Preparation method of low-fat high-dietary-fiber grain sausage

A technology with high dietary fiber and dietary fiber, applied in the field of food processing, can solve the problems of immature dietary fiber sausage, rough sausage taste, poor sensory effect, etc., to improve quality and sensory properties, improve nutritional and health functions, reduce The effect of fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

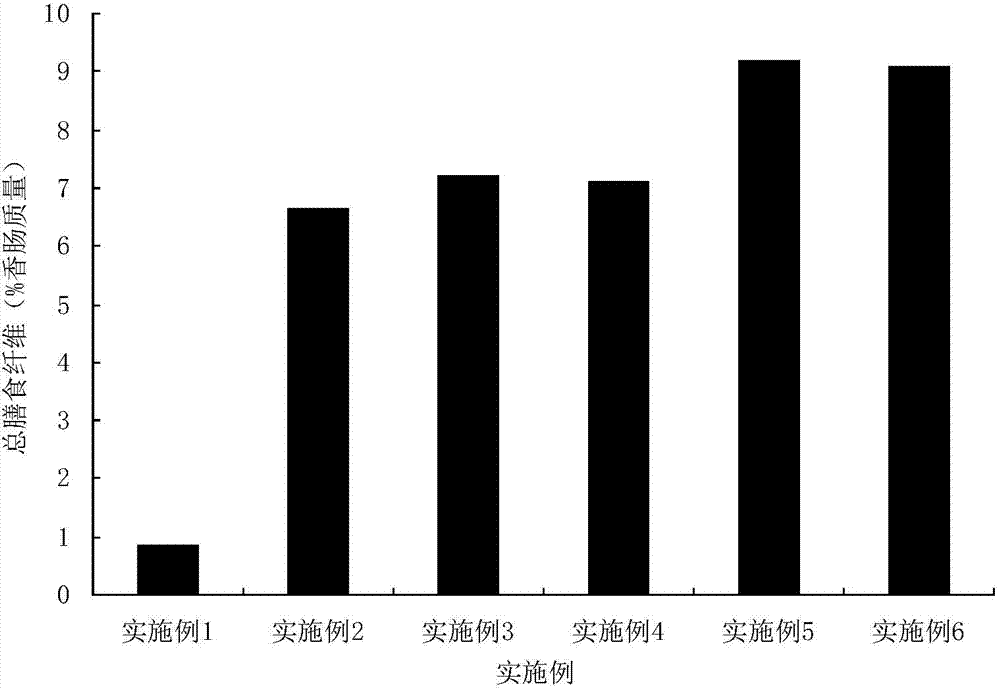

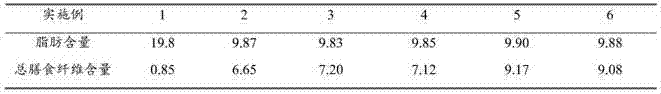

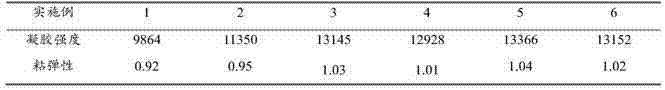

Examples

Embodiment 1

[0033] This example provides an existing method for preparing dietary fiber sausage (the referenced patent application number is 201110312443.0). The weight ratio of the raw material components contained in the enema is: 100 parts of pork (80 lean meat + 20 fat meat), soluble dietary 0.9 parts of fiber, 6.3 parts of starch, 0.6 parts of carrageenan, 0.1 parts of pepper, 0.6 parts of five-spice powder, 2.1 parts of white sugar, 0.05 parts of monosodium glutamate, 0.42 parts of Daqu wine, 2.9 parts of refined salt, 0.01 parts of sodium nitrite, soluble dietary fiber used For self-extracted apple pomace dietary fiber, the preparation method of enema comprises the following steps:

[0034] 1) Pork processing: deboning, skinning, removing fat, tendons, blood clots and lymph nodes, then cutting lean meat into fist-sized chunks and fat meat into chunks about 1 cm square;

[0035] 2) Marinating: Sauce pork is evenly mixed with refined salt, and marinated at 1°C for 30 hours;

[0036]...

Embodiment 2

[0043] 90 parts of marinated refined meat and 10 parts of back fat were made into meat fillings using a meat grinder with 8mm mesh, and 10 parts of ice water were added in stages. Put chopped lean meat, oatmeal dietary fiber (unmodified), minced backfat and other auxiliary materials into a mixer for 10-15 minutes; the temperature is controlled below 10°C, and the formula for adding auxiliary materials is: oat meal Fiber (unmodified) 8 parts, starch 5 parts, salt 3 parts, sugar 1 part, monosodium glutamate 0.5 parts, five-spice powder 0.5 parts, pepper 0.5 parts, carrageenan 0.5 parts, phosphate 0.3 parts, nitrite 0.015 parts . The above-mentioned mixed raw materials were marinated at 4°C for 24 hours. Enema the uniformly mixed meat stuffing through an automatic sausage enema machine, using natural casings of pigs or sheep; bake the above enema at 60-70°C for 0.5-1h; put the baked enema in boiling water for 40-50min ; Cool the above-mentioned sausages to 10-15°C, vacuum pack ...

Embodiment 3

[0045]90 parts of marinated refined meat and 10 parts of back fat were made into meat fillings using a meat grinder with 8mm mesh, and 10 parts of ice water were added in stages. Put chopped lean meat, modified oat dietary fiber, ground backfat and other auxiliary materials into a mixer for 10-15 minutes; the temperature is controlled below 10°C, and the formula for adding auxiliary materials is: modified oat meal 8 parts of fiber, 5 parts of starch, 3 parts of salt, 1 part of sugar, 0.5 parts of monosodium glutamate, 0.5 parts of allspice powder, 0.5 parts of pepper, 0.5 parts of carrageenan, 0.3 parts of phosphate, and 0.015 parts of nitrite. The above-mentioned mixed raw materials were marinated at 4°C for 24 hours. Enema the evenly mixed meat filling through an automatic sausage enema machine, using natural casings of pigs or sheep; bake the above enema at 60-70°C for 0.5-1h; put the baked enema in boiling water for 40-50min ; Cool the above-mentioned sausages to 10-15°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com