Antifriction slurry for rectangular jacking pipe with large section, preparation method of antifriction slurry and grouting construction method

A technology of anti-friction mud and construction method, which is applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., and can solve the problem that anti-friction mud cannot adapt to large-section rectangular pipe jacking construction, sandy soil construction, and manual grouting Low efficiency and other problems, to achieve the effect of eliminating uncertain factors, ensuring construction safety and improving friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

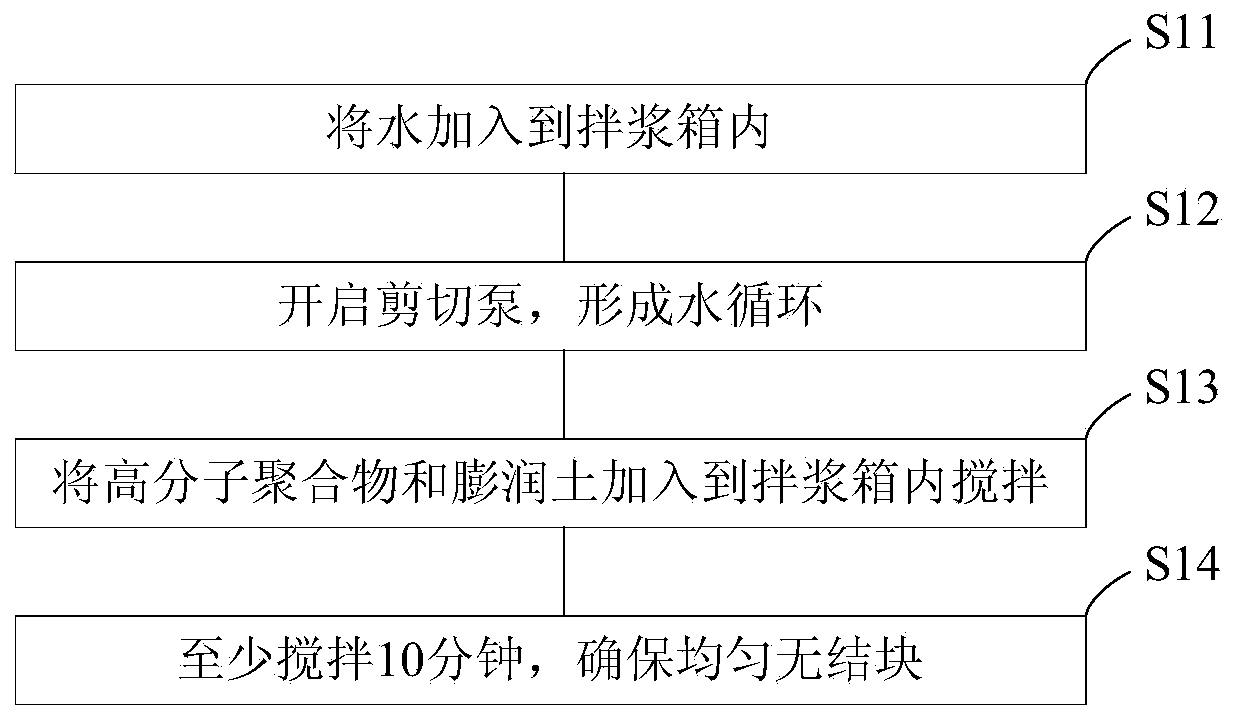

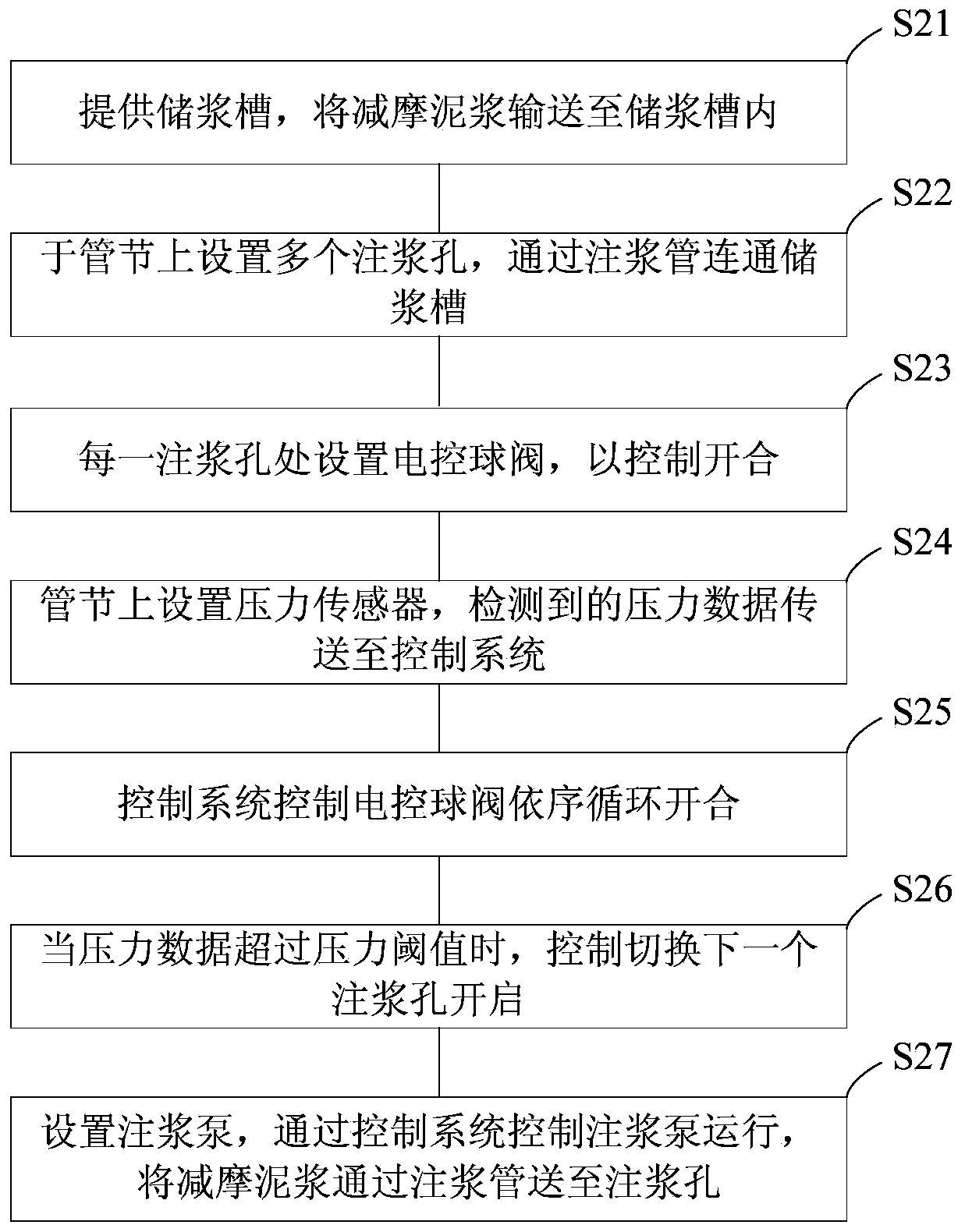

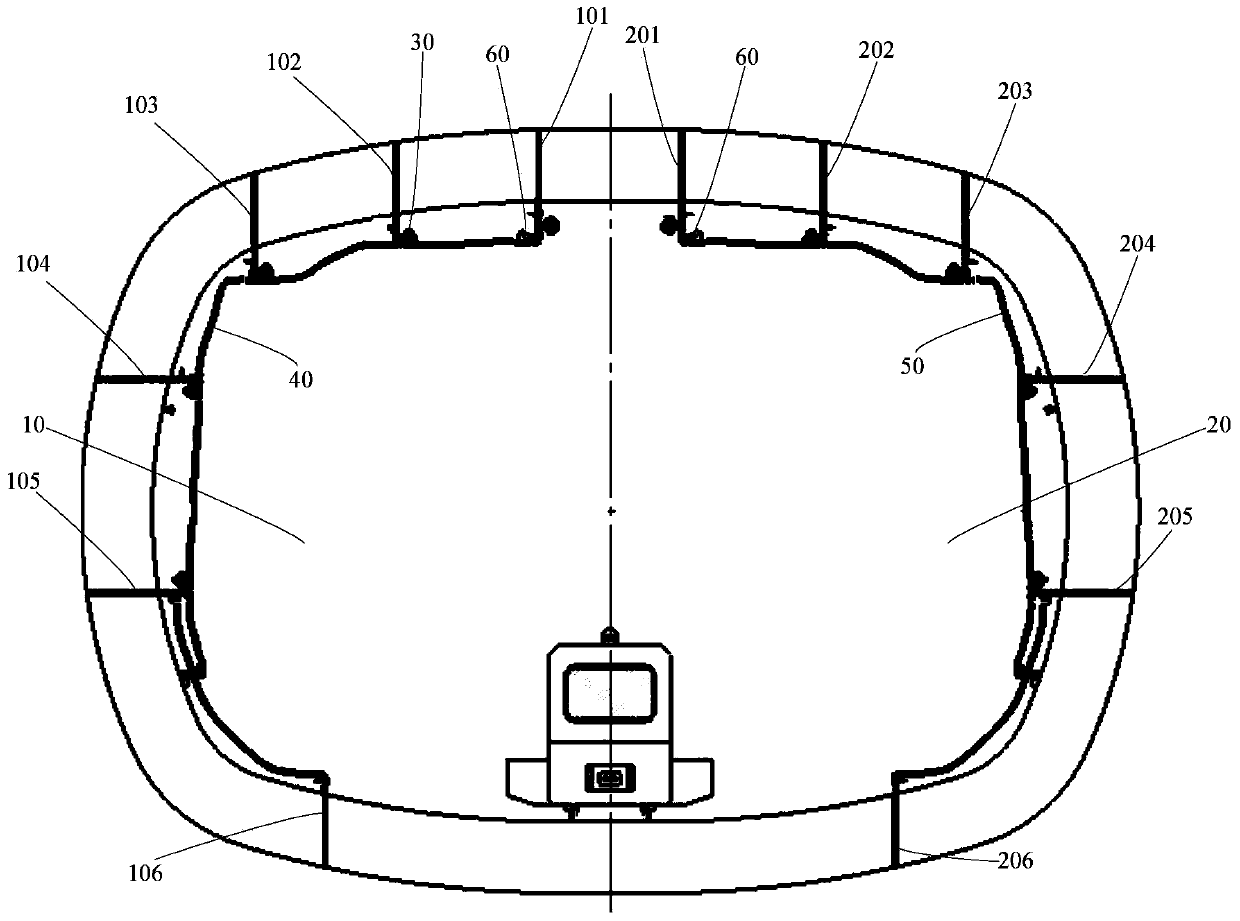

[0035] refer to figure 1 , shows the flowchart of the preparation method of the anti-friction mud for large-section rectangular pipe jacking of the present invention. refer to figure 2 , shows the flow chart of the grouting construction method of the anti-friction mud for large-section rectangular pipe jacking of the present invention. The preparation method and grouting construction method of the anti-friction mud for large-section rectangular pipe jacking of the present invention adopt high-molecular polymer HS-1, bentonite and water to mix in a certain proportion to form the anti-friction mud, which has the characteristics of high viscosity and low specific gravity. The performance index of the anti-friction mud is higher than that of previous mud materials, and it can form a mud sleeve in the construction of large-section pipe jacking, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com