A kind of oxygen-increasing kneading method

A technology of kneading machine and oxygen generator, which is applied in the field of oxygen-increasing kneading in black tea processing, to achieve the effect of improving freshness, mellow taste and sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An oxygen-increasing rolling method suitable for tea processing, especially for black tea shaping operations, provided by the following steps:

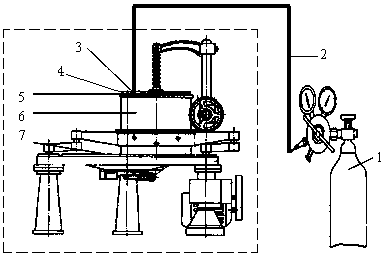

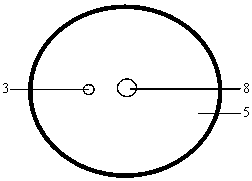

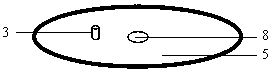

[0017] 1. Design figure 1 The device: the device is mainly composed of oxygen generator (oxygen tank) 1, plastic connecting pipe 2, connecting head 3, stainless steel pipe 4, kneading cover 5, kneading barrel 6, kneading plate 7, etc., plastic connecting pipe 2 One end is connected to the oxygen generator (oxygen tank) 1, and the other end is connected to the connector 3. The connector 3 is located on the kneading cover 5 and directly embedded on the kneading cover 5 (see figure 2 , image 3 ), the other end of the connector 3 is connected to the stainless steel pipe 4, the other end of the stainless steel pipe 4 is closed, and the stainless steel pipe 4 is fixed on the back of the kneading cover 5 by glass glue (see Figure 4 ), several small holes with a diameter of 1mm are set on the pipe wall of the stainless steel pipe ...

Embodiment 2

[0020] Referring to Example 1 ( Figure 1-Figure 4 ), first insert the connector 3 on the kneading cover 5 of the traditional 55-type kneading machine, set the stainless steel pipe 4 on the back of the kneading cover 5 through glass glue, the stainless steel pipe 4 is closely connected with the connector 3, and the stainless steel pipe 4 is provided with small holes (not shown in the figure), the other end of the connector 3 is connected to the plastic pipe 2, and the plastic pipe 2 is connected to the oxygen generator (oxygen cylinder) 1. During operation, put the finished product into the kneading barrel 6 according to the traditional kneading process, rotate the kneading machine handle to cover the kneading cover 5, then turn on the switch of the oxygen generator 1, control the air valve so that the oxygen flux is about 0.1MPa, and then Start the kneading device, the oxygen is input into the stainless steel pipe 4 through the plastic connecting pipe 2, and then output throu...

Embodiment 3

[0022] Referring to Example 1 ( Figure 1-Figure 4 ), first put the connector 3 on the kneading cover 5 of the traditional 35-type kneading machine, set the stainless steel pipe 4 on the back of the kneading cover 5 through glass glue, the stainless steel pipe 4 is closely connected with the connector 3, and the stainless steel pipe 4 is provided with hole (not shown in the figure); the other end of the connector 3 is connected to the plastic pipe 2, and the plastic pipe 2 is connected to the oxygen generator 1 (oxygen cylinder). During operation, put the finished product into the kneading barrel 6 according to the traditional kneading process, rotate the kneading machine handle to cover the kneading cover 5, then turn on the switch of the oxygen generator 1, and control the air valve so that the oxygen flux is about 0.07MPa. Then start the kneading device, oxygen is input into the stainless steel pipeline 4 through the plastic connecting pipeline 2, and then output through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com