Seasoning wine and preparation method thereof

A technology for seasoning wine and spice extract, which is applied in the preparation of alcoholic beverages, food preparation, ingredients of alcoholic foods, etc., can solve problems such as affecting product quality, large amount of spices used, hidden dangers of food safety, etc., and achieve stable product quality. , It is not easy for bacteria to exceed the standard, and the effect of avoiding alcohol volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

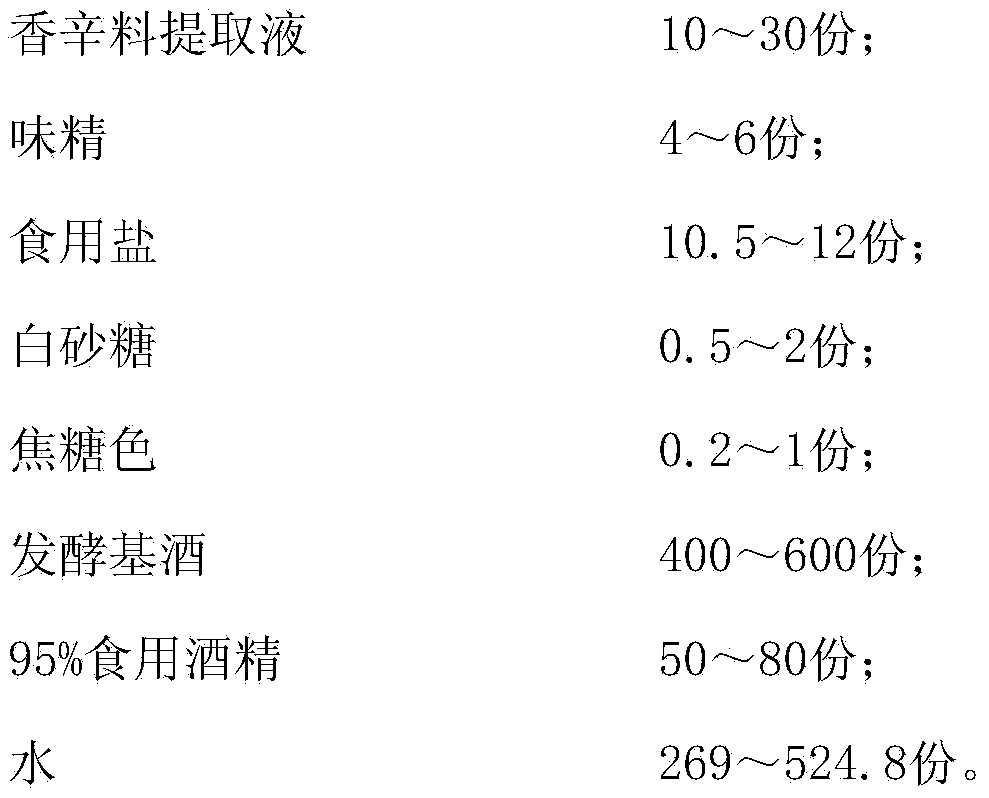

[0031] A seasoning wine, characterized in that it contains the following components: in parts by weight,

[0032]

[0033] The spice extract is composed of star anise, sanna, cinnamon, clove, nutmeg, cardamom, grass fruit, fragrant fruit, amomum, black pepper, cumin and water in a weight ratio: 0.1:0.05:0.025:0.2:0.1: 0.05: 0.05: 0.05: 0.1: 0.05: 0.1: 50;

[0034] The alcohol content of the fermented base wine is 10% by volume at a temperature of 20°C.

[0035] The preparation method of the above-mentioned seasoning wine includes the following steps:

[0036] A. Preparation of spice extract:

[0037] Use a grinder to separate by weight 0.1 part of star anise, 0.05 part of San Nai, 0.025 part of cinnamon, 0.2 part of clove, 0.1 part of nutmeg, 0.05 part of cardamom, 0.05 part of grass fruit, 0.05 part of vanilla, 0.1 part of Amomum, 0.05 part by weight. 1 part of black pepper and 0.1 part of fennel spice raw materials are crushed to a size of 200 mesh, then 50 parts by weight of water ...

Embodiment 2

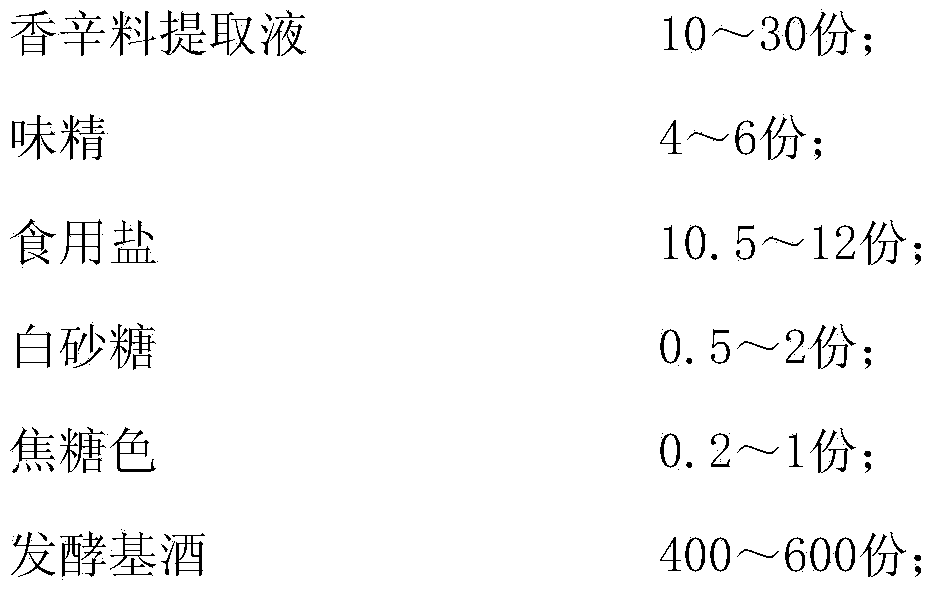

[0045] A seasoning wine, characterized in that it contains the following components: in parts by weight,

[0046]

[0047] The spice extract is composed of star anise, sanna, cinnamon, clove, nutmeg, cardamom, grass fruit, fragrant fruit, amomum, black pepper, cumin and water in a weight ratio: 0.15:0.1:0.05:0.25:0.15: 0.1: 0.1: 0.1: 0.15: 0.1: 0.15: 50;

[0048] The alcohol content of the fermentation base wine is 9% by volume at a temperature of 20°C.

[0049] The preparation method of the above-mentioned seasoning wine includes the following steps:

[0050] A. Preparation of spice extract:

[0051] Use a grinder to separate 0.15 parts by weight of star anise, 0.1 parts of sanna, 0.05 parts of cinnamon, 0.25 parts of cloves, 0.15 parts of nutmeg, 0.1 parts of cardamom, 0.1 parts of grass fruit, 0.1 parts of fennel, 0.15 parts of Amomum, 0.1 parts by weight. 1 part of black pepper and 0.15 part of cumin spice raw material are crushed to a size of 80 mesh, then 50 parts by weight of w...

Embodiment 3

[0059] A seasoning wine, characterized in that it contains the following components: in parts by weight,

[0060]

[0061] The spice extract is composed of star anise, sanna, cinnamon, clove, nutmeg, cardamom, grass fruit, fragrant fruit, amomum, black pepper, cumin and water in a weight ratio: 0.12:0.07:0.04:0.22:0.12: 0.07: 0.07: 0.07: 0.12: 0.07: 0.12: 50;

[0062] The alcohol content of the fermentation base wine is 12% by volume at a temperature of 20°C.

[0063] The preparation method of the above seasoning wine includes the following steps:

[0064] A. Preparation of spice extract:

[0065] Using a pulverizer, respectively, in parts by weight, 0.12 parts star anise, 0.07 parts San Nai, 0.04 parts cinnamon, 0.22 parts cloves, 0.12 parts nutmeg, 0.07 parts cardamom, 0.07 parts grass fruit, 0.07 parts vanilla, 0.12 parts Amomum, 0.07 parts 1 part of black pepper and 0.12 part of fennel spice raw materials are crushed to a size of 140 mesh, then 50 parts by weight of water are adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com