Preparation method of low-cost zirconium dioxide toughened alumina ceramic granular powder

An alumina ceramic and zirconia technology, which is applied in the field of ceramic wear-resistant materials, can solve the problems of inconvenient mass production, complex technological process, environmental pollution, etc., and achieves easy automatic operation, high purity and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

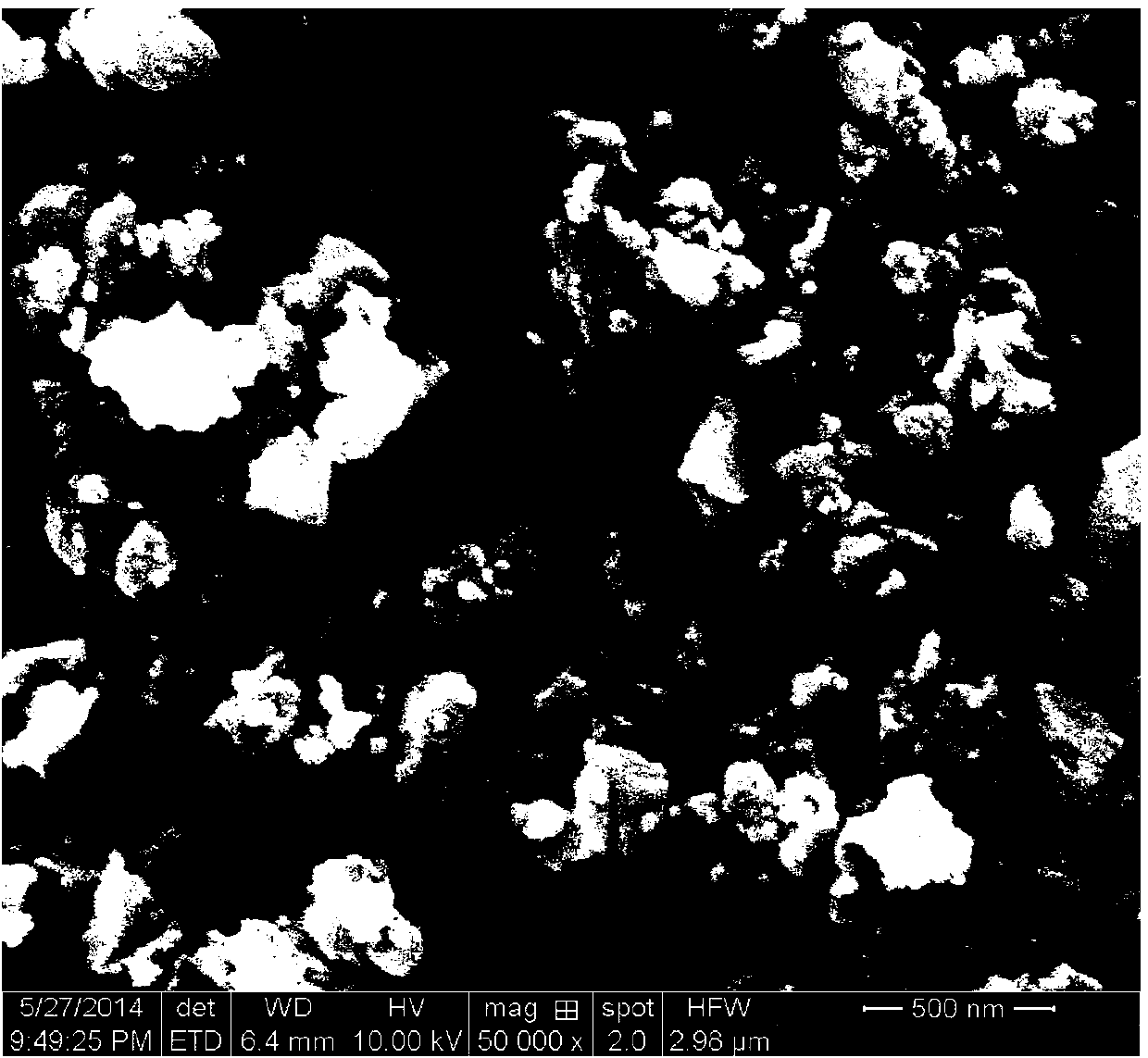

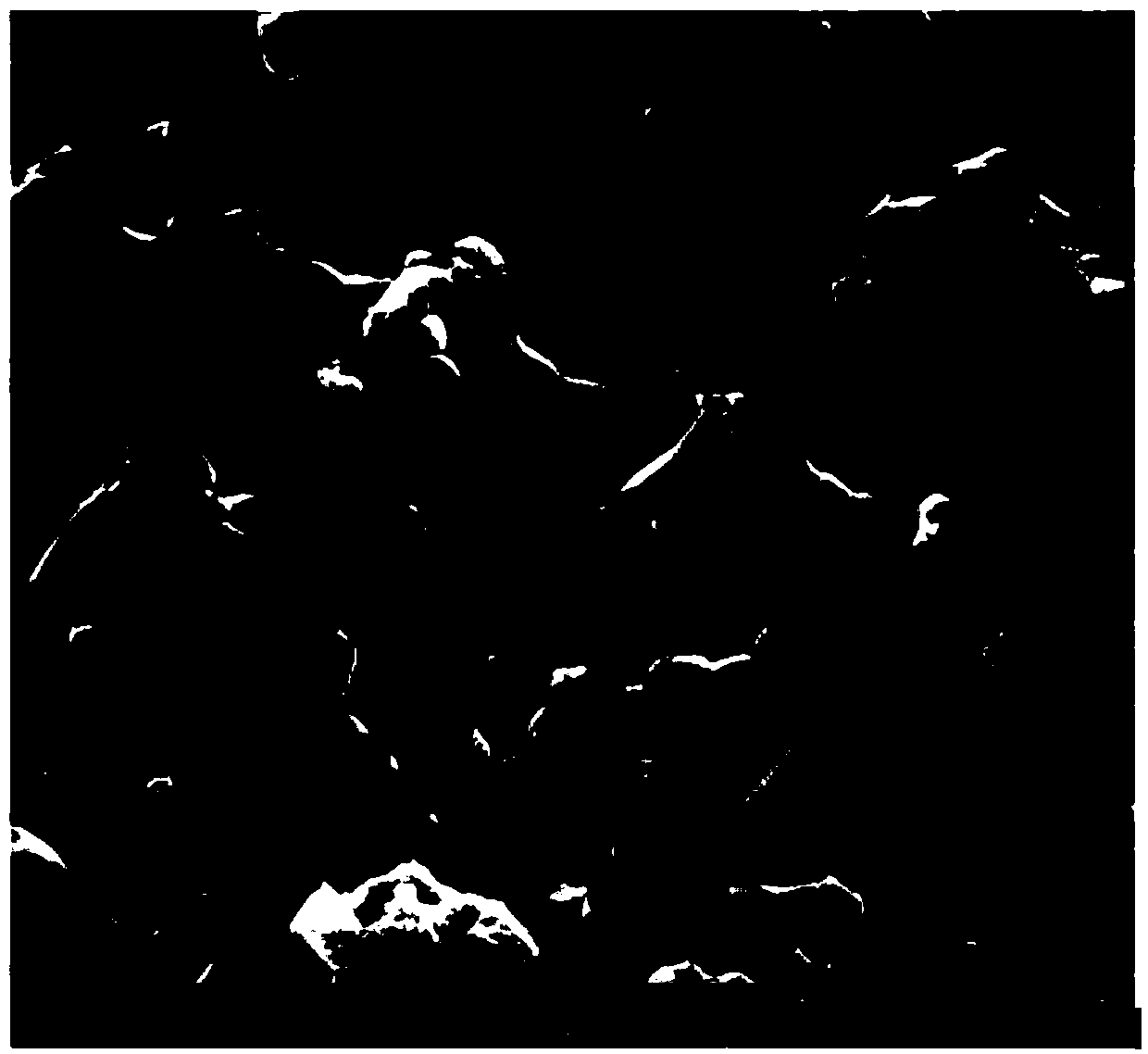

Image

Examples

Embodiment 1

[0043] The preparation method of the zirconia toughened alumina ceramic granulated powder of the present invention, the specific steps are as follows:

[0044] (1) With 3mol% yttrium oxide stabilized zirconia powder (D90 is less than 0.5 micron), microcrystalline alumina powder (D90 is less than 2.0 micron) and binding agent (the mixture of magnesium nitrate and magnesium carbonate, the mass ratio of the two is 1:1) as the main raw material, with deionized water as the dispersion medium, ball milling and mixing for 3 hours at room temperature to obtain a uniform mixed slurry; among them, 3mol% yttria-stabilized zirconia powder and microcrystalline alumina powder The mass ratio of the material is 30:70, the amount of the binder accounts for 1.0% of the total mass of the powder, and the mass ratio of the powder to deionized water is 1:1;

[0045] (2) Transfer the mixed slurry obtained in step (1) to a mixing tank, add a binder, and stir to obtain a uniform slurry after stirring ...

Embodiment 2

[0049] As in Example 1, the difference is that the mass ratio of 3mol% yttria-stabilized zirconia powder to microcrystalline alumina powder is 25:75, and the amount of binder accounts for 1.5% of the total mass of the powder. It is carboxymethyl cellulose, the amount of which accounts for 0.2% of the total mass of the powder, ball milling for 2 hours, stirring for 2 hours, the temperature of the air inlet of the spray granulation tower is 300°C, and the temperature of the air outlet is 80°C; The measured flexural strength of the final ceramic is 810.31MPa, and the fracture toughness is 8.96MPa m 1 / 2 .

Embodiment 3

[0051] As in Example 1, the difference is that the mass ratio of 3mol% yttria-stabilized zirconia powder to microcrystalline alumina powder is 20:80, and the amount of binder accounts for 0.75% of the total mass of the powder. (The mass ratio of polyvinyl alcohol and carboxymethyl cellulose is 1:1). The addition amount accounts for 0.1% of the total mass of the powder, the ball mill is mixed for 5 hours, stirred for 1 hour, and the air inlet temperature of the spray granulation tower is 300 ℃, the air outlet temperature is 90℃; the flexural strength of the fired ceramics is 807.65MPa, and the fracture toughness is 7.87MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com