A drive control method for a three-phase single-winding bearingless motor

A bearingless motor, single-winding technology, used in AC motor control, control systems, electrical components, etc., can solve the problem of three-phase single-winding bearingless motor drive control that has not been reported, bearingless motors cannot achieve suspension operation, two sets of The winding angle is difficult to determine and other problems, to achieve the effects of excellent dynamic and static characteristics, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

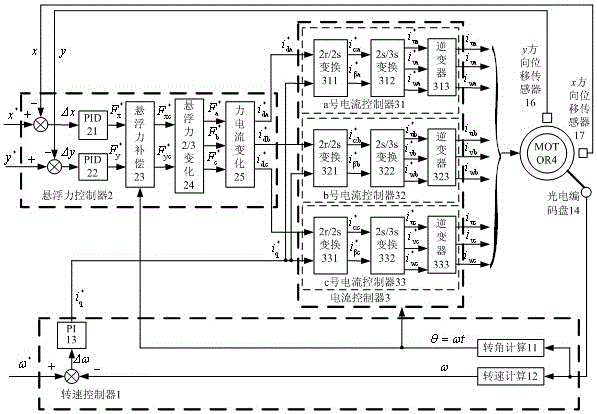

[0015] see figure 1 , divide a set of armature windings of the three-phase single-winding bearingless motor 4 into three areas a, b, and c on average, and perform closed-loop control on the speed of the three-phase single-winding bearingless motor 4 to obtain a current signal , through the closed-loop control of the levitation force, three current signals are obtained , with ; respectively with , with Three sets of current control signals are formed, which pass through current controllers No. a, No. B and No. C respectively, and three inverters 313, 323 and 333 of No. a, No. b and No. The windings are independently controlled to realize the self-suspension and rotation of the rotor at the same time. The specific implementation steps are as follows:

[0016] 1) Use the x-direction displacement sensor 17 to detect the actual displacement value of the radial level of the rotor of the three-phase single-winding bearingless motor , using the y-direction displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com