Boil-resisting alums-free sweet potato vermicelli and making method thereof

A technology for sweet potato vermicelli and sweet potato starch, which is applied in the food field, can solve the problems of low content of red glutinous rice starch and inferior sensory quality of vermicelli, and achieves the effects of fine taste, good viscoelasticity and reduced addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

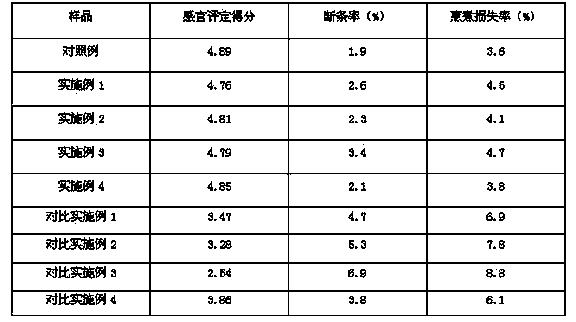

Examples

Embodiment 1

[0048] (1) Preparation of sweet potato starch

[0049] Wash and pulverize sweet potatoes, pass through a 100-mesh sieve first, and then pass through a 200-mesh sieve to obtain coarse sweet potato starch milk. The obtained coarse sweet potato starch milk is sent to a DPF445 disc separator to remove yellow powder to obtain sweet potato starch milk. The obtained sweet potato starch milk is dried That is, sweet potato starch, set aside.

[0050] (2) Preparation of pea starch

[0051] After cleaning the peas, soak them in the water medium for 36 hours, remove the soaked peas, drain the water, grind them, separate them through a 100-mesh sieve to remove the coarse residue, and pass the pea slurry after removing the coarse residue through a 200-mesh The pea starch slurry is obtained by sieving, and the obtained pea starch slurry is dried to obtain the pea starch for subsequent use.

[0052] (3) Preparation of Physalis

[0053] Take a certain amount of peas, and follow step (2) to ...

Embodiment 2

[0068] (1) Preparation of sweet potato starch

[0069] Wash and crush the sweet potatoes, pass through a 120-mesh sieve first, and then pass through a 300-mesh sieve to obtain coarse sweet potato starch milk. The obtained coarse sweet potato starch milk is sent to a DPF445 disc separator to remove yellow powder to obtain sweet potato starch milk. The obtained sweet potato starch milk is dried. That is, sweet potato starch, set aside.

[0070] (2) Preparation of pea starch

[0071] After cleaning the peas, soak them in the water medium for 70 hours, remove the soaked peas, drain the water, grind them, separate them through a 120-mesh sieve to remove the coarse residue, and pass the pea slurry after removing the coarse residue through a 300-mesh The pea starch slurry is obtained by sieving, and the obtained pea starch slurry is dried to obtain the pea starch for subsequent use.

[0072] (3) Preparation of Physalis

[0073] Take a certain amount of peas, and follow step (2) to...

Embodiment 3

[0088] (1) Preparation of sweet potato starch

[0089] Wash and pulverize sweet potatoes, pass through a 100-mesh sieve first, and then pass through a 200-mesh sieve to obtain coarse sweet potato starch milk. The obtained coarse sweet potato starch milk is sent to a DPF445 disc separator to remove yellow powder to obtain sweet potato starch milk. The obtained sweet potato starch milk is dried That is, sweet potato starch, set aside.

[0090] (2) Preparation of pea starch

[0091] After cleaning the peas, soak them in the water medium for 48 hours, remove the soaked peas, drain the water, grind them, separate them through a 100-mesh sieve to remove the coarse residue, and pass the pea slurry after removing the coarse residue through a 200-mesh The pea starch slurry is obtained by sieving, and the obtained pea starch slurry is dried to obtain the pea starch for subsequent use.

[0092] (3) Preparation of Physalis

[0093] Take a certain amount of peas, and follow step (2) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com