Intelligentized goose feather ironing device

A goose feather ironing and goose feather technology, which is applied in the direction of sports accessories, sorting, and optical testing for flaws/defects, can solve problems such as damage and affecting the quality of goose feather shuttlecocks, and achieve a reasonable, compact and simple structure for the measurement and control system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

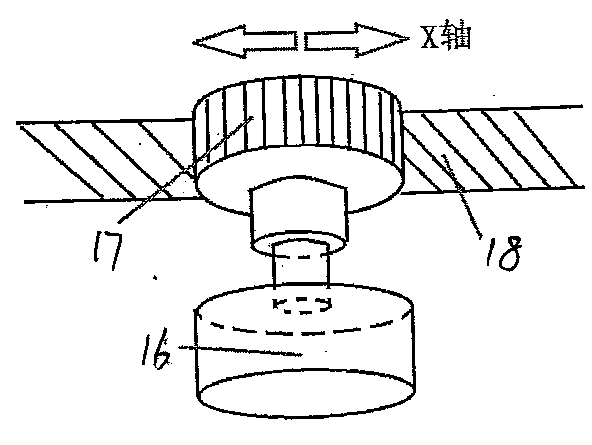

[0031] A fully automatic integrated system for sorting and ironing goose feathers, comprising a base 1, on which an ironing board 2 is arranged, a conveyor belt 4 for transporting goose feathers 3 is arranged above the ironing board, and a goose feather rod clamping device is arranged above the conveyor belt, After the goose feather rod clamping device, a pressing and flattening device for ironing and finishing goose feathers is installed; a color CCD camera A 5 for sorting goose feathers is installed on the front and upper side of the goose feather rod clamping device, and a color CCD camera A 5 is installed on the side of the conveyor belt for ironing. Color CCD camera B 6 for quality inspection of processed goose feathers, camera A, camera B are connected to FPGA 7, FPGA is connected to single-chip microcomputer 8; behind the goose feather rod clamping device, set up a blowing system to blow away unqualified goose feathers 9;

[0032]A field programmable gate array (FPGA) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com