Method for simulating thermal characteristic numerical value of heavy numerical control floor type boring and milling machine

A numerical simulation, milling and boring machine technology, applied in the field of analysis, can solve the problems of lack of numerical simulation and numerical simulation of thermal characteristics of the whole machine of heavy-duty CNC floor milling and boring machines, and lack of numerical simulation of thermal characteristics of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The invention provides a numerical simulation method for the thermal characteristics of a heavy-duty numerical control floor milling and boring machine. The numerical simulation method performs numerical simulation of the thermal characteristics of the machine tool as a whole, and then combines the contact thermal resistance of the joint surface of each component and the oil film of the static pressure guide rail. Heat generation effectively improves the accuracy and precision of the analysis results. The following takes the TK6916DA heavy-duty CNC floor-type milling and boring machine as an example, combined with this method for detailed explanation:

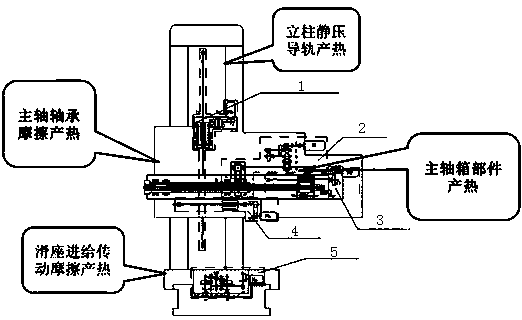

[0069] First, analyze the heat source distribution of TK6916DA, such as figure 1 As shown, the heat source distribution includes: heat generated by the friction of the spindle bearing, heat generated by the friction of the slide feed drive, heat generated by the column static pressure guide rail, and heat generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com