Light-splitting device and method

A spectroscopic device and beam technology, applied in laser welding equipment, circuits, manufacturing tools, etc., can solve the problems of thermal damage to the cutting track, energy residual cutting track, etc., so as to reduce thermal damage, speed up scribing efficiency, and reduce scratches. The effect of slice line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

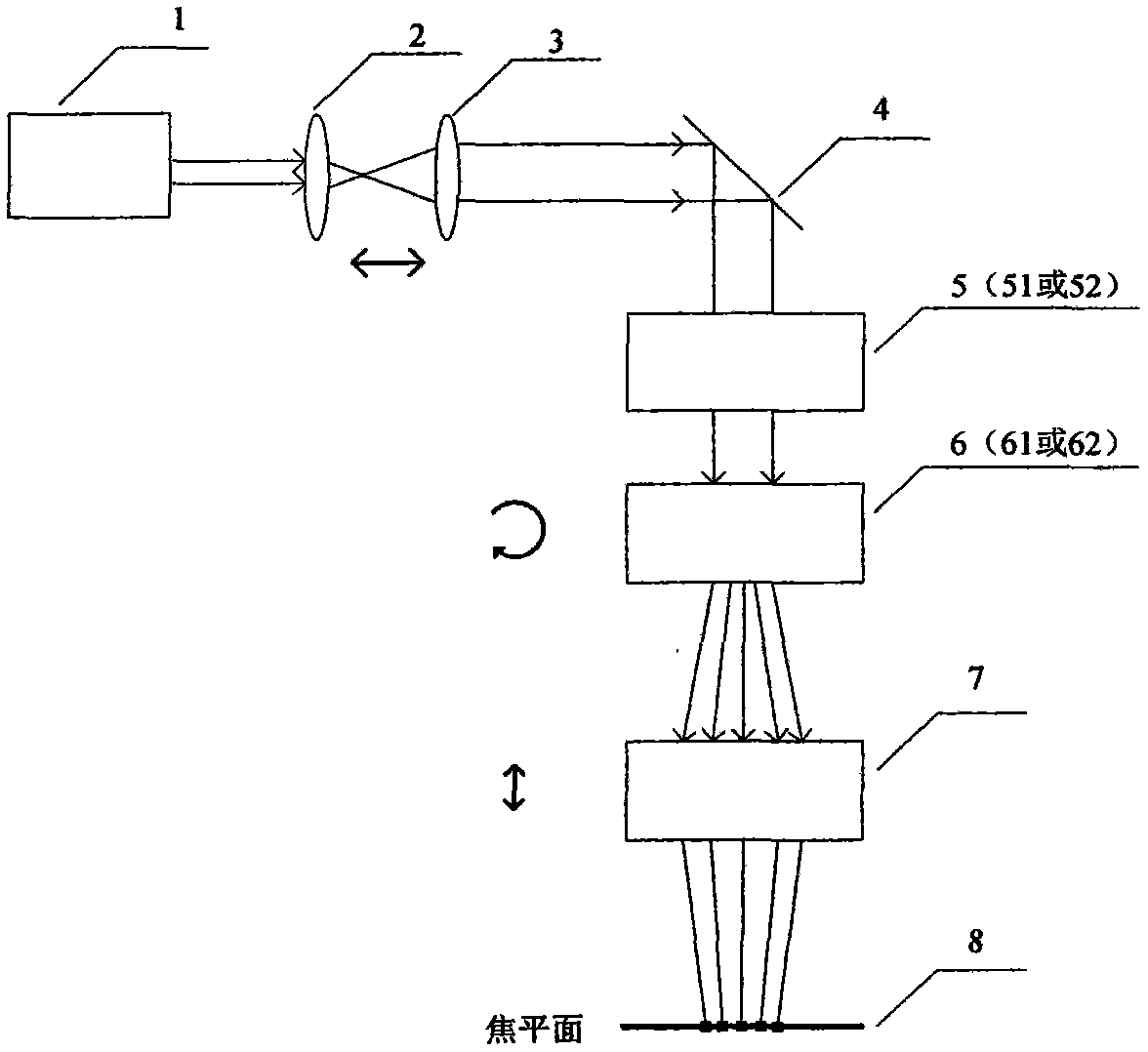

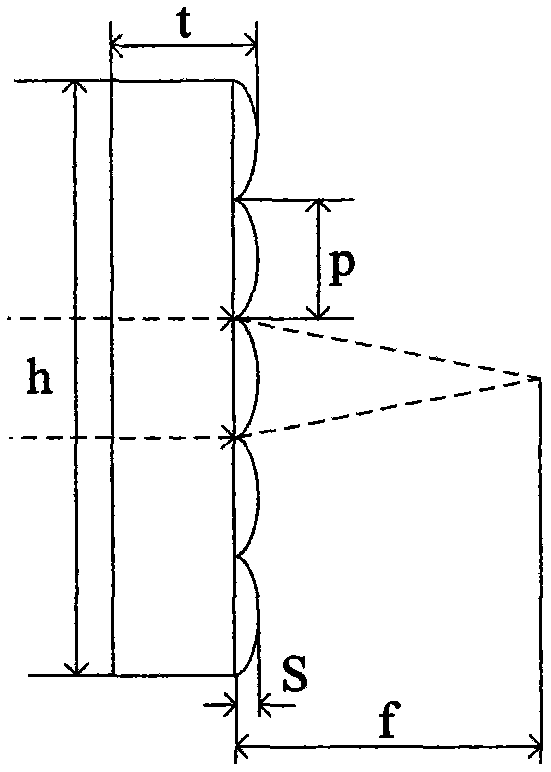

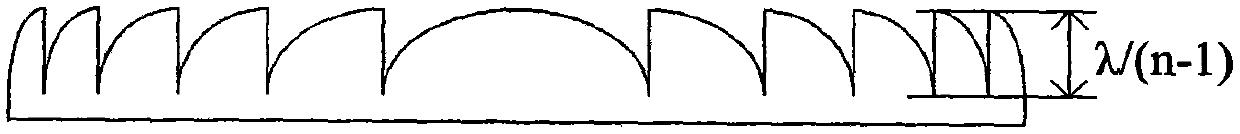

[0038] Such as figure 1 As shown, the Gaussian beam output by the laser 1 is incident on a plane reflector or polarizer 4 after passing through a pair of lenses 2 and 3. Behind the plane reflector or polarizer 4 is a Gaussian beam shaping element 5, followed by a beam splitting element 6, and the laser After passing through the beam splitting element 6, it is incident on the focusing lens 7 and focused on the focal plane.

[0039] Laser 1 is selected according to the material characteristics and processing requirements of the workpiece to be processed. Generally, short-pulse lasers are used, and the common ones are nanosecond or picosecond lasers of 1064nm, 532nm, 355nm and 266nm. The relative distance between the lens 2 and the lens 3 can be adjusted to adjust and optimize the spot size and divergence angle characteristics of the laser output beam. The plane reflector 4 ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com