Ceramic plate for cooking bench, and preparation and application method thereof

A ceramic plate and stove technology, applied in the field of building materials, can solve problems such as being easily affected by temperature changes and water vapor, affecting the home environment, and accumulating large oil pollution, etc., to achieve enhanced microscopic strain performance, simple splicing methods, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

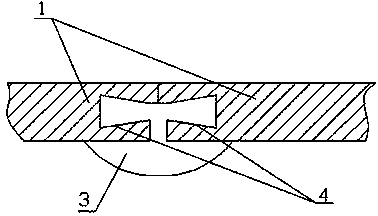

[0071] A ceramic plate for a cooktop is composed of a green body and a glaze; slots for splicing are provided on both sides of the green body.

[0072] The preparation method of the ceramic plate for the cooktop comprises the following steps:

[0073] 1) After adding water to 2 kg of kaolin to make a slurry, slowly add 0.5 kg of epoxy resin toughening emulsion containing modified bamboo fiber, stir thoroughly for 0.5 h, dry, calcined at 200°C for 0.5 h, crush, and pass through a 200-mesh sieve Obtain modified kaolin;

[0074] 2) Mix the modified kaolin in step 1) with 1 kg of phosphogypsum, 0.8 kg of quartz, 0.5 kg of feldspar, and 0.3 kg of lime, and then ball mill to obtain a ceramic slurry;

[0075] 3) Dry or dry the ceramic slurry in step 2) and press it into a ceramic slab body;

[0076] 4) Dry the ceramic slab body in step 3) in a drying kiln until the water content is 3%, raise the temperature of the green body to 1000°C at 10°C / min, keep it warm for 2 hours, and then...

Embodiment 2

[0092] A ceramic plate for a cooktop is composed of a green body and a glaze; slots for splicing are provided on both sides of the green body.

[0093] The preparation method of the ceramic plate for the cooktop comprises the following steps:

[0094] 1) Add water to 3 kg of kaolin to make a slurry, slowly add 1 kg of epoxy resin toughening emulsion containing modified bamboo fiber, stir thoroughly for 1 hour, dry, calcined at 250°C for 0.5 hour, pulverize, and pass through a 300-mesh sieve to obtain Modified kaolin;

[0095] 2) Mix the modified kaolin in step 1) with 1.5 kg of phosphogypsum, 1.5 kg of quartz, 0.8 kg of feldspar, and 0.5 kg of lime, and then ball mill to obtain a ceramic slurry;

[0096] 3) Dry or dry the ceramic slurry in step 2) and press it into a ceramic slab body;

[0097] 4) Dry the ceramic slab body in step 3) in a drying kiln until the water content is 5%, raise the temperature of the green body to 1200°C at 12°C / min, keep it warm for 1 hour, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com