Nanoscale docosahexaenoic acid emulsion and preparation method thereof

A technology of docosahexaenoic acid and carbhexaenoic acid emulsion, which is applied in the directions of emulsion transportation, food preparation, pharmaceutical formulation, etc., can solve the problem of difficulty in controlling the particle size of emulsion oil droplets and unstable quality of microcapsule powder. , the key process control points are not clear and other problems, to achieve good slow release function and targeting, good antioxidant effect, no toxic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

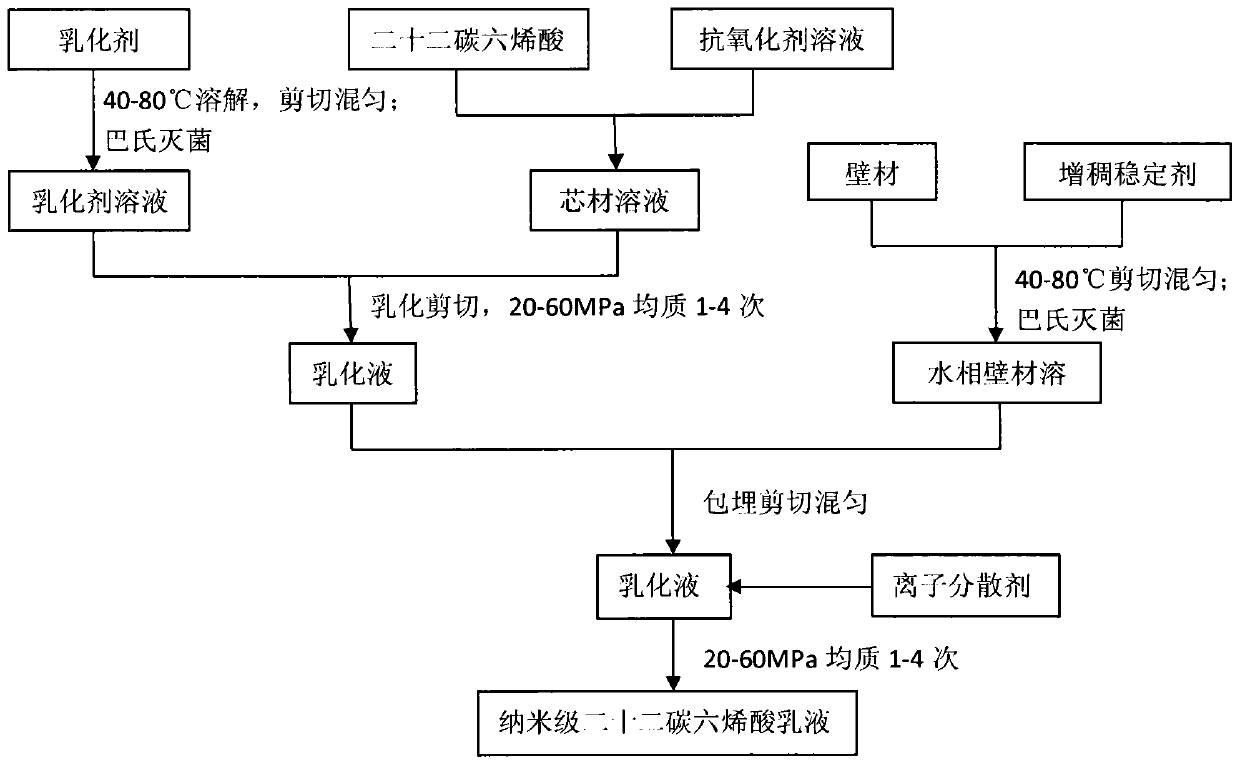

Method used

Image

Examples

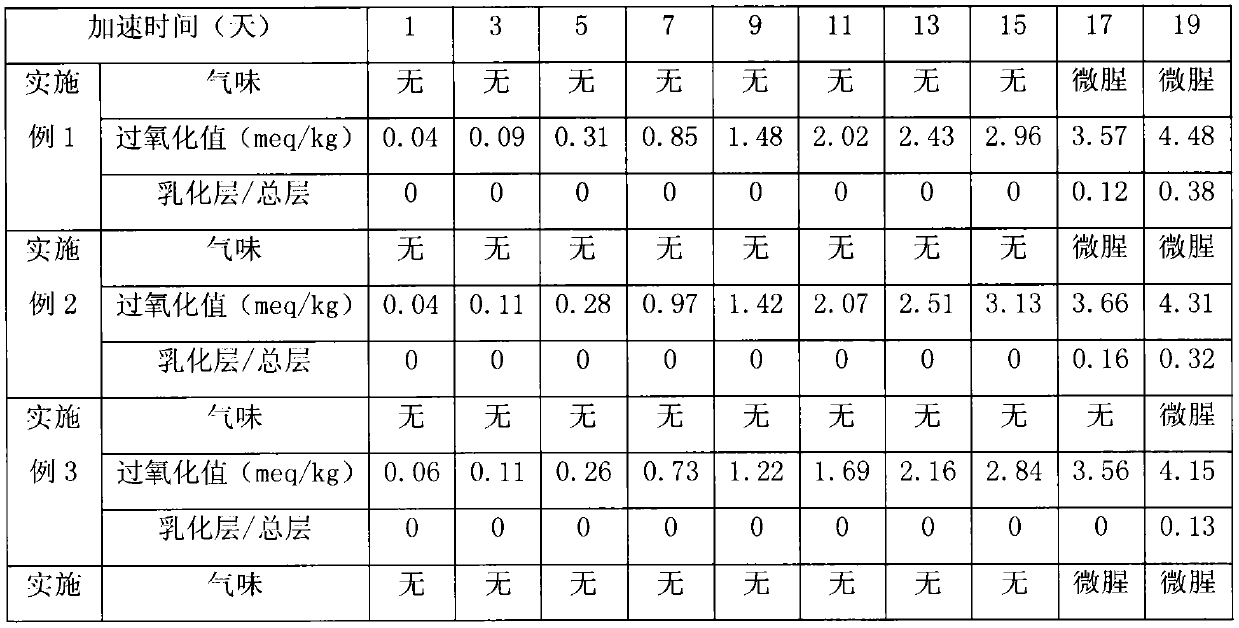

Embodiment 1

[0035] Weigh 70g of emulsifier (60g of modified starch, 10g of lecithin) and add it into deionized water, heat and mix at 40°C evenly, use a high-speed shearer to shear and stir the emulsifier to dissolve, and the shear rate is controlled at 5600 rpm. The cutting time was 10 minutes, followed by pasteurization, and the sterilized emulsifier solution was cooled to 30°C for later use. Dissolve 0.35g of antioxidants (including 0.15g of natural vitamin E and 0.2g of ascorbyl palmitate) in a small amount of docosahexaenoic acid oil at 50°C, cut until completely dissolved, cool to 30°C, and add 300g of mixed grease with 50% docosahexaenoic acid content, fully sheared and mixed to obtain a core material solution, then mixed the core material solution with an emulsifier solution, emulsified and sheared, and transferred to a high-pressure homogenizer for homogenization 1 times, the pressure is 40MPa. Add 730g of pasteurized wall material and stabilizer (including 410g of whey protein ...

Embodiment 2

[0037] Weigh 100g of emulsifier (sodium caseinate 100g), add it to deionized water, heat and mix at 50°C, and use a high-speed shearer to shear the emulsifier, the shear rate is controlled at 3000 rpm, and the shear time is 40 Minutes, followed by pasteurization, and cooling the sterilized emulsifier solution to 30°C for later use. Dissolve 0.4g of antioxidants (including 0.2g of natural vitamin E, 0.1g of rosemary extract, and 0.1g of tea polyphenols) in vegetable oil at 80°C, cut until completely dissolved, and add 35% 20% after cooling to 30°C 400g of mixed grease with Dicahexaenoic acid content is fully sheared and mixed to obtain a core material solution, then the core material solution is mixed with an emulsifier solution, emulsified and sheared, and transferred to a high-pressure homogenizer for homogenization 3 times at a pressure of 40MPa . Add 660g of pasteurized wall material and stabilizer (including 260g of desalted whey powder, 8060g of WPC, 50g of sucrose, 230g...

Embodiment 3

[0039]Weigh 40g of emulsifier (35g of sodium caseinate, 5g of modified starch), add it into deionized water, heat and mix evenly at 50°C, use a high-speed shearer to shear the emulsifier, and the shear rate is controlled at 2000 rpm, The shearing time is 20 minutes, followed by pasteurization, and the sterilized emulsifier solution is cooled to 30° C. for use. Dissolve 0.8g of antioxidants (including 0.5g of natural vitamin E, 0.2g of ascorbyl palmitate, and 0.1g of tea polyphenols) in vegetable oil at 60°C, cut until completely dissolved, and add 38% twenty-two after cooling to 30°C 400g of mixed grease with carbasexaenoic acid content was fully sheared and mixed to obtain a core material solution, then the core material solution was mixed with an emulsifier solution, emulsified and sheared, then transferred to a high-pressure homogenizer for homogenization 4 times at a pressure of 40 MPa. Add 810g of pasteurized wall material (including 260g of whey protein isolate, 8080g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com