Electro-spinning device for auxiliary inducing of batch manufacturing of diameter-controllable nano-fibers

A nanofiber and batch technology, which is applied in the field of nanofiber diameter-controlled assisted induction batch electrospinning device, can solve the problems of liquid droplets, uneven diameter of nanofibers, and low output, and achieve the effect of preventing the liquid level from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the structure and function of the present invention in conjunction with the accompanying drawings.

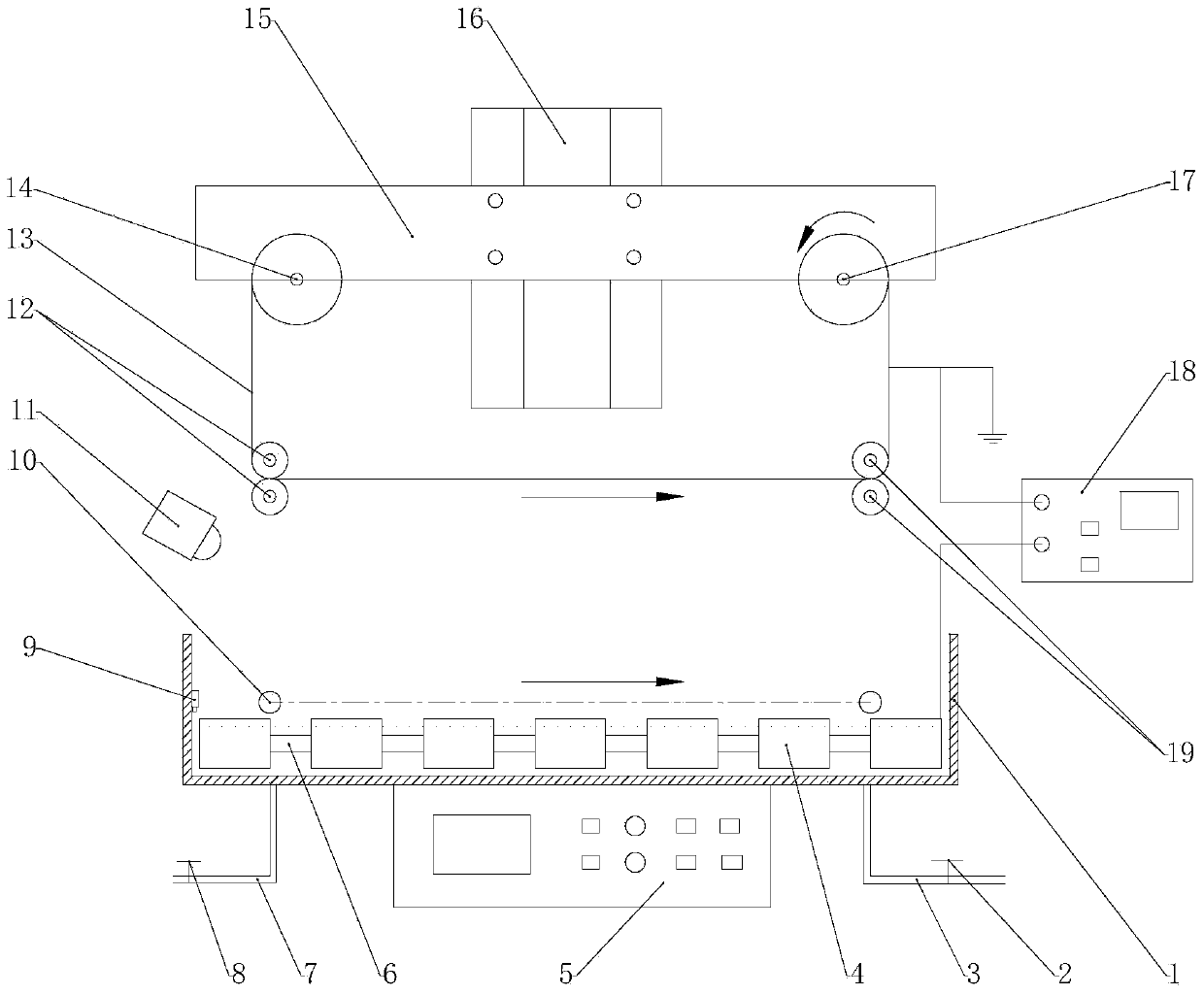

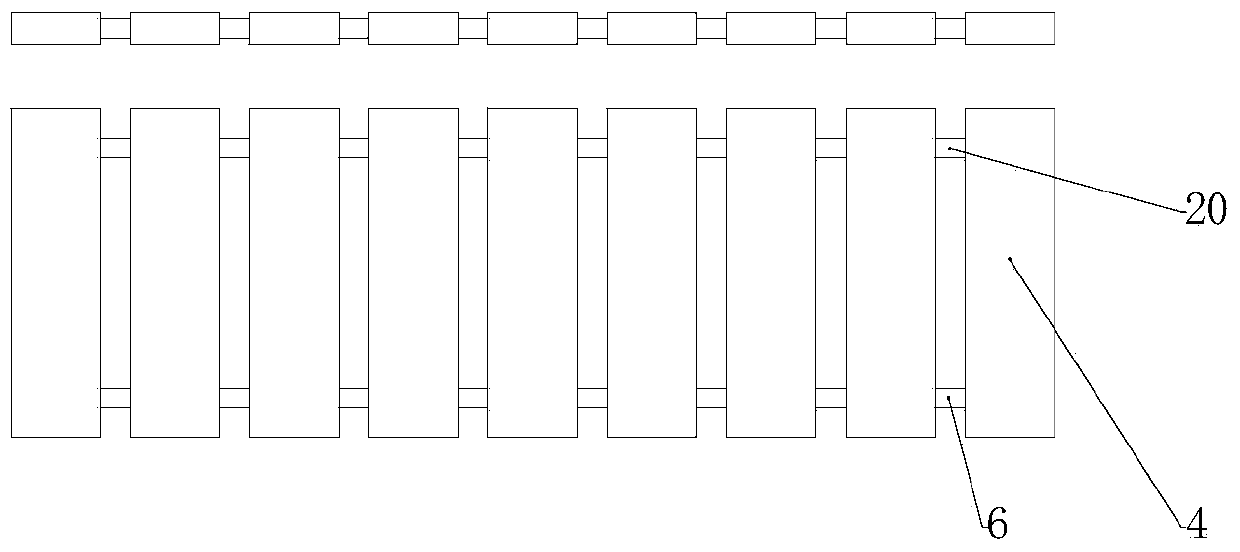

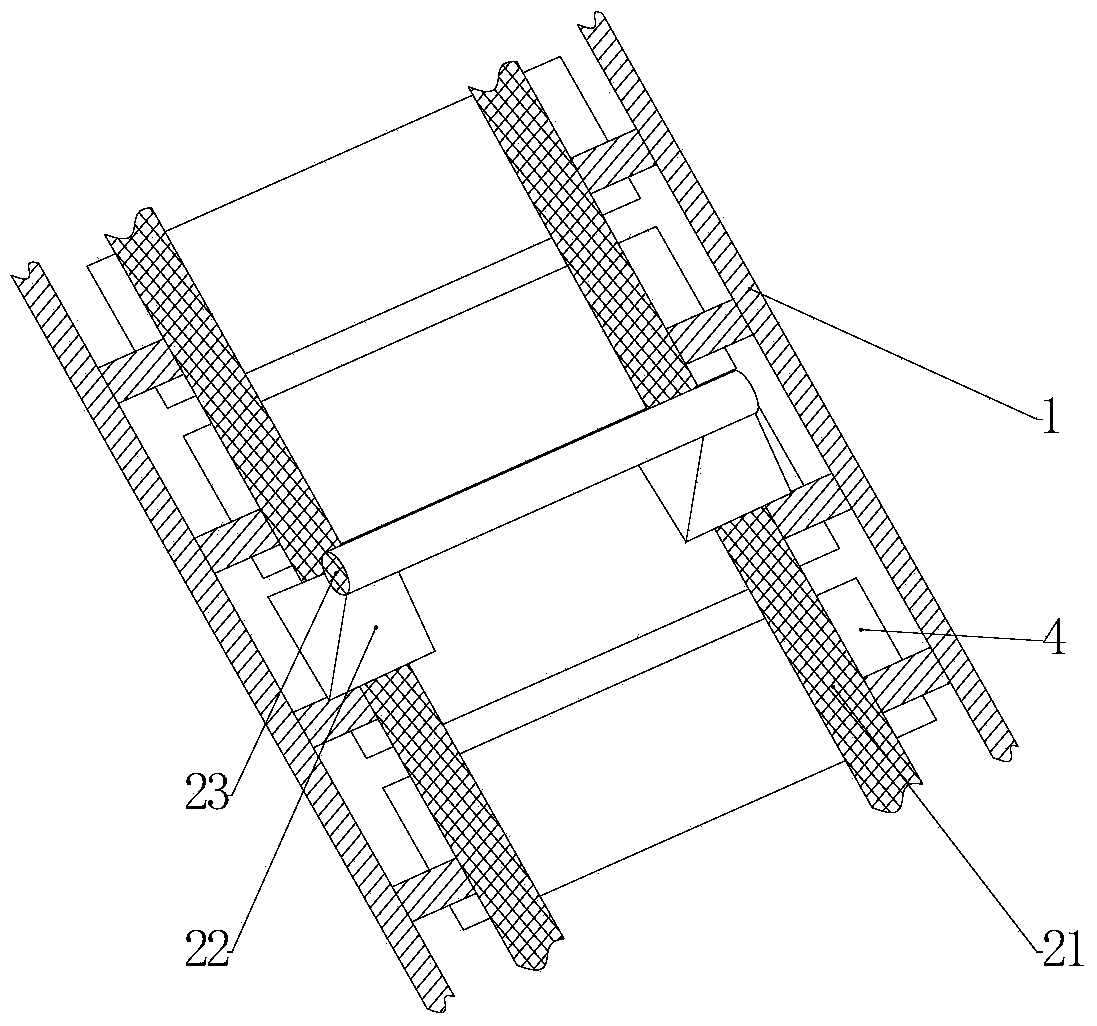

[0027] see Figure 1~5, the embodiment of the present invention is provided with solution tank 1, liquid outlet valve 2, liquid outlet pipe 3, fiber diameter control device, ultrasonic exciter 5, liquid inlet pipe 7, liquid inlet valve 8, ultrasonic liquid level sensor 9, auxiliary induction Device 10, industrial CCD high-definition image sensor 11, collection device, DC high voltage power supply 18. The fiber diameter control device is provided with an adjustment slider 4, a precision screw 6, and a polished rod guide rod 20; the auxiliary induction device 10 is provided with a linear guide rail 21, a slider 22, a slider connecting rod 23, and an installation base 24; Describe collection device feeding auxiliary rolling wheel 12, collecting plate 13, feeding roller 14, collecting device hanging plate 15, servo motor 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com