Deep hypothermic heat regenerator adopting helium as heat regeneration medium and pulse tube refrigerator thereof

A technology of pulse tube refrigerators and regenerators, which is applied in the direction of refrigerators, superheaters, refrigeration components, etc., can solve the problems of a decrease in specific heat capacity and affect the cooling efficiency of regenerators and pulse tube refrigerators, so as to improve performance, The effect of efficient heat transfer and high volume specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

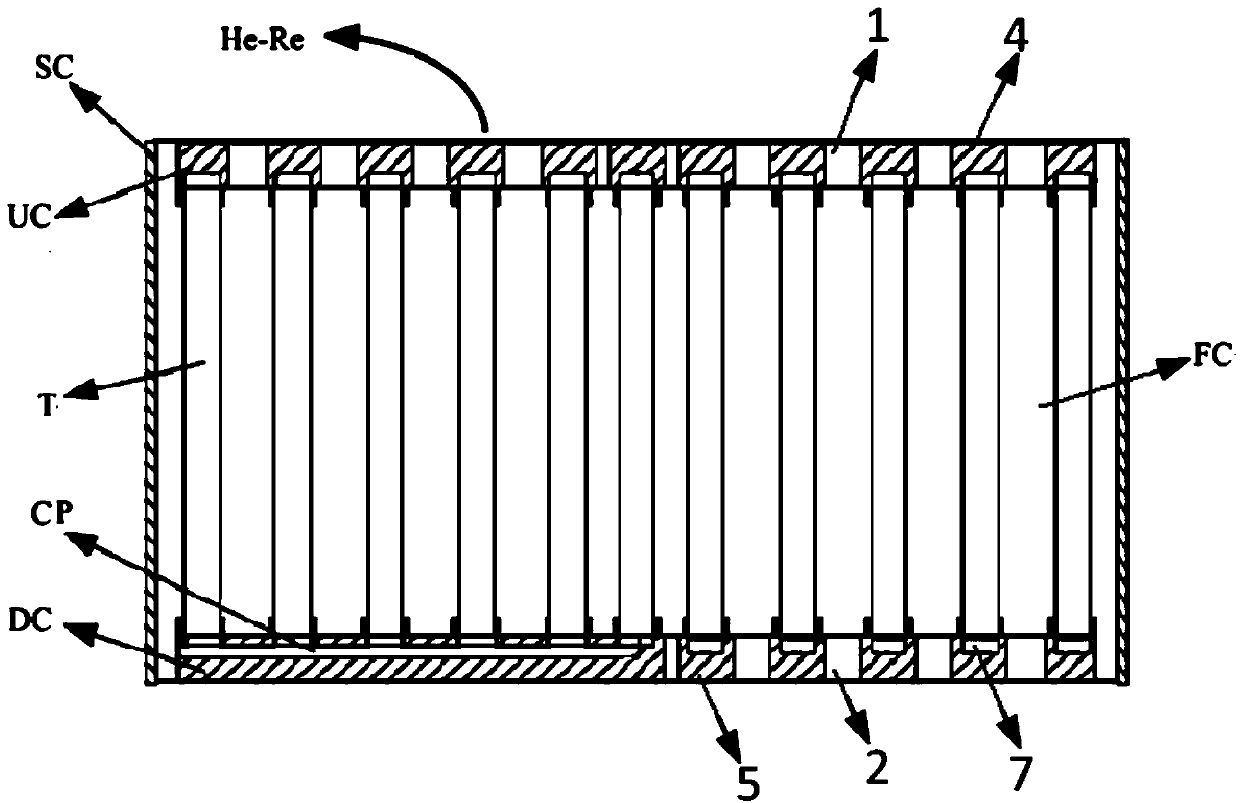

[0040] Such as Figure 1a with Figure 1b Shown: a deep low temperature regenerator He-Re using helium as the heat recovery medium includes: a tube shell SC with a hot end flow hole 1 and a cold end flow hole 2, and a return tube placed in the tube shell SC The hot filler and the regenerative filler have a gas flow channel FC connecting the hot end flow hole 1 and the cold end flow hole 2, and the regenerative filler is a sealed heat exchange structure filled with helium. The shell SC is a stainless steel tube.

[0041] The sealed heat exchange structure includes: an upper end cover UC, a lower end cover DC, and several groups of heat exchange tubes T fixed between the upper end cover UC and the lower end cover DC for filling helium. The heat exchange tube T is a copper tube. Each set of heat exchange tubes T is arranged in a ring shape; multiple sets of ring heat exchange tubes T are arranged concentrically. Between two adjacent sets of heat exchange tubes T is a gas flow...

Embodiment 2

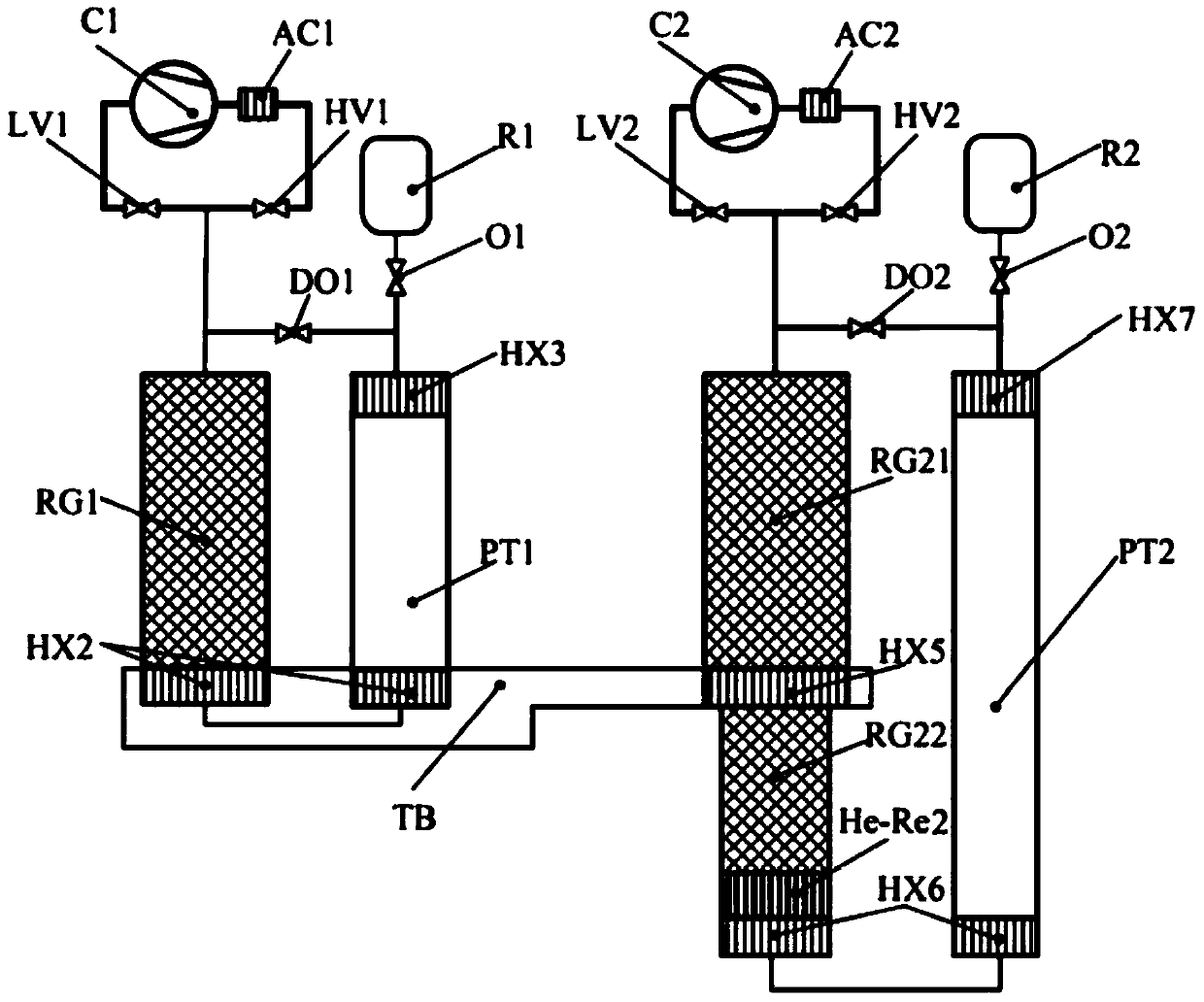

[0046] Such as figure 2 As shown, a two-stage low-frequency pulse tube refrigerator using helium as the heat recovery medium for a deep low-temperature regenerator includes: a first-stage compressor C1, a first-stage aftercooler AC1, a first-stage compressor Low-pressure control valve LV1, first-stage compressor high-pressure control valve HV1, first-stage regenerator RG1, first-stage cold-end heat exchanger HX2, first-stage pulse tube PT1, first-stage pulse tube hot-end heat exchanger The first-stage precooling pulse tube refrigerator unit composed of HX3, the first-stage two-way intake valve DO1, the first-stage orifice valve O1, and the first-stage gas storage R1, the thermal bridge TB, and the second-stage compressor C2 , The second-stage aftercooler AC2, the second-stage compressor low-pressure control valve LV2, the second-stage compressor high-pressure control valve HV2, the second-stage pre-cooling section regenerator RG21, the second-stage pre-cooling section regener...

Embodiment 3

[0056] Such as image 3 As shown, a high-frequency pulse tube refrigerator using helium as the heat recovery medium for a deep-low temperature regenerator includes a first-stage compressor C1, a first-stage regenerator hot-end heat exchanger HX1, a first-stage Regenerator RG1, first-stage cold-end heat exchanger HX2, first-stage pulse tube PT1, first-stage pulse tube hot-end heat exchanger HX3, first-stage inertial tube I1, first-stage gas storage R1 The first-stage pre-cooling pulse tube refrigerator unit, the first-stage thermal bridge TB1, consists of the second-stage compressor C2, the second-stage regenerator hot-end heat exchanger HX4, the second-stage pre-cooling section regenerator RG21, the second-stage regenerator Secondary pre-cooling section regenerator cold end heat exchanger HX5, second stage low temperature section regenerator RG23, second stage cold end heat exchanger HX6, second stage pulse tube PT2, second stage pulse tube hot end exchanger The second-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com