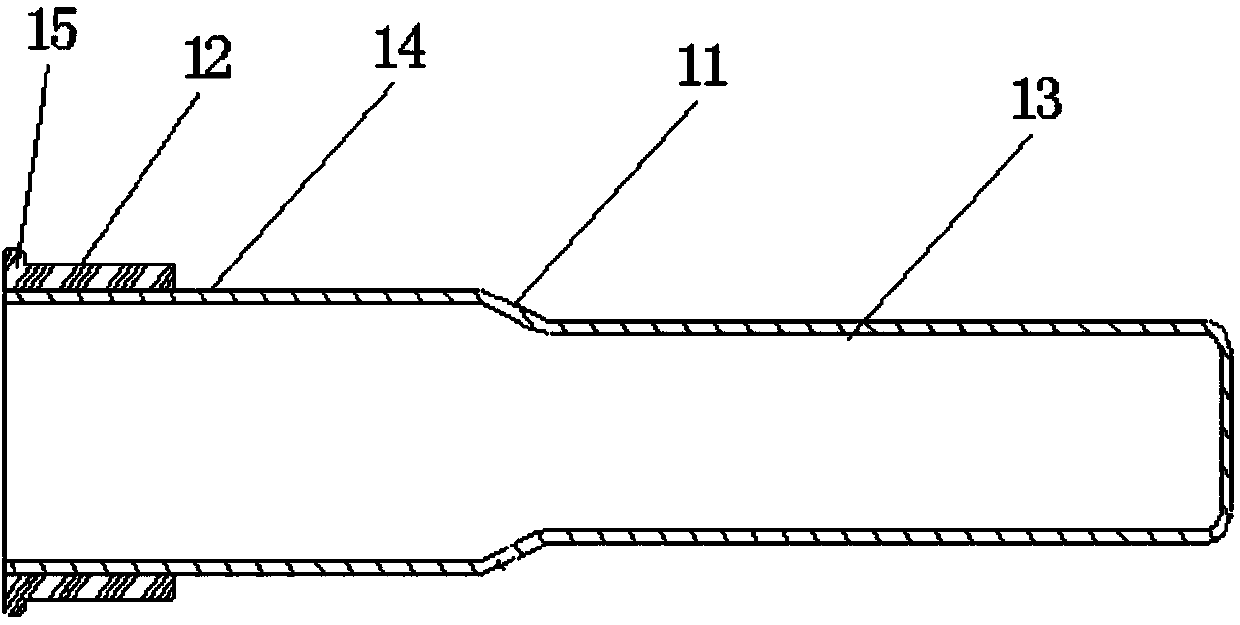

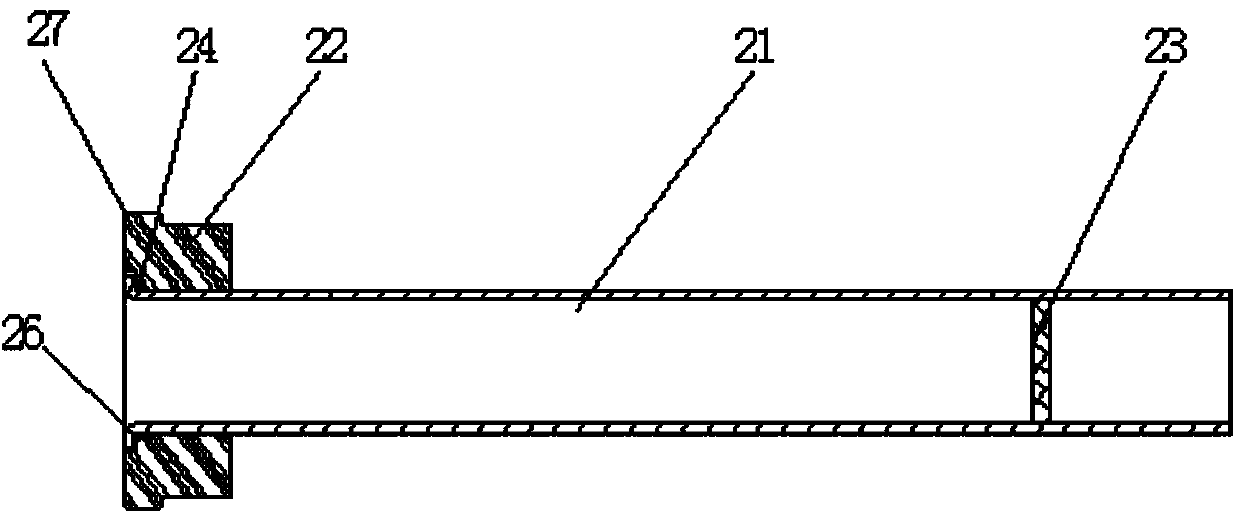

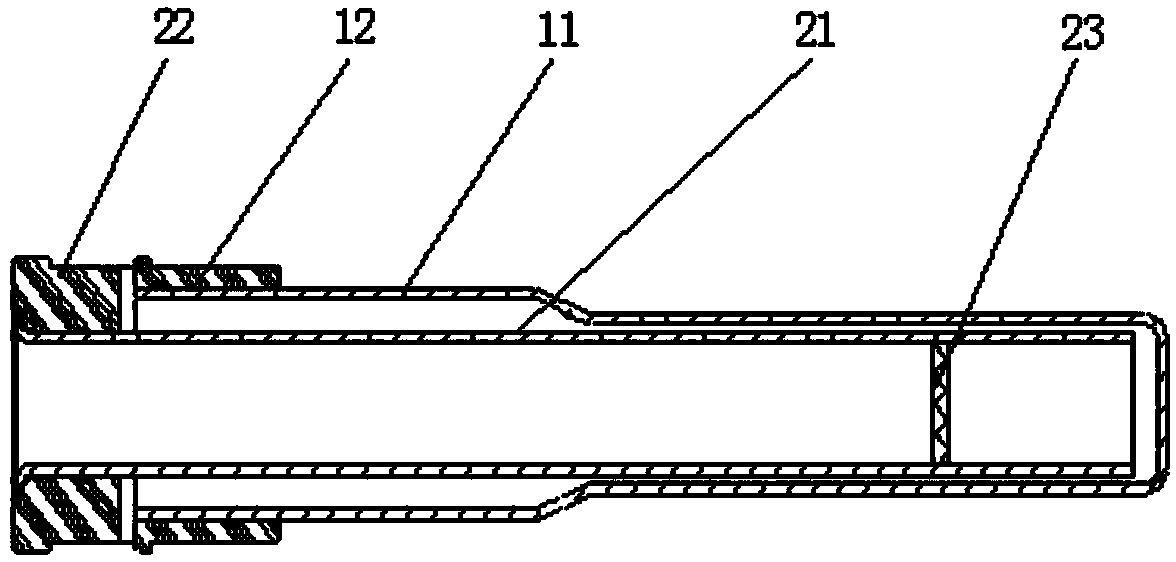

Test tube assembly for low-temperature quick ashing of organic matter sample

A technology for organic matter and samples, applied in the field of analysis and detection, can solve the problems of prolonged ashing time by muffle furnace heating temperature, high workload of operators, loss of volatile elements, etc., so as to reduce exogenous pollution and speed up ash The effect of short ashing time and ashing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Place the cleaned and dried test tubes on the test tube rack. Accurately weigh 0.5000g poplar leaf standard substance (GBW07604) from each inner tube 21 and evenly distribute it on the sand core 23 of the inner tube. Slowly move the entire test tube rack into the heating assembly, so that the area where the sample is placed is located in the middle of the heating assembly 33 . Connect the air circuit, feed high-purity oxygen with a gas flow rate of 100mL / min into the test tube, and control the oxygen flow rate in each test tube to be the same. Install a semiconductor cooling device at the thicker area of the outer tube to keep the cooling temperature at 4°C. The heating assembly was rapidly heated from room temperature to 200°C and kept for 20 minutes. After heating, take out the test tube rack and wait for it to cool down to room temperature naturally, remove the semiconductor refrigeration device and disconnect the air circuit, and place the test tube in the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com