Tool for quick disassembly and assembly of blast furnace blowpipe and tight beating of tapered wedges and use method thereof

A blast furnace and tool technology, which is applied in the field of quick disassembly and assembly of blast furnace blowpipe tightening wedge tools, can solve the problems of heavy blowpipe 3, long wind break time, and great potential safety hazards, so as to reduce the risk of safety injury and reduce investment in operations. Personnel, the effect of reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

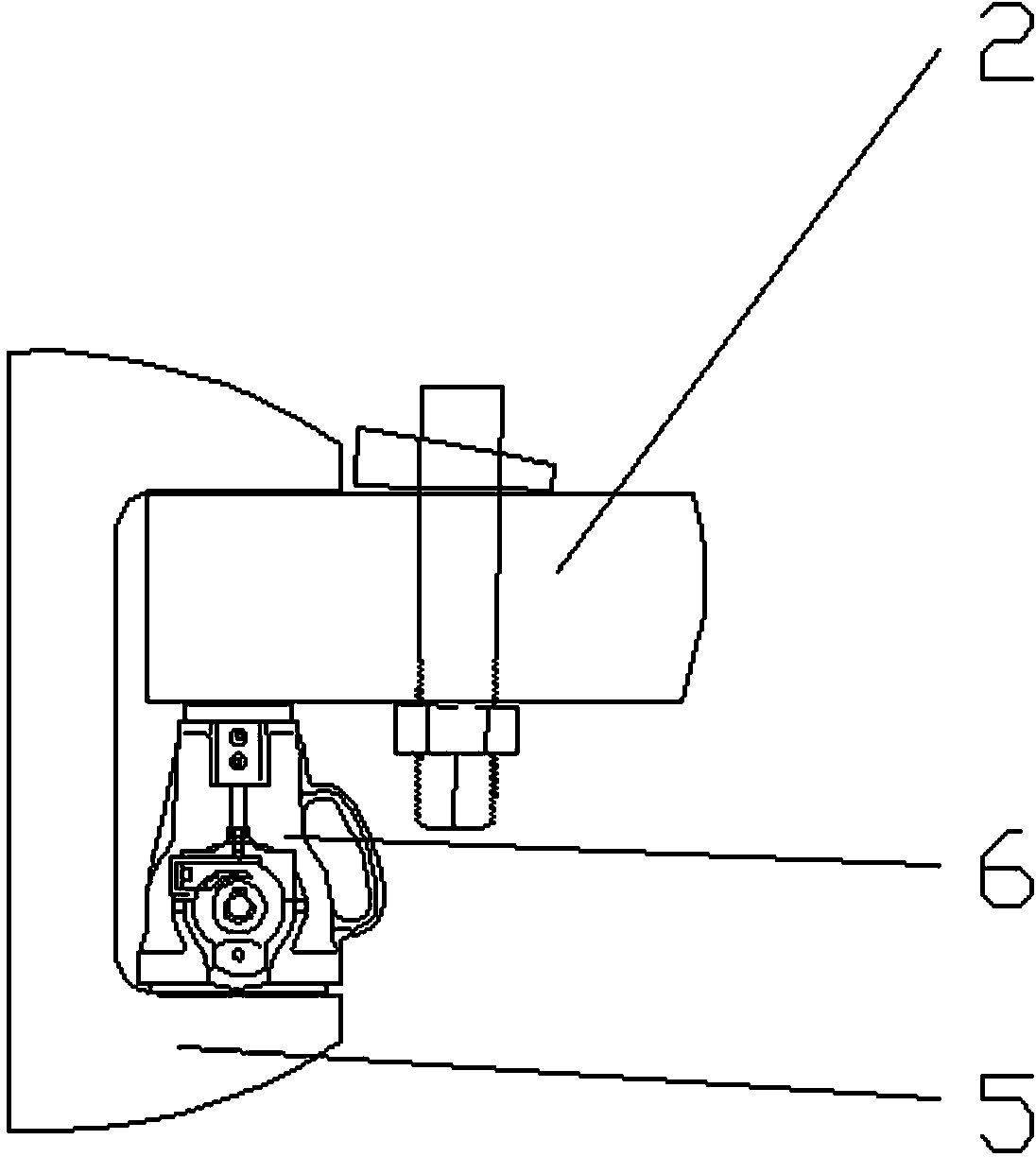

[0016] See figure 2 , A quick disassembly and assembly of blast furnace blowpipe tightening diagonal wedge tool, including a tool body made of a steel plate with a thickness of 30mm, which is integrally cut according to the size. The upper and lower ends of the tool body are integrated and connected with two clamps in the same direction. Code 5, a jack 6 is mounted on the bottom card code 5, and the jack 6 can clamp the connecting flange 2 between the card code 5 and the jack 6 when the blowpipe 3 is connected with the corrugated compensator 1 and the flange 2.

[0017] See image 3 , The application process of the above-mentioned quick disassembly and assembly blast furnace blowpipe tightening diagonal wedge tool is:

[0018] When disassembling the blowpipe 3, first use a 2T hand chain hoist to tighten the blowpipe 3 by using the pre-welded support on the blast furnace s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com