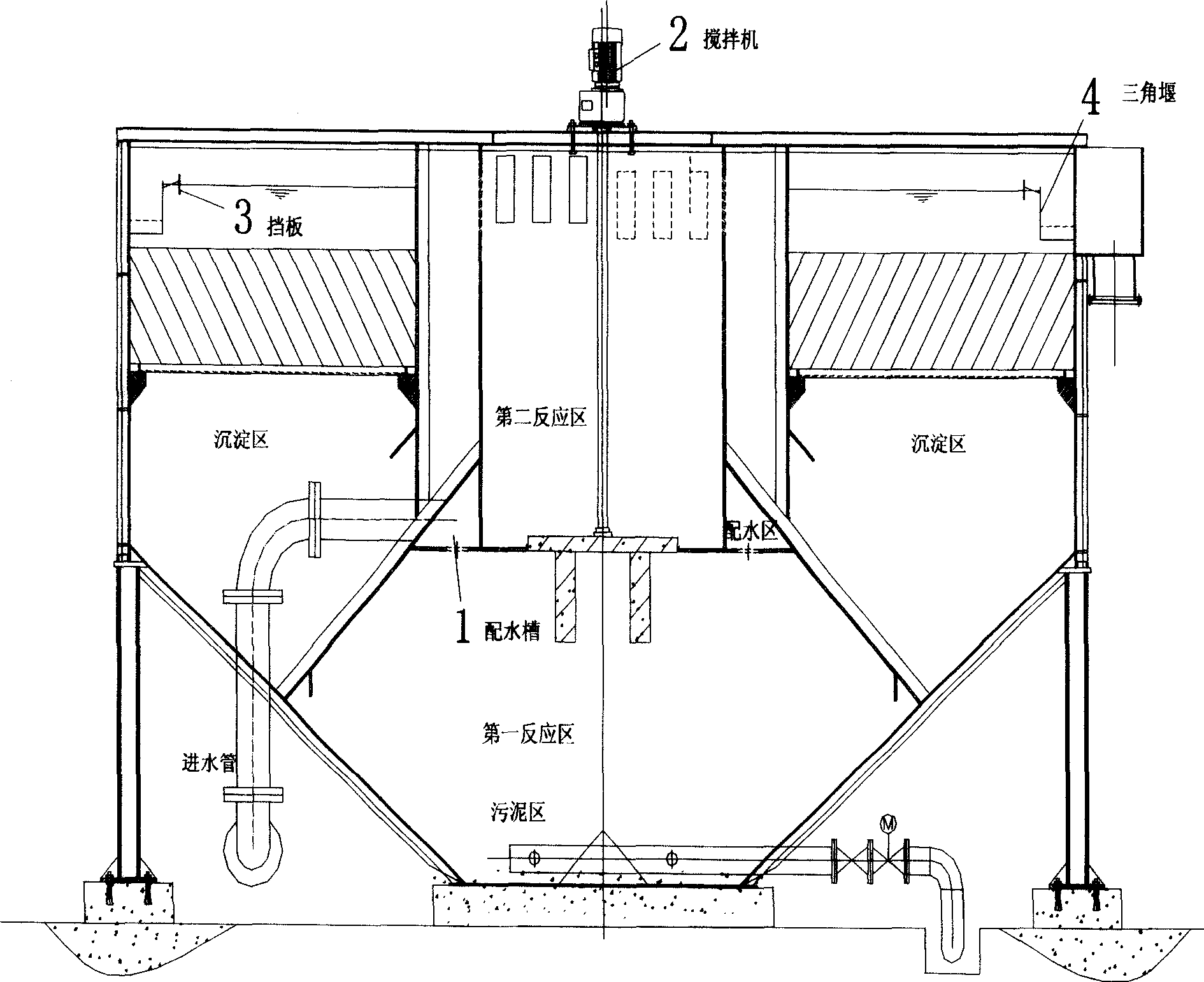

[0027] Such as figure 2 As shown, this embodiment includes: a water distribution area, a reaction area, a sedimentation area, and a sludge area. The reaction area is distributed in the water distribution area, the sludge area is distributed at the bottom of the reaction area, and the sedimentation area is distributed at the upper end of the outer periphery of the reaction area. It also includes an outlet triangular weir 4 and a lifting mixer 2, and the lifting mixer 2 is installed across the reaction zone. The reaction zone includes a first reaction zone and a second reaction zone. The first reaction zone and the sludge zone are combined to share one area, and have a conical bottom. A water distribution tank is provided at the bottom of the second reaction zone, and water is introduced into the water distribution tank through the annular water distribution tank 1 . A baffle plate 3 is installed at the outlet triangular weir. First, change the raw water inlet method, from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com