Preparation method of copper-doped Li4Ti5O12-TiO2 regulation and control composite material

A composite material and element technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low conductivity, low charge and discharge capacity, poor rate performance, etc., to achieve high power density, high energy, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A copper-doped control Li 4 Ti 5 o 12 -TiO 2 The preparation method of composite material, the steps are as follows:

[0022] 1) Add 3.40g of tetrabutyl titanate into 20mL of ethanol and stir vigorously to prepare solution A;

[0023] 2) Add 0.54g LiOH to 15mL distilled water and stir vigorously until it is completely dissolved to obtain solution B;

[0024] 3) Under strong stirring, slowly add solution B to solution A, stir for half an hour and then add copper acetate, the molar ratio of titanium, lithium and copper in the mixture is Li 4-x Cu x Ti 5 o 12 , where x=0.05, continue stirring for one hour to obtain a mixed solution;

[0025] 4) Put the above mixed solution in a high-pressure reactor and react at 160°C for 12 hours to obtain a precursor;

[0026] 5) The above precursor was calcined at 600°C for 4 hours to obtain copper-doped regulated Li 4 Ti 5 o 12 -TiO 2 composite material.

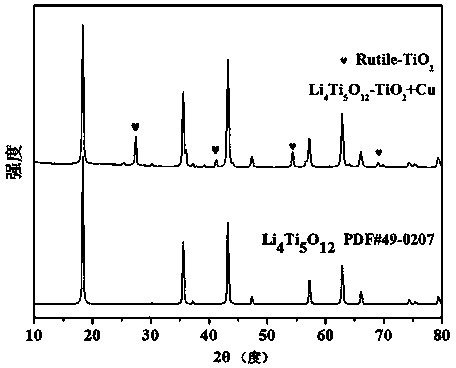

[0027] figure 1 for Li 4 Ti 5 o 12 -TiO 2 and Cu elements reg...

Embodiment 2

[0032] A copper-doped control Li 4 Ti 5 o 12 -TiO 2 The preparation method of composite material, the steps are as follows:

[0033] 1) Add 4.60g of tetrabutyl titanate to 20mL of ethanol and stir vigorously to prepare solution A;

[0034] 2) Add 0.56g LiOH to 20mL distilled water, stir vigorously until completely dissolved to obtain solution B;

[0035] 3) Under strong stirring, slowly add solution B to solution A, stir for half an hour and then add copper acetate, the molar ratio of titanium, lithium and copper in the mixture is Li 4-x Cu x Ti 5 o 12 , where x=0.05, continue stirring for one hour to obtain a mixed solution;

[0036] 4) Put the above mixed solution in a high-pressure reactor and react at 160°C for 24 hours to obtain a precursor;

[0037] 5) The above precursor was calcined at 600°C for 6h to obtain copper-doped regulated Li 4 Ti 5 o 12 -TiO 2 composite material.

[0038] The as-prepared doped copper elements control Li 4 Ti 5 o 12 -TiO 2 The...

Embodiment 3

[0040] A copper-doped control Li 4 Ti 5 o 12 -TiO 2 The preparation method of composite material, the steps are as follows:

[0041] 1) Add 5.40g of tetrabutyl titanate into 15mL of ethanol and stir vigorously to prepare solution A;

[0042] 2) Add 0.54g LiOH to 20mL distilled water, stir vigorously until completely dissolved to obtain solution B;

[0043] 3) Under strong stirring, slowly add solution B to solution A, stir for half an hour and then add copper acetate, the molar ratio of titanium, lithium and copper in the mixture is Li 4-x Cu x Ti 5 o 12 , where x=0.1, continue stirring for one hour to obtain a mixed solution;

[0044] 4) Put the above mixed solution in a high-pressure reactor and react at 160°C for 12 hours to obtain a precursor;

[0045] 5) The above precursor was calcined at 600°C for 4 hours to obtain copper-doped regulated Li 4 Ti 5 o 12 -TiO 2 composite material.

[0046] The as-prepared doped copper elements control Li 4 Ti 5 o 12 -TiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com