The heating device in the purification room behind the firewall in the biomass gasification station

A clean room and firewall technology, applied in the field of heating, can solve problems such as heating failure, equipment freezing and cracking, and achieve the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

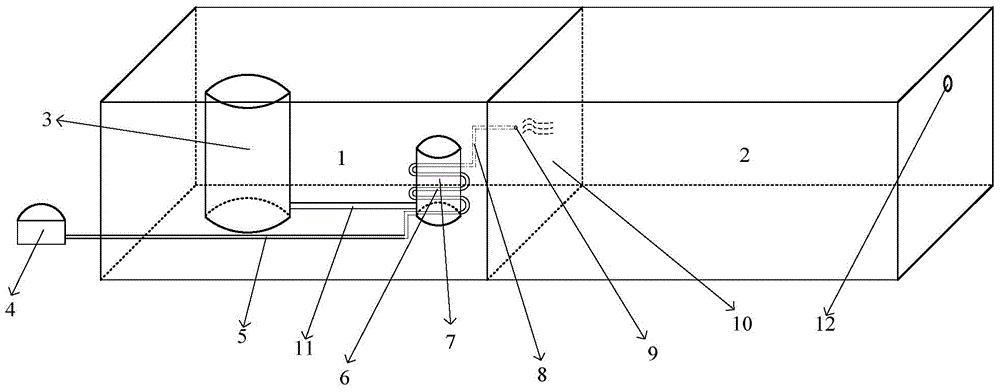

[0011] Such as figure 1 As shown, the biomass gasification station of this embodiment includes a gasification room 1 and a purification room 2, a firewall 10 is added between the gasification room 1 and the purification room 2, and a gasification furnace is installed in the gasification room 1 3 and the dry dust collector 7, the gasification furnace 3 and the dry dust collector 7 are connected through the first pipeline 11, and the coil pipe 6 is wound on the dry dust collector 7 in the gasification room 1, One end of the coil pipe 6 communicates with the axial flow fan 4 placed outdoors through the second pipe 5, the other end of the coil pipe 6 communicates with one end of the heat preservation pipe 8, and the other end of the heat preservation pipe 8 passes through the firewall 10 The air outlet 9 on the top is placed in the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com