Steak processing method

A production method and technology of steak, applied in the field of preparation or processing of meat products, can solve problems such as unsatisfactory tenderization effect, achieve the effects of easy chewing and digestion, improvement of water holding capacity, and nutritional supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

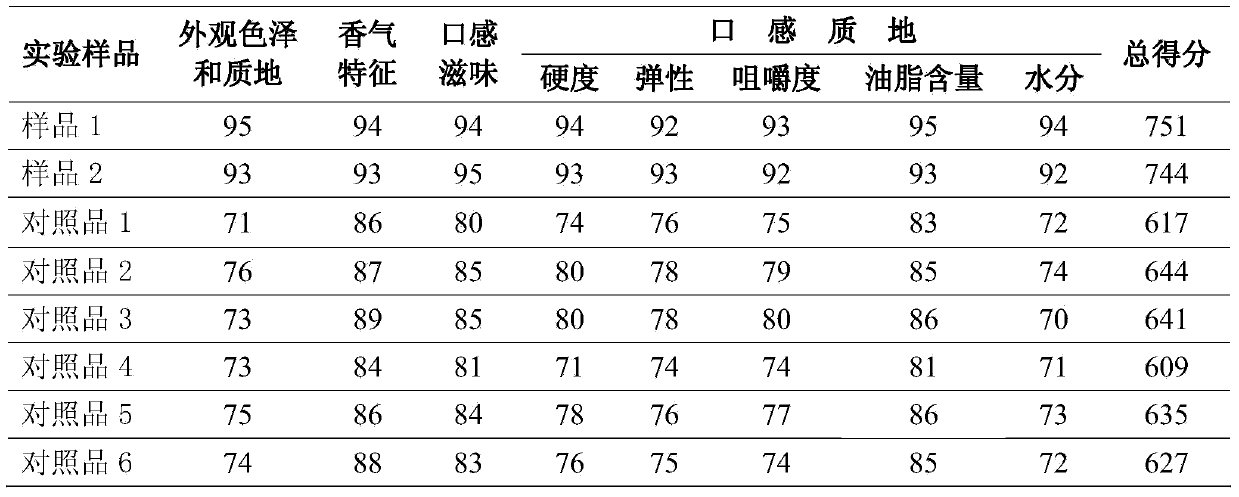

Examples

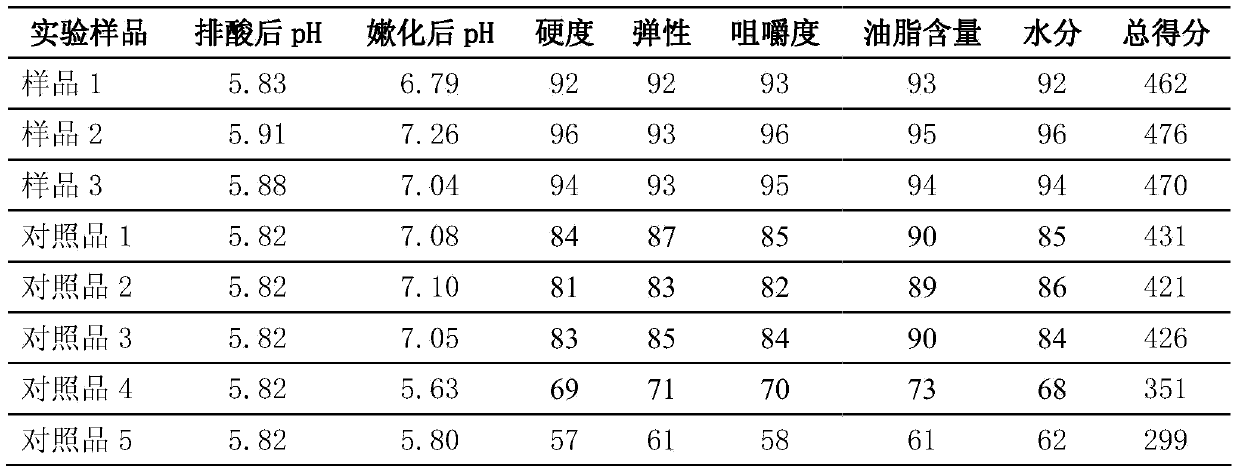

Embodiment 1

[0029] A kind of preparation method of steak according to the present invention, this method is made up of the following steps:

[0030] 1. Cooling and deacidification: After the slaughtered beef cattle pass the quarantine inspection, the carcass is sent to the deacidification room for pre-cooling within 30 minutes, so that the cattle carcass is cooled to 0-4 ° C, and the relative humidity is 90%, and the wind speed is 1.5 m / Under the condition of 20 seconds, let it stand for 20 hours; then let it stand for 10 hours under the condition of temperature 0-4°C and relative humidity 80%-98%, so that the carcass muscle becomes soft and completes the process of deacidification; according to "GB / T 9695.5- According to the 2008 / ISO 2917:1999 Meat and Meat Products pH Determination, the pH value of the beef after deacidification was measured by using the German Meters PH-STAR ordinary carcass meat pH value direct tester to measure 5.83.

[0031] 2. Cutting and cleaning: Deboning the c...

Embodiment 2

[0039] A kind of preparation method of steak described in the present embodiment, this method is made up of the following steps:

[0040] 1. Cooling and deacidification: same as in Example 1, the pH value of the beef after deacidification is measured to be 5.91.

[0041] 2. Separation and cleaning: the same as in Example 1.

[0042] 3. Tumbling and marinating: Pour the sliced steak into the tumbler, add 5% of the tenderizer by weight of the steak, roll and knead for 30 minutes at 33 rpm, and then add 8% of the weight of the steak to marinate The preparation was rolled and kneaded for another 30 minutes, and then left to stand for 45 minutes; the pH value of the tenderized steak was measured to be 7.26.

[0043] In step 3, the composition ratio and preparation method of the tenderizer are the same as in Example 1;

[0044] The pickling agent is composed of the following raw materials in parts by weight: 15 salt, 10 monosodium glutamate, 10 soy sauce, 5 beef powder, 13 black...

Embodiment 3

[0050] A kind of preparation method of steak described in the present embodiment, this method is made up of the following steps:

[0051] 1. Cooling and deacidification: same as in Example 1, the pH value of the beef after deacidification is measured to be 5.88.

[0052] 2. Separation and cleaning: the same as in Example 1.

[0053] 3. Tumbling and marinating: Pour the cut sliced steak into the tumbler, add 4% of the tenderizer by weight of the steak, roll and knead for 30 minutes at 30 rpm, and then add 9% of the weight of the steak to marinate The preparation was rolled and kneaded for another 30 minutes, and then left to stand for 30 minutes; the pH value of the tenderized steak was measured to be 7.04; wherein,

[0054] The tenderizer is composed of the following raw materials in parts by weight: papaya puree 10, pineapple puree 4, glucose 3, sodium bicarbonate 3; its preparation method is the same as in Example 1;

[0055] The pickling agent is composed of the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com