High-concentration compound florfenicol injection, and preparation method and application thereof

A technology of compound florfenil and florfenicol, which is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and respiratory system diseases, can solve the problems of large injection volume and inconvenient use, and achieves small injection volume, Easy to use, effective and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

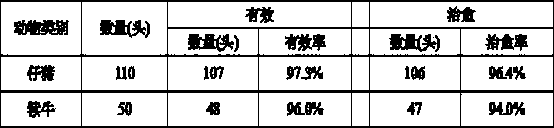

Image

Examples

Embodiment 1

[0025] Weigh 300 g injection-grade florfenicol raw material and 27.4 g flunixin meglumine raw material, add 200 ml pharmaceutical grade glycerin formal, 200 ml pharmaceutical grade glycerol acetate, 100 ml pharmaceutical grade polyethylene glycol 400, stir Completely infiltrate the raw material drug, then add 250 ml of pharmaceutical grade 1-methyl-2-pyrrolidone, heat to 50 °C, stir well to dissolve, let cool to room temperature, add pharmaceutical grade propylene glycol to 1000 ml, mix well, add Pharmaceutical injection grade activated carbon 4 g, mix well, absorb, filter, subpackage, sterilize, ready to use.

Embodiment 2

[0027] Weigh 400 g of injection-grade florfenicol raw materials and 36.5 g of flunixin meglumine raw materials, add 100 ml of pharmaceutical grade propylene glycol, 100 ml of pharmaceutical grade glycerol acetate, stir to completely infiltrate the raw materials, and then add pharmaceutical grade 1- Add 300 ml of methyl-2-pyrrolidone, add 250 ml of pharmaceutical grade glycerin formal, heat to 50 ℃, stir well to dissolve, let cool to room temperature, add pharmaceutical grade glycerin formal to make up to 1000 ml, mix well, add medicine Injection-grade activated carbon 4g, mix well, absorb, filter, subpackage, sterilize, and you get it.

Embodiment 3

[0029] Take 450 g of injection-grade florfenicol raw materials and 41.1 g of flunixin meglumine raw materials, add 50 ml of pharmaceutical grade propylene glycol, 100 ml of pharmaceutical grade glycerol acetate, and then add 350 ml of pharmaceutical grade 1-methyl-2-pyrrolidone , add 250 ml of pharmaceutical grade glycerin formal, heat to 50 ℃, stir well to dissolve, let cool to room temperature, add pharmaceutical grade glycerin formal to 1000 ml, mix well, add pharmaceutical injection grade activated carbon 4 g, mix well , adsorption, filtration, packaging, sterilization, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com