Automated assembly line of horizontal type hydraulic oil cylinder

A hydraulic cylinder and assembly line technology, which is applied in the field of semi-automated assembly line operation process, can solve the problems of backward assembly technology, low efficiency, and easily damaged seals, etc., and achieve the effects of reducing labor intensity, increasing yield, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

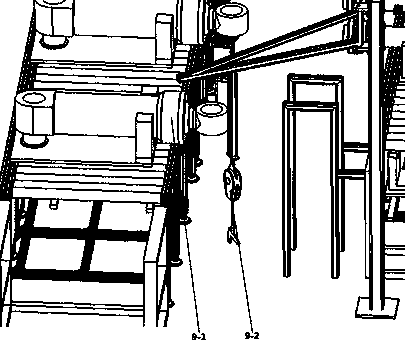

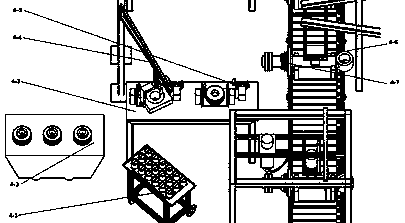

[0016] exist figure 1 In the process, after the piston rod is cleaned by the cleaning station (1), it is hoisted by the cantilever to the piston rod material rack, and then hoisted by the cantilever to the pallet of the piston rod feeding station (2), and the pallet moves forward to the guide sleeve installation station (3). The cleaned guide sleeve is installed with seals at the guide sleeve installation station (3), and is installed on the piston rod with the assistance of the power-assisted manipulator, and the pallet continues to advance to the piston installation station (4). The cleaned piston is installed with a seal at the piston installation station (4), and installed on the piston rod with the assistance of the power-assisted manipulator, and then the pallet is moved forward to the piston tightening station (5), and the anti-loosening cotter pin hole is punched , Clean the drilling iron filings with the air pipe, and install the cotter pin with the air wrench. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com