Biomass burner

A burner and biomass technology, which is applied in the field of biomass energy utilization equipment, can solve the problems that restrict the promotion and application of biomass energy and biomass burners, low combustion efficiency of biomass energy, and low energy utilization rate, etc., and achieve improvement Fuel combustion thermal efficiency and fuel utilization rate, fuel type unlimited, increase the effect of continuous burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

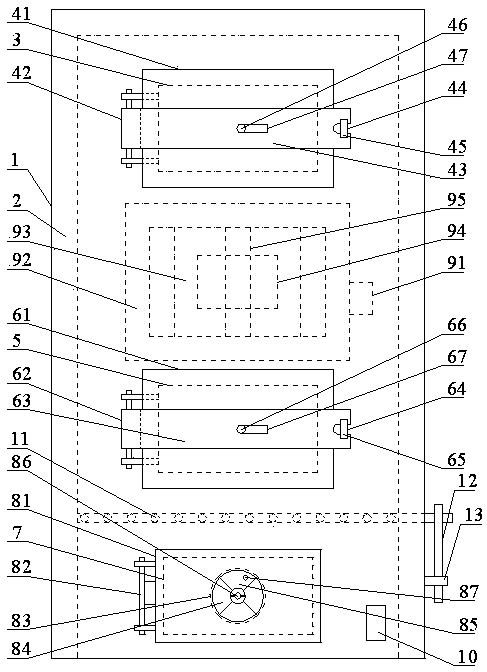

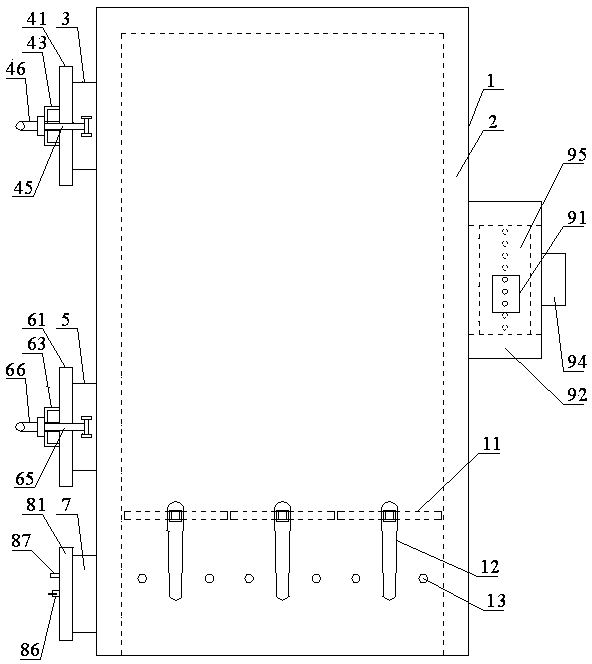

[0025] Such as Figure 1-Figure 4 The biomass burner shown includes a furnace body 1 and a refractory layer 2 inside the furnace body 1. The refractory layer 2 can effectively protect the furnace body 1 from burns, and can greatly extend the service life of the furnace body 1.

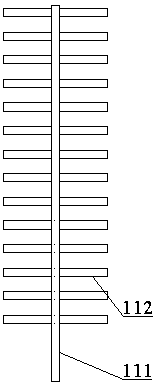

[0026] The front side of the furnace body 1 is provided with a filling port 3, a slag removal port 5 and a ash removal port 7 from top to bottom. The furnace body 1 is provided with a grate 11 between the slag removal port 5 and the ash removal port 7 , The number of grate 11 is three, and the three grate 11 are arranged side by side inside the furnace body 1. The grate 11 is composed of a grate shaft 111 and a grate shaft 111 symmetrically arranged on both sides of the grate 112; the outer end of the grate shaft 111 of the grate 11 is provided with a turning rocker 12, and the right side of the furnace body 1 is provided with a turning rocker. The limit posts 13 on both sides of the rod 12 operate the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com