Anti-spray rain cap

A rain cap and rain protection technology, applied in safety valves, engine components, balance valves, etc., can solve problems such as easy entry of rain and snow, freezing, and hidden dangers in production safety, and achieve the effect of reducing the scope of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

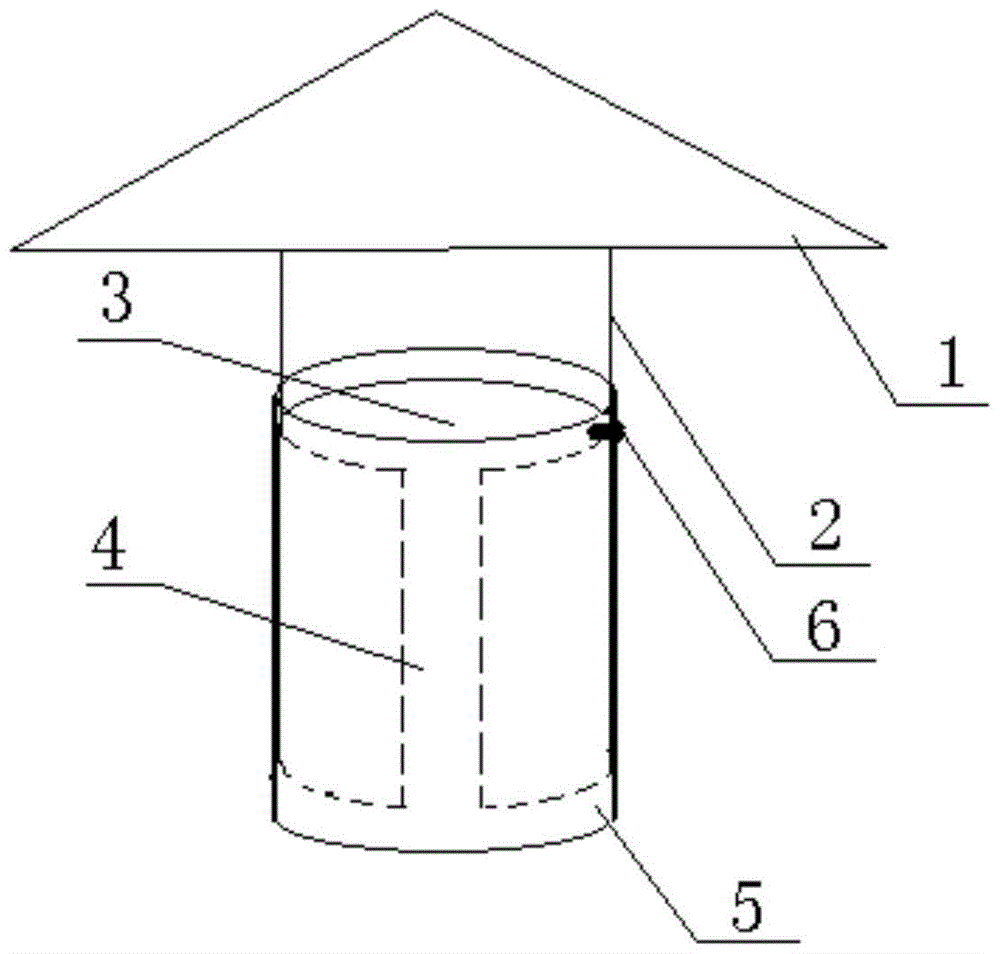

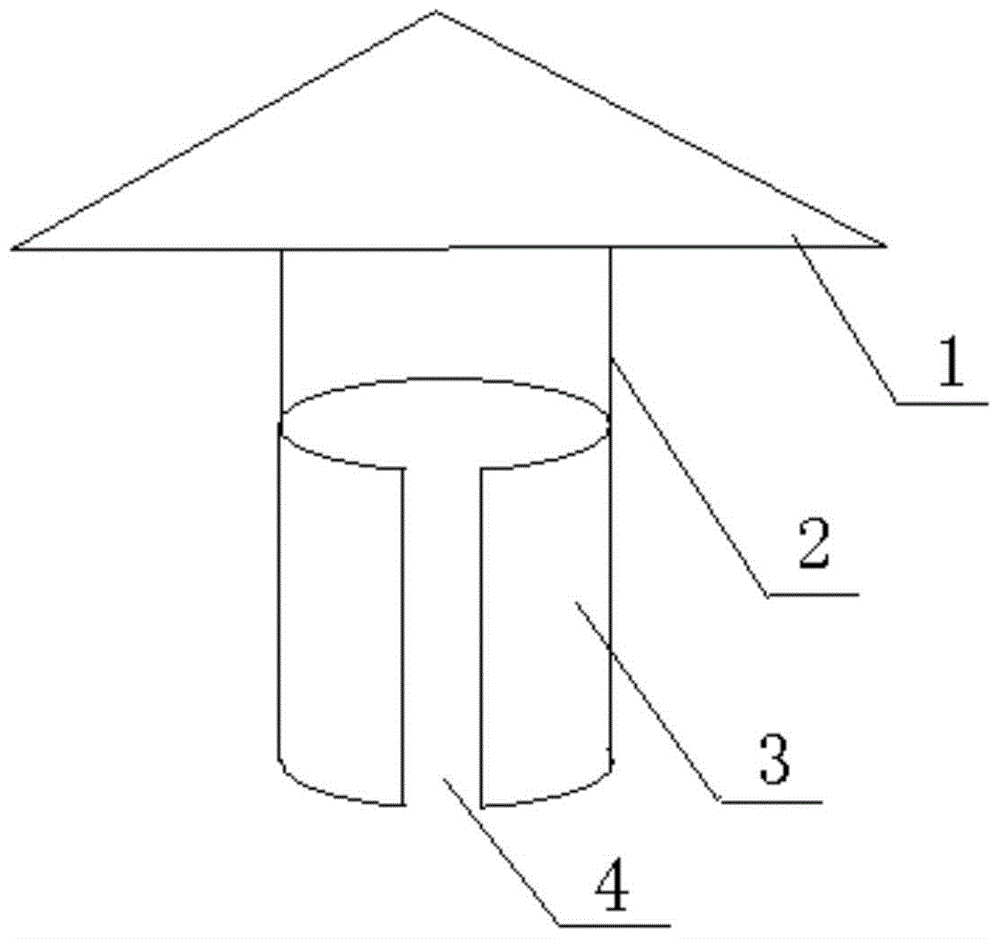

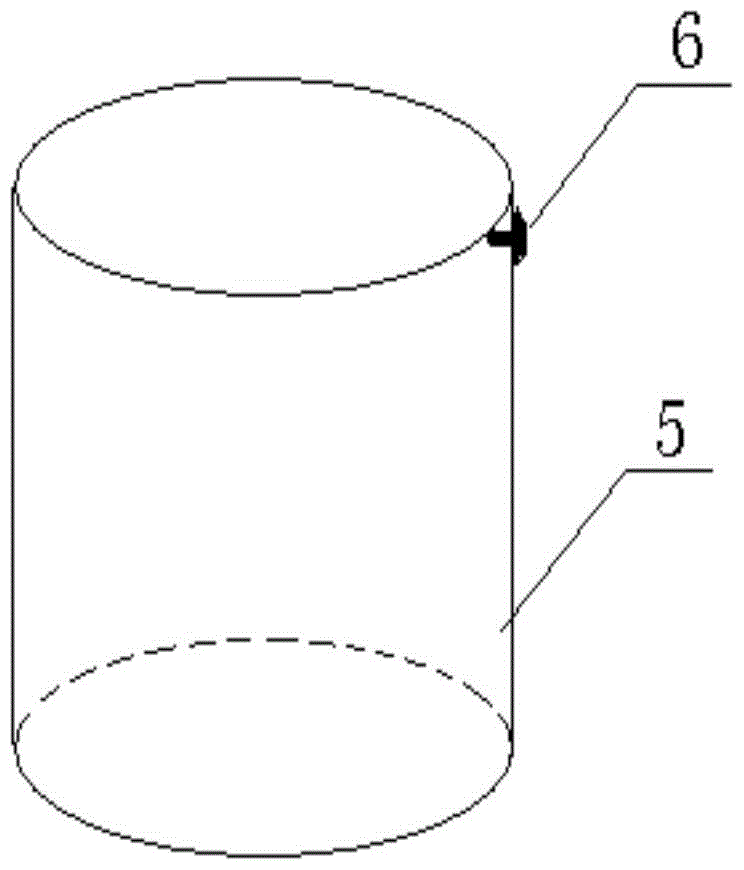

[0019] see figure 1 , an anti-spray rain cap provided by an embodiment of the present invention includes an umbrella cap 1 , a movable cylinder 3 connected to the umbrella cap 1 through a support frame 2 , and a fixed cylinder 5 sleeved on the movable cylinder 3 . see figure 2 The side wall of the movable tube 3 is provided with an opening 4, the support frame 2 is two rectangular steel plates, the lower ends of the steel plates of the support frame 2 are respectively welded on both sides of the mouth of the movable tube 3, and the upper ends of the steel plates of the support frame 2 are fixed on the umbrella Below the cap 1, the umbrella cap 1 is a conical top welded after the steel plate is rounded. see image 3 , the upper end of the wall of the fixed cylinder 5 is provided with a blowout preventer pin 6 , as an embodiment of the present invention, the blowout preventer pin 6 is a rivet riveted on the fixed cylinder 5 . The width of the opening 4 on the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com