Organic light emitting device and manufacturing method thereof

An electroluminescence device and luminescence technology, which is applied in the manufacture of organic semiconductor devices, electric solid state devices, semiconductor/solid state devices, etc., can solve the problems of small driving current, low device life, and large current for driving light emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

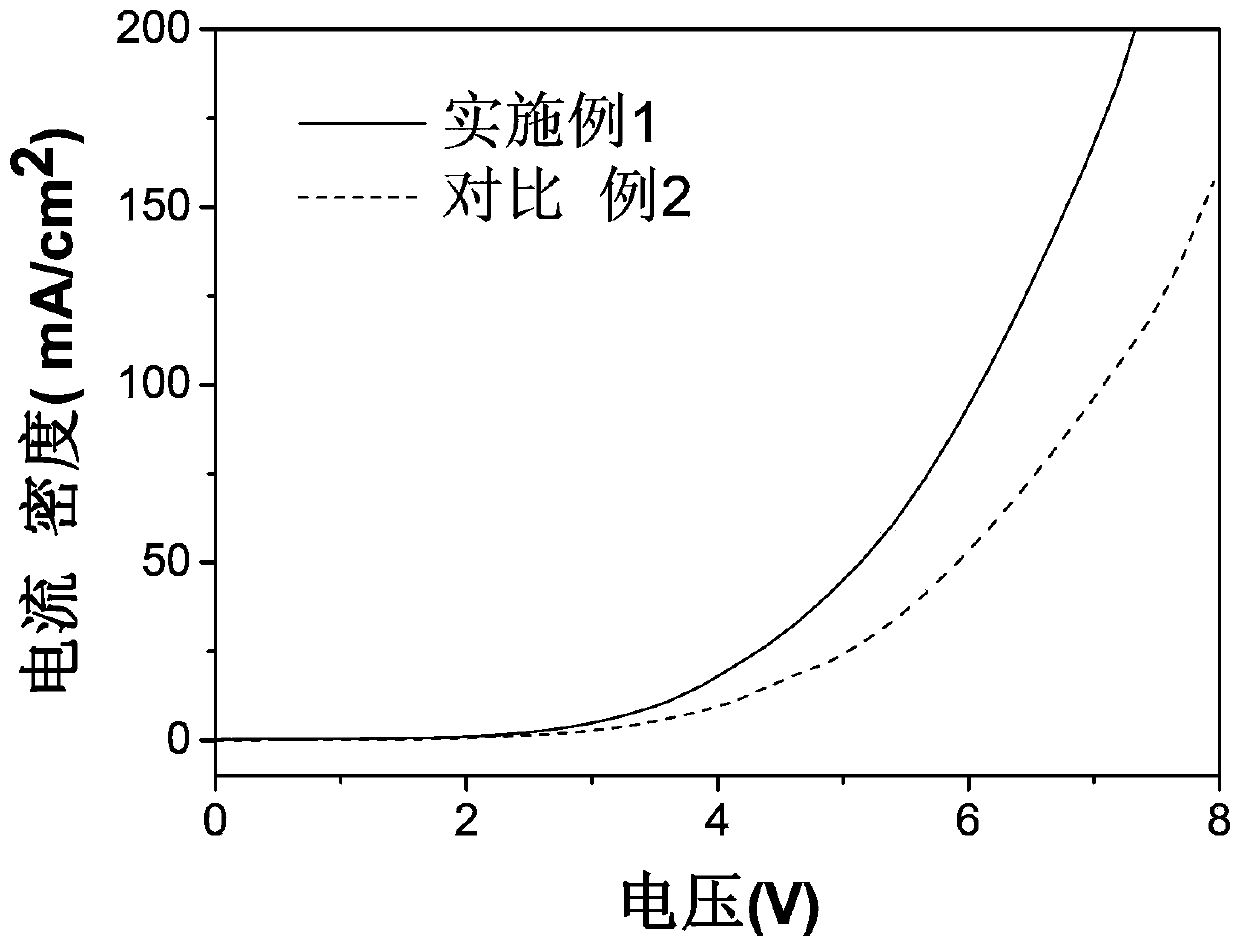

Embodiment 1

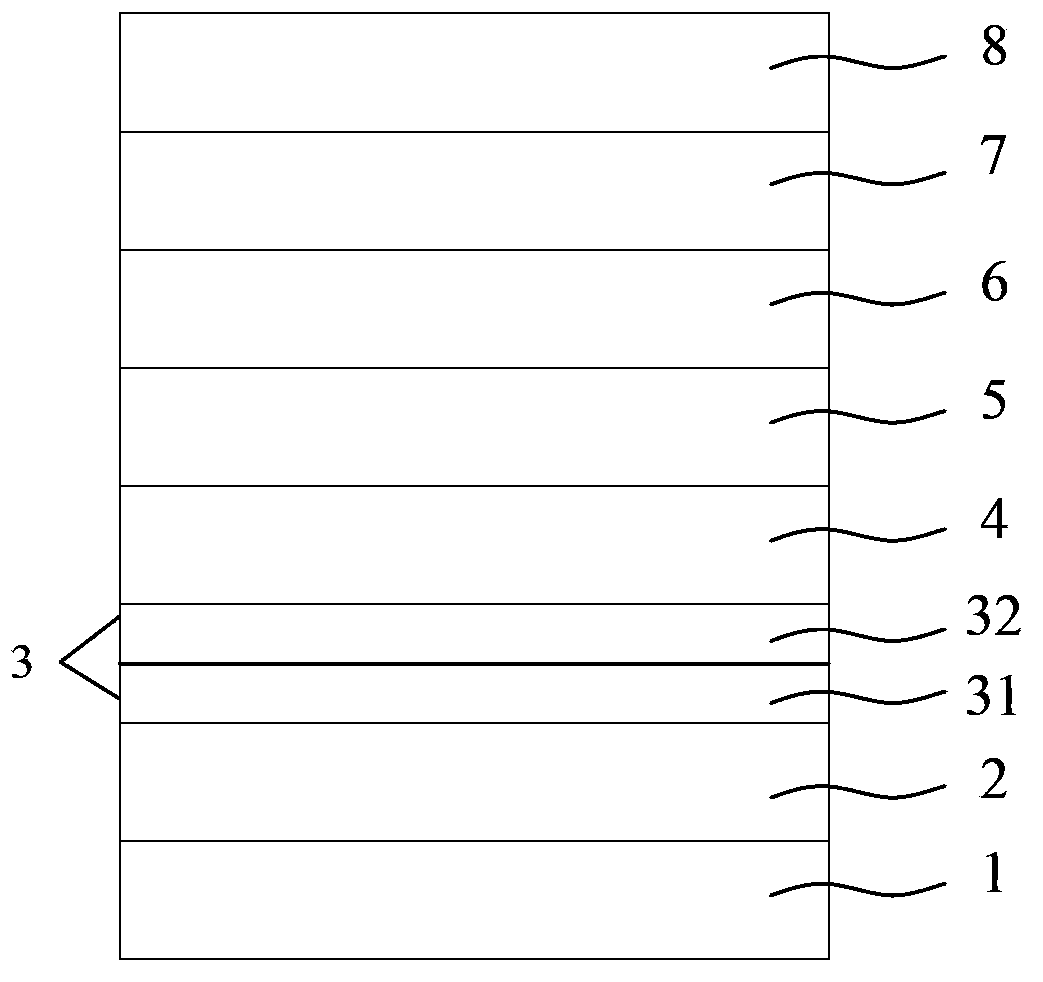

[0048] A method for preparing an organic electroluminescent device, comprising the following steps:

[0049] (1) After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol overnight. On the glass substrate 1, the anode 2 is prepared by magnetron sputtering to obtain the anode substrate. The material of the anode 2 is ITO, the thickness is 70nm, the sputtering rate is 0.2nm / s, and the pressure during magnetron sputtering is 1×10 -5 ;

[0050] (2) Put the anode substrate into the vapor deposition chamber, feed hydrogen to maintain the pressure of the vapor deposition chamber at 10Pa, then raise the temperature of the vapor deposition chamber to 600°C, and then feed methane to maintain the pressure of the vapor deposition chamber at 10Pa , on the anode substrate, a graphene film is prepared by vapor deposition, and after the reaction is completed, a graphene film with a thickness of 4nm is obtained;

[0051] Transfer the graphene film into the pl...

Embodiment 2

[0063] A method for preparing an organic electroluminescent device, comprising the following steps:

[0064] (1) After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for one night. The anode was prepared by magnetron sputtering on the glass substrate, and the anode substrate was obtained. The material of the anode was IZO, the thickness was 200nm, the sputtering rate was 2nm / s, and the pressure during magnetron sputtering was 1×10 -3 ;

[0065] (2) Put the anode substrate into the vapor deposition chamber, feed hydrogen to maintain the pressure of the vapor deposition chamber at 1000Pa, then raise the temperature of the vapor deposition chamber to 1000°C, and then feed ethane to maintain the pressure of the vapor deposition chamber at 1000Pa, prepare a graphene film by vapor deposition on the anode substrate; after the reaction is completed, a graphene film with a thickness of 10nm is obtained;

[0066] Graphene thin film is transferred ...

Embodiment 3

[0078] A method for preparing an organic electroluminescent device, comprising the following steps:

[0079] (1) After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol overnight. The anode was prepared by magnetron sputtering on the glass substrate, and the anode substrate was obtained. The anode material was AZO, the thickness was 80nm, the sputtering rate was 1nm / s, and the pressure during magnetron sputtering was 1×10 -4 ;

[0080] (2) Put the anode glass substrate into the vapor deposition chamber, feed hydrogen to maintain the pressure of the vapor deposition chamber at 500 Pa, then raise the temperature of the vapor deposition chamber to 800°C, and then feed propane to maintain the pressure of the vapor deposition chamber at 600Pa, a graphene film is prepared by chemical vapor deposition on the anode substrate; after the reaction is completed, a graphene film with a thickness of 8nm is obtained;

[0081] The graphene film is transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com