Sea urchin like NiCo2S4 electrode material solvothermal synthesis method

An electrode material, solvothermal technology, applied in the field of electrochemical energy storage, to achieve the effects of high purity, good crystallinity, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 0.6mmolNiCl 2 ·6H 2 O, 1.2 mmol CoCl 2 ·6H 2 O was dissolved in 40ml deionized water, and then 8mmolCS(NH 2 ) 2 , Stir with a magnetic stirrer to make it mix evenly, then add 40ml diethanolamine, continue to stir with a magnetic stirrer until a clear solution.

[0027] (2) Transfer the solution in step (1) to a 100ml autoclave lined with polytetrafluoroethylene, heat to 140°C, and keep at constant temperature for 12h.

[0028] (3) Bring the temperature of the reaction kettle down to normal temperature, wash the product in step (2) several times with deionized water and ethanol, and then transfer the reactant to a 60°C oven for drying.

[0029] (4) NiCo obtained in step (3) 2 S 4 Electrode materials were characterized and tested for electrochemical performance.

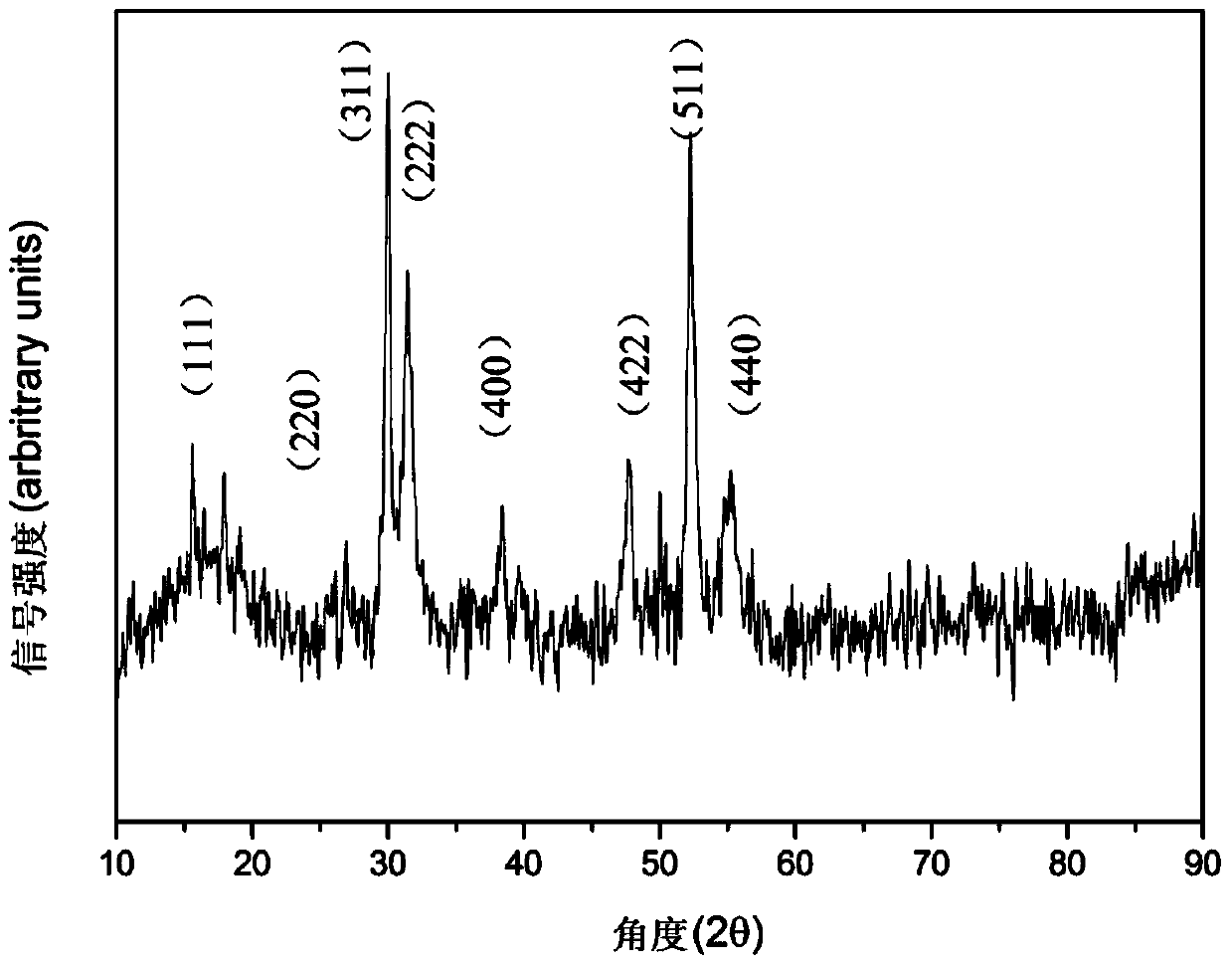

[0030] Such as figure 1 As shown, the diffraction peaks in the XRD pattern of the material and the NiCo 2 S 4 (111), (220), (311), (222), (400), (422), (511), (440) crystal faces of (JCPDS No. 24-...

Embodiment 2

[0040] (1) 0.6mmolNiCl 2 ·6H 2 O, 1.2 mmol CoCl 2 ·6H 2 O was dissolved in 40ml deionized water, and then 8mmolCS(NH 2 ) 2 , Stir with a magnetic stirrer to make it mix evenly, then add 40ml diethanolamine, continue to stir with a magnetic stirrer until a clear solution.

[0041] (2) The solution in step (1) was transferred to a 100ml autoclave with a polytetrafluoroethylene liner, heated to 160°C, and kept at a constant temperature for 12h.

[0042] (3) Bring the temperature of the reaction kettle down to normal temperature, wash the product in step (2) several times with deionized water and ethanol, and then transfer the reaction product to a 60°C oven for drying.

[0043] (4) NiCo obtained in step (3) 2 S 4 Electrode materials were characterized and tested for electrochemical performance.

Embodiment 3

[0045] (1) 0.6mmolNiCl 2 ·6H 2 O, 1.2 mmol CoCl 2 ·6H 2 O was dissolved in 40ml deionized water, and then 8mmolCS(NH 2 ) 2 , Stir with a magnetic stirrer to make it mix evenly, then add 40ml diethanolamine, continue to stir with a magnetic stirrer until a clear solution.

[0046] (2) Transfer the solution in step (1) to a 100ml autoclave lined with polytetrafluoroethylene, heat to 180°C, and keep at constant temperature for 12h.

[0047] (3) Bring the temperature of the reaction kettle down to normal temperature, wash the product in step (2) several times with deionized water and ethanol, and then transfer the reactant to a 60°C oven for drying.

[0048] (4) NiCo obtained in step (3) 2 S 4 Electrode materials were characterized and tested for electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com