Utilization method of methanol purge gas

A methanol purge gas, methanol technology, applied in chemical instruments and methods, preparation of organic compounds, catalyst activation/preparation, etc., can solve problems such as unstable production, improve carbon utilization, reduce emissions, and benefit the system stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

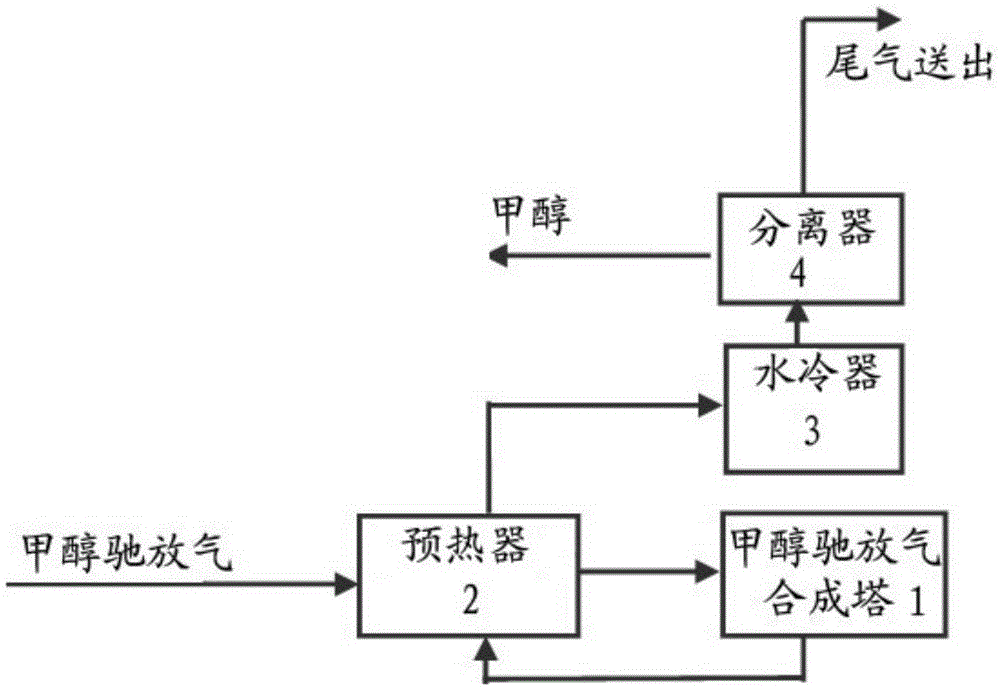

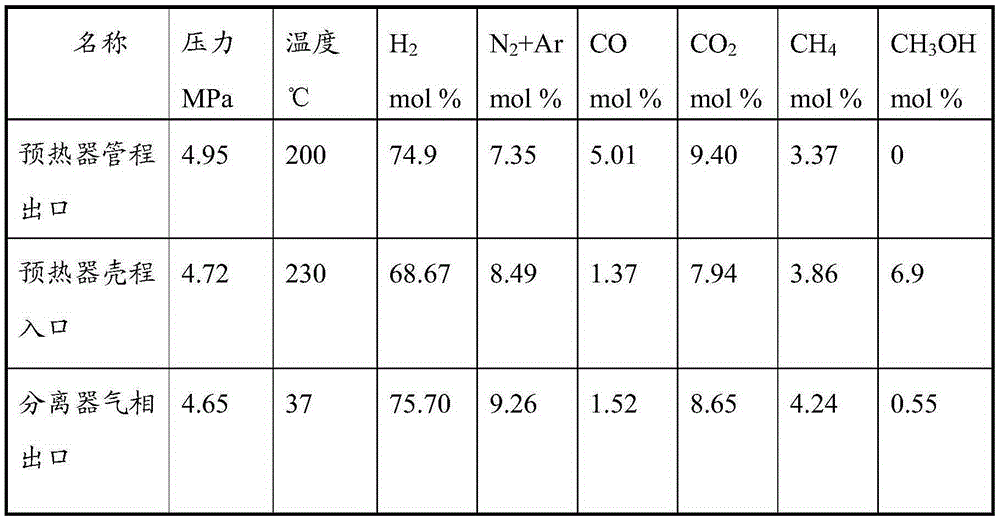

[0055] Send methanol purge gas into figure 1 In the methanol purge gas synthesis unit shown in . The methanol purge gas synthesis tower 1 is a GC-type water-cooled plate synthesis reactor produced by Nanjing Guochang Company, and the catalyst loaded therein is GC-308 catalyst of Nanjing Guochang Company. In the preheater 2, the methanol purge gas enters the tube side, and the synthesis product from the methanol purge gas synthesis tower enters the shell side. The logistics parameters of each position in the system are shown in Table 1.

[0056] Table 1

[0057]

[0058] It can be seen from Table 1 that by adopting the method of the present invention, the total carbon conversion rate of coke oven gas can be increased from the original 92% to over 98%, achieving the purpose of energy saving and emission reduction. At the same time, the invention provides a methanol purge gas synthesis system that can share the burden of the original coke oven gas methanol system in the nor...

Embodiment 2

[0061] The tail gas drawn from the gas phase outlet of the separator in Example 1 was used as the reducing agent for the reduction of the desulfurizing agent in methanol from coke oven gas. The desulfurizer is an iron-manganese desulfurizer, packed in a volume of 50m 3In the desulfurizer tank, the mixed gas of the tail gas and nitrogen is passed into the desulfurizer tank, the hydrogen content in the mixed gas is controlled to be 3-4mol%, and the temperature in the desulfurizer tank is raised to 120 ℃; then gradually increase the feed rate of the tail gas, reduce the feed rate of nitrogen gas, completely cut off the nitrogen gas when the hydrogen content in the mixed gas is increased to about 40mol% within 3 hours, and further remove the iron-manganese desulfurizer in the container After the bed temperature was gradually raised to about 350°C, the reaction was carried out for 30 hours, and the gas space velocity during the reaction was about 80 / h. During the whole reduction p...

Embodiment 3

[0063] The methanol purge gas in Example 1 was used as the reducing agent for the reduction of the desulfurizing agent in the production of methanol from coke oven gas. The desulfurizer is an iron-manganese desulfurizer, packed in a volume of 50m 3 In the desulfurizer tank, the mixed gas of the tail gas and nitrogen is passed into the desulfurizer tank, the hydrogen content in the mixed gas is controlled to be 3-4mol%, and the temperature in the desulfurizer tank is raised to 120 ℃; then gradually increase the inlet of the tail gas, reduce the nitrogen inlet, completely cut off the nitrogen when the hydrogen content in the mixed gas is about 40mol% within 3 hours, and further remove the iron-manganese desulfurizer bed in the container After the temperature was gradually raised to about 350°C, the reaction was carried out for 28 hours, and the gas space velocity during the reaction was about 75 / h. During the whole reduction process, there is no overheating phenomenon. The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com