Soil loosening device for potted plants

A plant and ripper technology, applied in the field of agricultural machinery, can solve problems such as water leakage, and achieve the effects of avoiding leakage loss, facilitating absorption, and increasing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

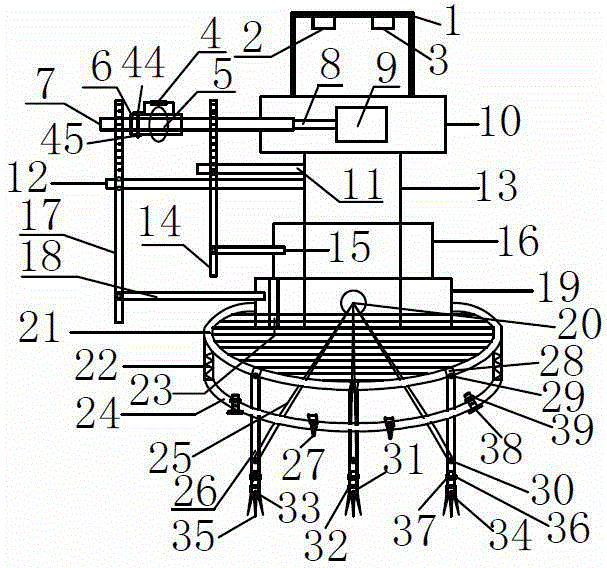

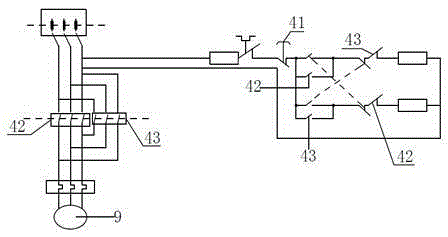

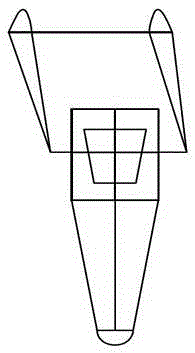

[0033] Embodiment 1: as Figure 1-8 As shown, a potted plant loosening device includes a handle 1, a main switch 2, a control switch 3, a handle 4, a gear 5, a sleeve III 6, a connecting shaft III 7, a central axis 8, a stepping motor 9, and a motor box 10 , straight rod Ⅰ11, straight rod Ⅱ12, central rod 13, rack Ⅰ14, connecting shaft Ⅰ15, sleeve Ⅰ16, rack Ⅱ17, connecting shaft Ⅱ18, sleeve Ⅱ19, fixed knob Ⅰ20, ring base Ⅰ21, spring 22, groove 23 , ring base Ⅱ24, oblique rod 25, ripper 26, spring latch 27, anti-swing guard 28, pin 29, fixed knob Ⅱ30, sleeve Ⅳ31, fixed knob Ⅲ32, fixed knob Ⅳ33, ripper tip Ⅰ34, ripper tip Ⅱ35, bolt Ⅰ36, nut Ⅰ37, bolt Ⅱ38, nut Ⅱ39, sheet 40, circuit main switch 41, forward rotation switch 42, reverse rotation switch 43, bolt Ⅲ44, nut Ⅲ45; the handle 1 is fixed on the upper part of the motor box 10, and the total The switch 2 is connected with the main switch 41 of the circuit, the control switch 3 is connected with the forward rotation switch 42...

Embodiment 2

[0039] Embodiment 2: as Figure 1-8As shown, a potted plant loosening device includes a handle 1, a main switch 2, a control switch 3, a handle 4, a gear 5, a sleeve III 6, a connecting shaft III 7, a central axis 8, a stepping motor 9, and a motor box 10 , straight rod Ⅰ11, straight rod Ⅱ12, central rod 13, rack Ⅰ14, connecting shaft Ⅰ15, sleeve Ⅰ16, rack Ⅱ17, connecting shaft Ⅱ18, sleeve Ⅱ19, fixed knob Ⅰ20, ring base Ⅰ21, spring 22, groove 23 , ring base Ⅱ24, oblique rod 25, ripper 26, spring latch 27, anti-swing guard 28, pin 29, fixed knob Ⅱ30, sleeve Ⅳ31, fixed knob Ⅲ32, fixed knob Ⅳ33, ripper tip Ⅰ34, ripper tip Ⅱ35, bolt Ⅰ36, nut Ⅰ37, bolt Ⅱ38, nut Ⅱ39, sheet 40, circuit main switch 41, forward rotation switch 42, reverse rotation switch 43, bolt Ⅲ44, nut Ⅲ45; the handle 1 is fixed on the upper part of the motor box 10, and the total The switch 2 is connected with the main switch 41 of the circuit, the control switch 3 is connected with the forward rotation switch 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com