Pass design method of continuous rolling machine

A technology of pass design and continuous rolling mill, applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., to achieve the effect of ensuring accuracy, improving efficiency and solving cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

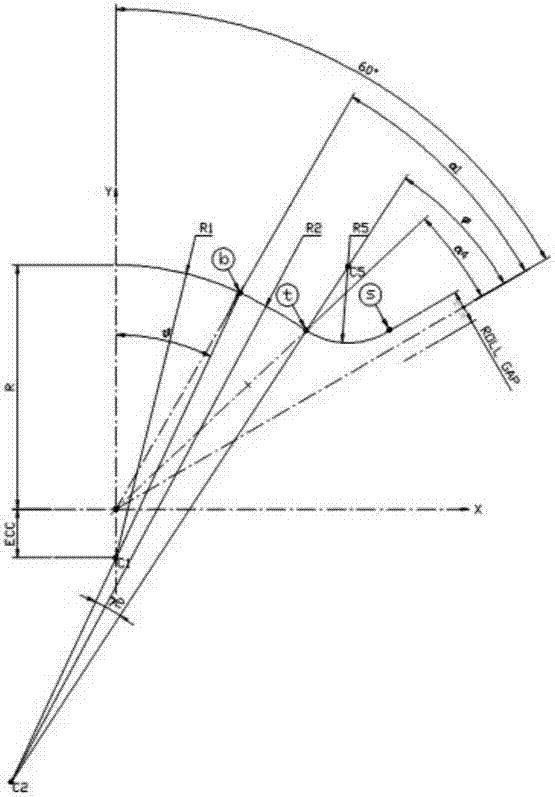

[0023] In view of the experience in the pass design of the limited mandrel continuous rolling mill (MPM: the abbreviation of Multi-Stand Pipe Mill), the pass design of the PQF continuous rolling mill was successfully designed to meet the needs of the new pass.

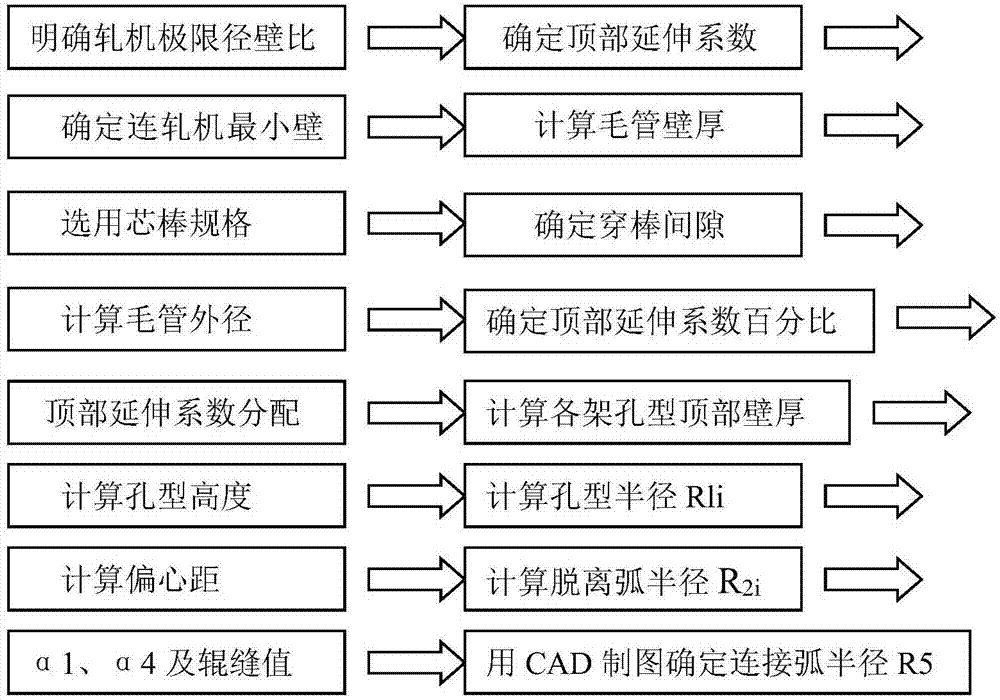

[0024] According to the characteristics of the produced products, the present invention redesigns the pass type according to the distribution method of the groove bottom extension coefficient on the basis of following the original rolling theory. For the new design pass, the rolling table is calculated by changing the original digital model to adapt to the change of the pass, to roll the target wall thickness product, only the continuous rolling pass is changed, and other areas are only adjusted.

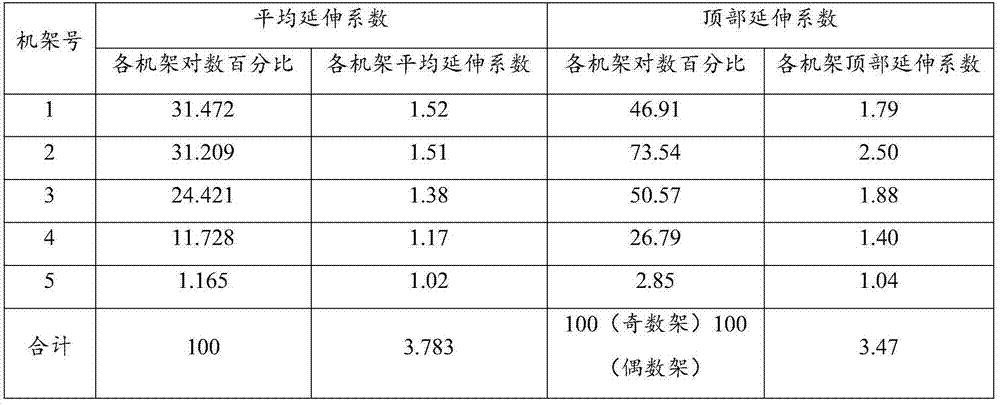

[0025] In the preferred embodiment of the present invention, a 5-stand PQF continuous pipe mill (i=5) is selected as an example, and the technical solution of the present invention will be described in detail below with refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com