Method for obtaining organic fertilizer and bioprotein simultaneously by biologically treating inapplicable fresh tobacco leaves with chrysomya megacephala larva

A technology of bio-organic fertilizer and golden fly, applied in application, animal feed, animal feed, etc., can solve the problems of energy consumption, high nicotine content, etc., and achieve the effects of cost reduction, good growth effect, and biological treatment effect promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

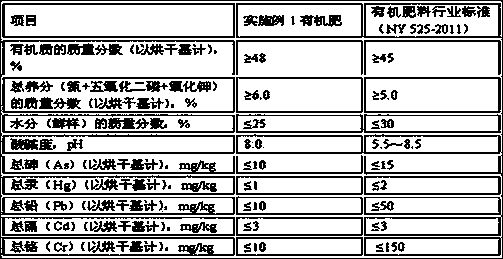

Embodiment 1

[0043] S1. Use a grass cutter to chop unsuitable fresh tobacco leaves into fragments with a particle size of 2 to 3 cm, add appropriate amount of auxiliary materials, stir evenly, and prepare compost; the formula of compost mentioned in S1 is shown in Table 1:

[0044] Table 1

[0045] raw material name Mass percentage (%) Not suitable for fresh tobacco leaves (fragments) 60 bran 25 bran powder 5 sawdust 5 fish meal 5

[0046] S2. The compost is poured into the container, the compost is 6cm thick, and an appropriate amount of Chrysocephala macrocephala ovum is inserted on the surface of the compost, and the egg density is: 0.2g Chrysophora macrocephala ovum / kg compost;

[0047] S3. The eggs of Chrysocephala cerevisiae hatched into larvae on the 2nd day, and began to decompose and transform the compost. During the transformation process, the humidity of the compost was maintained at about 60%. On the 4th day, a larger container was...

Embodiment 2

[0054] S1. Use a grass cutter to chop unsuitable fresh tobacco leaves into fragments with a particle size of 2 to 3 cm, add appropriate amount of auxiliary materials, stir evenly, and prepare compost; the formula of compost described in S1 is shown in Table 3:

[0055] table 3

[0056] raw material name Mass percentage (%) Not suitable for fresh tobacco leaves (fragments) 75 bran 10 bran powder 5 sawdust 5 fish meal 5

[0057] S2. Pour the culture material into the container, the culture material is 8cm thick, and insert an appropriate amount of Chrysophora macrocephala ovum on the surface of the culture material, and the density of the eggs is: 1.0g Chrysocephala macrocephala ovum / kg culture material;

[0058] S3. The eggs of Chrysocephala cerevisiae hatched into larvae on the 2nd day, and began to decompose and transform the compost. During the transformation process, the humidity of the compost was maintained at about 60%. On t...

Embodiment 3

[0063] S1. Use a grass cutter to chop unsuitable fresh tobacco leaves into fragments with a particle size of 2 to 3 cm, add appropriate amount of auxiliary materials, stir evenly, and prepare compost; the formula of compost described in S1 is shown in Table 5:

[0064] table 5

[0065] raw material name Mass percentage (%) Not suitable for fresh tobacco leaves (fragments) 85 bran 0 bran powder 5 sawdust 5 fish meal 5

[0066] S2. Pour the culture material into the container, the culture material is 10cm thick, and insert an appropriate amount of Chrysophora macrocephala ovum on the surface of the culture material, and the density of the eggs is: 2.0g Chrysocephala macrocephala eggs / kg culture material;

[0067] S3. The eggs of Chrysocephala cerevisiae hatched into larvae on the 2nd day, and began to decompose and transform the compost. During the transformation process, the humidity of the compost was maintained at about 60%. On t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com