Noise reduction package of distributed feedback fiber laser

A fiber laser, distributed feedback technology, applied in the direction of laser components, etc., can solve the problems of laser disturbance, destruction of narrow line width and low noise advantages, and the inability to realize industrial packaging, so as to reduce thermal noise and ensure tensile performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

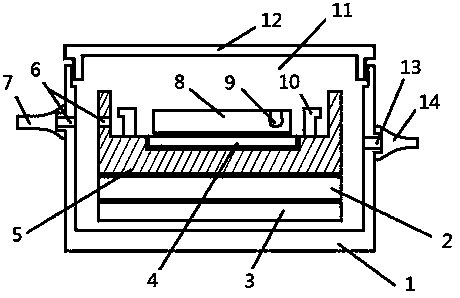

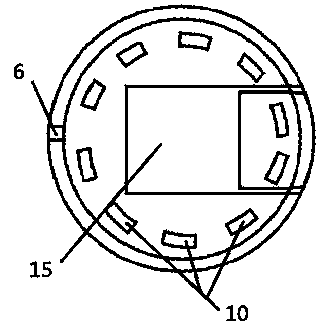

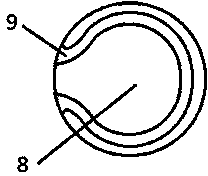

[0021] Such as figure 1 As shown, a distributed feedback type fiber laser noise reduction packaging structure, which includes a hollow cylindrical shell 1, a shell cover 12 matched with the open end of the shell 1, and a curved plastic metal base 8 is arranged in the shell 1 ,Such as image 3 As shown, a C-shaped molding groove 9 is provided on the upper surface of the curved molding metal base 8, and the bending diameter of the molding groove 9 is controlled between 25 mm and 45 mm. The relationship between bending diameter and line width is as follows Figure 6As shown, it can be seen that when the diameter is between 25mm and 45mm, the linewidth value of the laser can be effectively compressed, the bending diameter is too large or the conventional free placement state will make the laser linewidth wider, and the bending diameter is too small. It will cause excessive fiber loss and affect the output power. This patent has adopted 30mm diameter and obtained good effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com