Oil-water separation screen membrane with lead ion responsiveness and preparation method of membrane

A technology for oil-water separation ophthalmic membrane and lead ions, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., to achieve the effects of simplifying sewage treatment devices, improving stability, and enhancing the performance of separation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

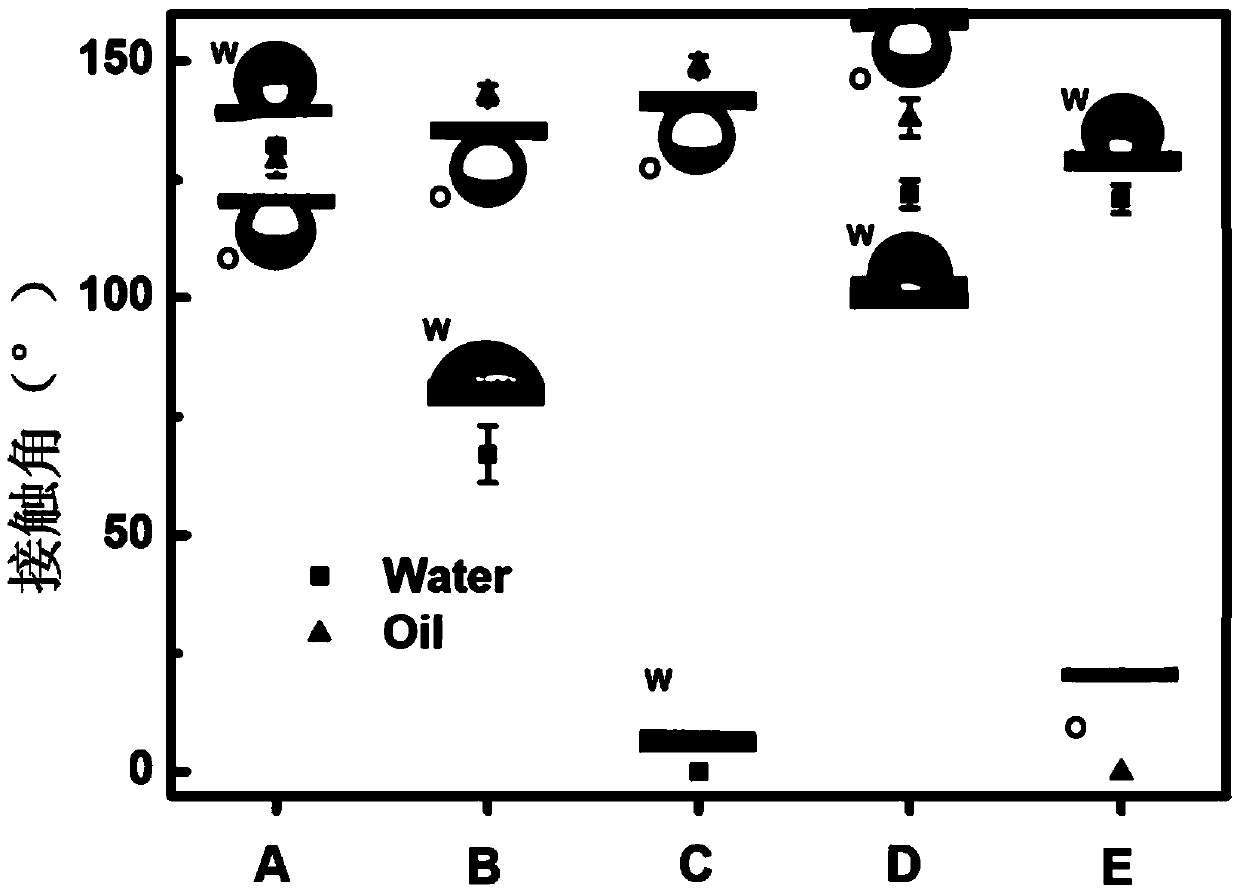

[0043] Example 1, preparation of responsive oil-water separation omentum of hydrophilic and oleophobic

[0044] (1) Soak the 1000-mesh stainless steel mesh in a mixed solution of acetone and ethanol with a volume ratio of 1:1 for 30 minutes, and then dry it with hot air after cleaning;

[0045] (2) At room temperature, add 60mL of water and 0.24g of trishydroxymethylaminomethane to a 100mL beaker, stir evenly, drop hydrochloric acid solution to adjust the pH to 8.5, and obtain a mixed buffer solution (TRIS-HCl buffer solution );

[0046] (3) Add 0.12 g of dopamine hydrochloride to the mixed buffer solution obtained in step (2) to obtain a mixed solution. In the mixed solution, the mass percentage of dopamine hydrochloride is 0.20%, and the mass percentage of trishydroxymethylaminomethane is 0.40%;

[0047] (4) Immerse the dried stainless steel mesh in step (1) in the mixed solution obtained in step (3), place it for 72 hours, take it out and rinse it with deionized water, and ...

Embodiment 2

[0056] Example 2, preparation of responsive oil-water separation omentum of hydrophilic and oleophobic

[0057] (1) Immerse the 400-mesh copper mesh in a mixed solution of acetone and ethanol with a volume ratio of 1:1 and ultrasonicate for 30 minutes, and then dry it with hot air after cleaning;

[0058] (2) At room temperature, add 60 mL of water and 0.24 g of Tris to a 100 mL beaker, stir evenly, drop in hydrochloric acid solution to adjust the pH to 8.5, and obtain a mixed buffer solution;

[0059] (3) Add 0.36 g of dopamine hydrochloride to the mixed buffer solution obtained in step (2) to obtain a mixed solution. In the mixed solution, the mass percentage of dopamine hydrochloride is 0.60%, and the mass percentage of trishydroxymethylaminomethane is 0.40%;

[0060] (4) Immerse the dried copper mesh in step (1) in the mixed solution obtained in step (3), place it for 48 hours, take it out and rinse it with deionized water, and let it dry naturally;

[0061] (5) At room ...

Embodiment 3

[0067] Example 3, preparation of responsive oil-water separation omentum of hydrophilic and oleophobic

[0068] (1) Soak the 1000-mesh aluminum alloy mesh in a mixed solution of acetone and ethanol with a volume ratio of 1:1 and ultrasonically clean it for 30 minutes, and dry it with hot air after cleaning;

[0069] (2) At room temperature, add 60 mL of water and 0.24 g of Tris to a 100 mL beaker, stir evenly, drop in hydrochloric acid solution to adjust the pH to 8.5, and obtain a mixed buffer solution;

[0070] (3) Add 0.36 g of dopamine hydrochloride to the mixed buffer solution obtained in step (2) to obtain a mixed solution. In the mixed solution, the mass percentage of dopamine hydrochloride is 0.60%, and the mass percentage of trishydroxymethylaminomethane is 0.40%;

[0071] (4) Immerse the aluminum alloy mesh dried in step (1) in the mixed solution obtained in step (3), place it for 72 hours, take it out and rinse it with deionized water, and dry it naturally;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com