Alum-free sheet jelly and production method thereof

A technology of powder skin and malt powder, applied in the field of alum-free powder skin and its preparation, can solve the problems of memory decline, harmful to human health, affecting fetal brain development, etc., and achieves the effects of good viscoelasticity and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A. Paste: Take 800g of sweet potato starch with a particle size of 50-55μm, 70g of potato starch with a particle size of 45-48μm, and 60g of mung bean starch with a particle size of 50-55μm and mix them evenly to obtain a mixed starch. 10g of water and 10g of malt powder with 3 times the weight of starch, stir evenly, then add 15g of table salt, 0.15g of polyglycerol fatty acid ester, 0.14g of fenugreek gum, 0.15g of linseed gum and 0.12g of sodium carboxymethylcellulose, and stir evenly ;

[0021] B. Molding: Heat the mixture obtained in step A at 55°C for 6 minutes, then at 66°C for 2 minutes to obtain a vermicelli slurry, and then place it in a vermicelli molding machine to form it to obtain alum-free vermicelli.

Embodiment 2

[0023] A. Paste: Take 1000g of sweet potato starch with a particle size of 50-55μm, 70g of potato starch with a particle size of 45-48μm, and 90g of mung bean starch with a particle size of 50-55μm and mix them evenly to obtain a mixed starch. Water with 4 times the weight of starch and 12g of malt powder, stir evenly, then add 15g of salt, 0.1g of modified soybean lecithin, 0.17g of fenugreek gum, 0.18g of linseed gum and 0.14g of sodium carboxymethylcellulose, and stir evenly;

[0024] B. Molding: Heat the mixture obtained in step A at 58°C for 8 minutes, then at 62°C for 3 minutes to obtain a vermicelli slurry, and then place it in a vermicelli molding machine to form it to obtain alum-free vermicelli.

Embodiment 3

[0026] A. Paste: Take 900g of sweet potato starch with a particle size of 50-55μm, 85g of potato starch with a particle size of 45-48μm, and 75g of mung bean starch with a particle size of 50-55μm to obtain a mixed starch, and add the mixed starch to the mixed starch. 3.5 times the starch mass of water and 11g of malt powder, stir evenly, then add 14g of salt, 0.06g of polyglycerin fatty acid ester, 0.06g of modified soybean lecithin, 0.15g of fenugreek gum, 0.16g of linseed gum and carboxymethyl fiber Vegetarian sodium 0.13g, stir well;

[0027] B. Molding: Heat the mixture obtained in step A at 57°C for 7 minutes, then at 64°C for 2 minutes to obtain a vermicelli slurry, and then place it in a vermicelli molding machine to form it to obtain alum-free vermicelli.

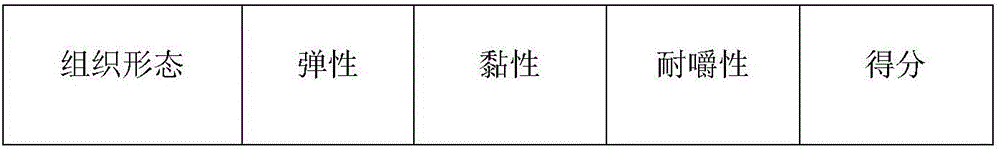

[0028] Fenpi sensory evaluation

[0029] Select 10 persons who have more than 3 years of gourmet food tasting experience, and evaluate the powder prepared in Examples 1-3 in aspects of structure, elasticity, visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com