Air conditioner connecting pipe punching machine

A punching machine and air-conditioning technology, which is applied in the field of punching machines to achieve the effect of eliminating hidden safety hazards, good punching quality and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

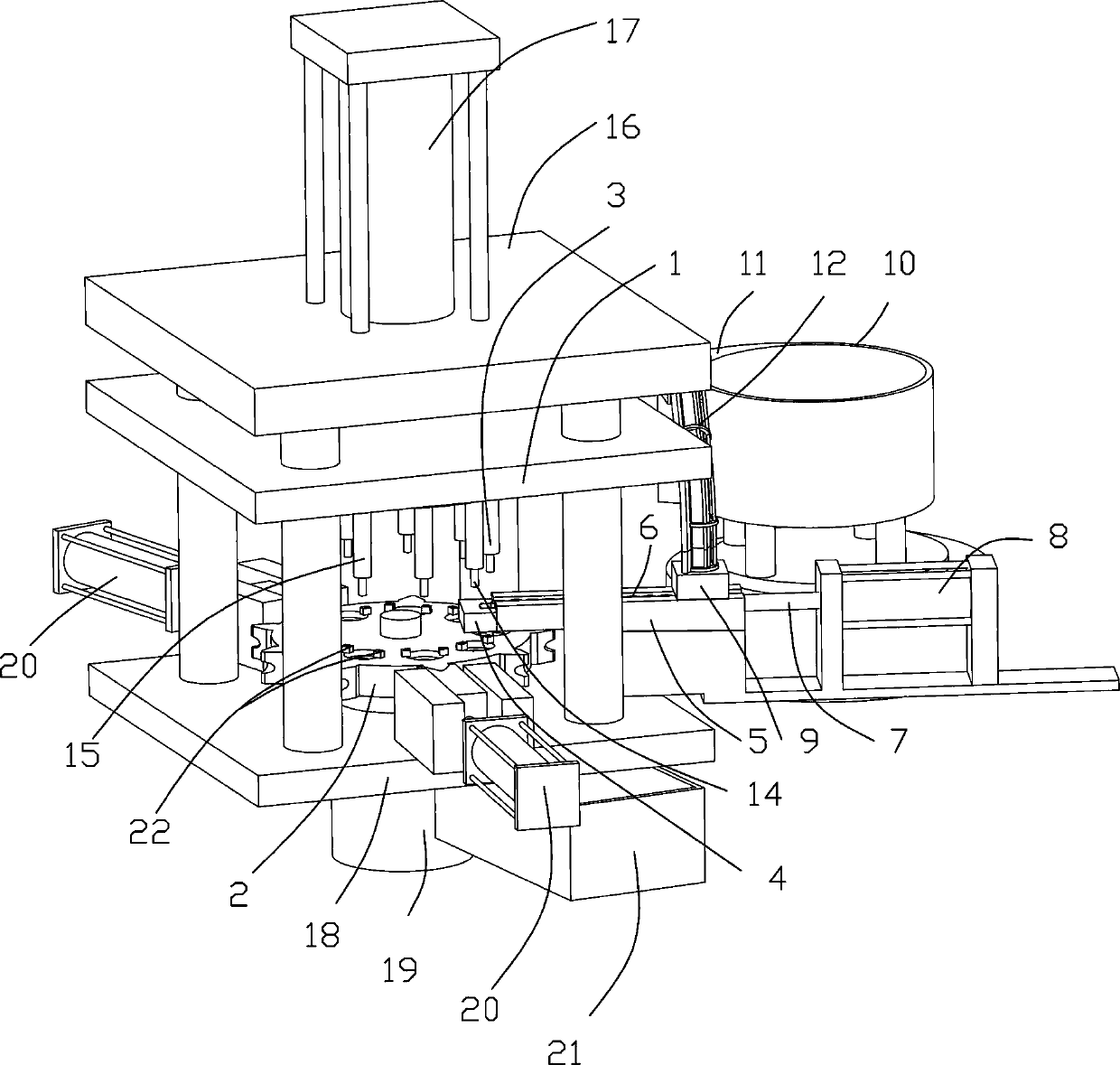

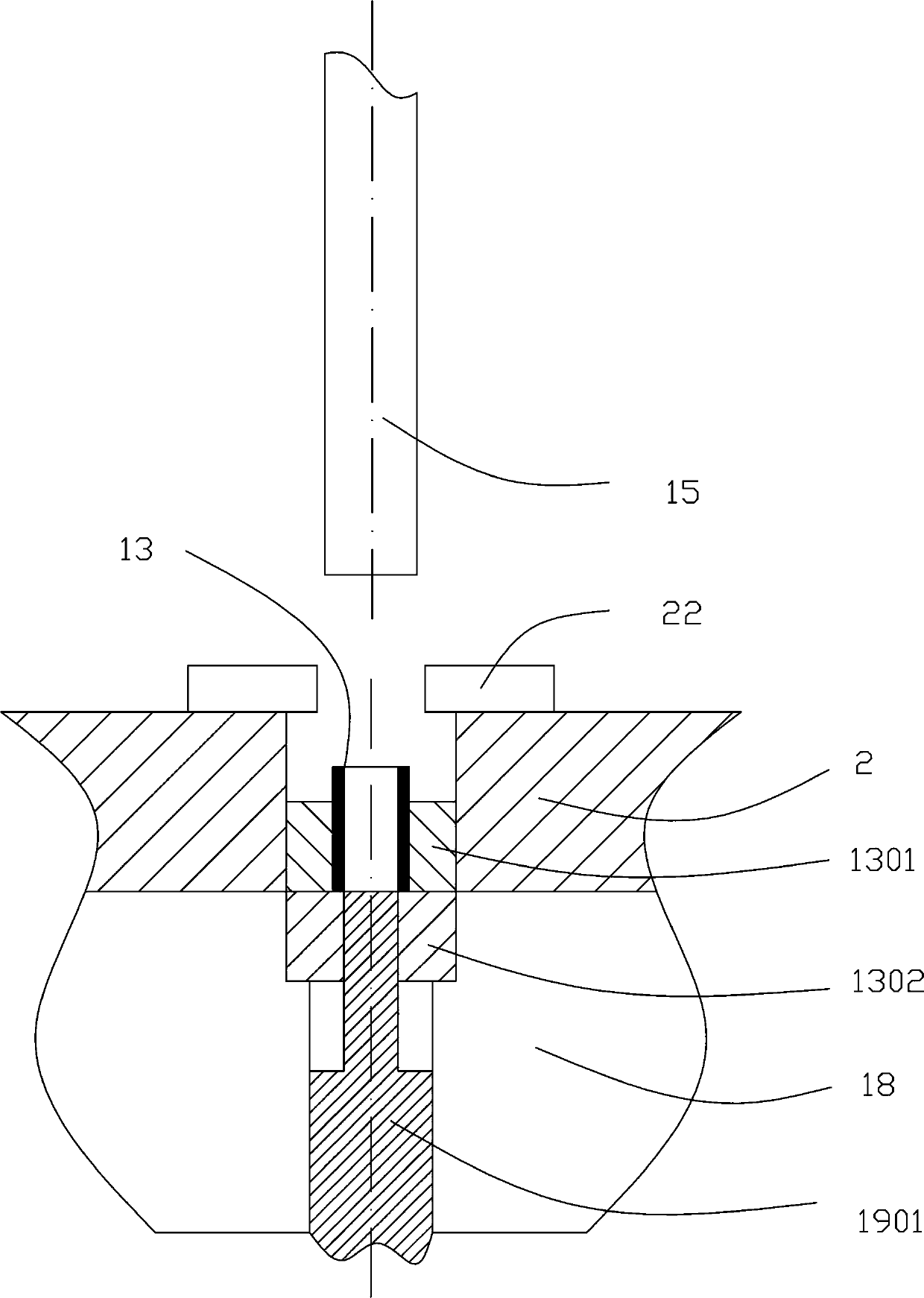

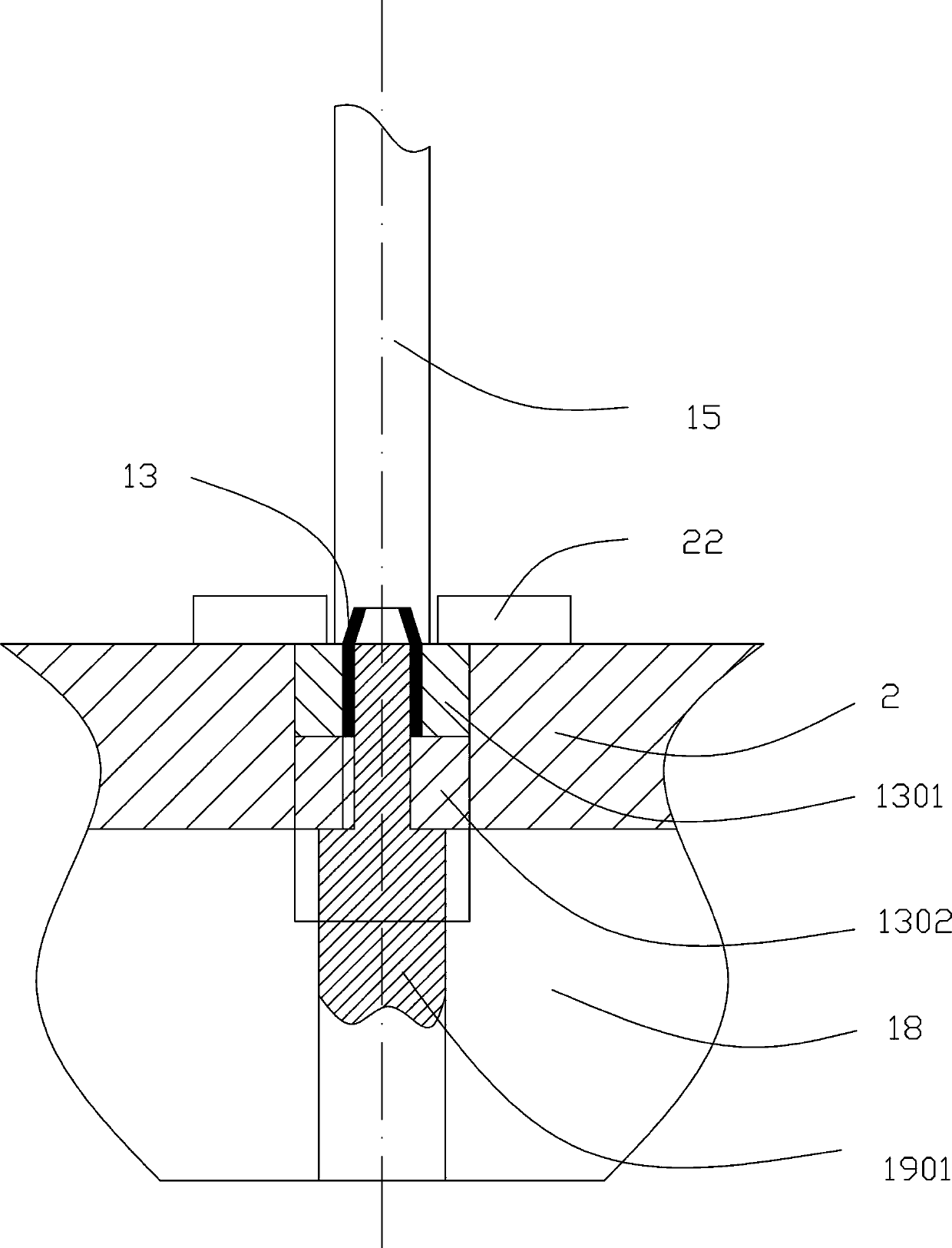

[0030] Such as figure 1 As shown, the punching machine includes a bracket 16, a vertical guide column on the bracket 16, an upper mold base 1 that can be raised and lowered in the vertical direction is provided on the guide pillar, and the bottom of the upper mold base 1 is provided with a punching station Corresponding to multiple stamping dies, there is an intermittent rotating turntable 2 directly below the stamping die. The turntable 2 is provided with positioning holes and positioning molds 1301 corresponding to the position of the stamping die. Below the turntable 2 is provided a fixed on the bracket 16 The fixing plate 18 is provided with a lower mold located below the positioning mold 1301 in the fixing plate 18, and the lower mold includes a sheath 1302 and a jack 1901 inserted in the sheath.

[0031] Preferably, the stamping die includes a plurality of stamping rods 15 corresponding to the stamping process, a feeding pressure rod 3 for feeding, and a discharge pressure ...

Embodiment 2

[0036] Preferably, an automatic feeding device is also provided on the side of the stamping die.

[0037] See figure 1 , The automatic feeding device includes a horizontal pushing mechanism, a blanking mechanism, and a vibration feeding mechanism.

[0038] The vibrating feeding mechanism includes a vibrating plate 10 on which is provided with a transfer platform 11 which is connected to the squirrel cage guide rail 12.

[0039] The horizontal pushing mechanism includes a horizontal guide rail 5 arranged below the exit of the squirrel cage guide rail 12. The horizontal guide rail 5 is provided with a through groove 6 for conveying and connecting pipes. One end of the through groove 6 is inserted with a push rod 7 driven intermittently by an air cylinder 8. The other end is connected with the positioning block 4 of the blanking mechanism.

[0040] See figure 1 with Figure 7 , The vertical positioning block 4 of the blanking mechanism is suspended between the upper mold base 1 and the...

Embodiment 3

[0047] Such as Figure 2-Figure 4 As shown, combined with Example 1 and Example 2, the detailed description of the stamping process is as follows,

[0048] First, the upper die set 1 is driven by the upper pressure cylinder 17 to drive the punching rod 15, the discharge pressure rod 14 and the feeding pressure rod 3 are pressed down at the same time, and while the nozzle 13 in the turntable 2 is punched, a punching is completed simultaneously The discharge of the finished product and the feeding of 13 raw materials are taken over.

[0049] Secondly, the turntable rotates a station (each station corresponds to a positioning hole and a stamping die), and the unprocessed pipe is transferred to the first stamping station for stamping. Figure 2-Figure 4 As shown, the nozzle 13 is first in the positioning mold 1301. The sheath 1302 under the positioning mold 1301 axially blocks the nozzle 13 so that it cannot fall. The outer diameter of the front end of the ejector rod 1901 inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com