Labeling Machine

A labeling machine and labeling technology, which is applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of inconvenient installation and transportation, large space occupation, large volume of labeling machine, etc., and achieves easy installation and use, and simple structure , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

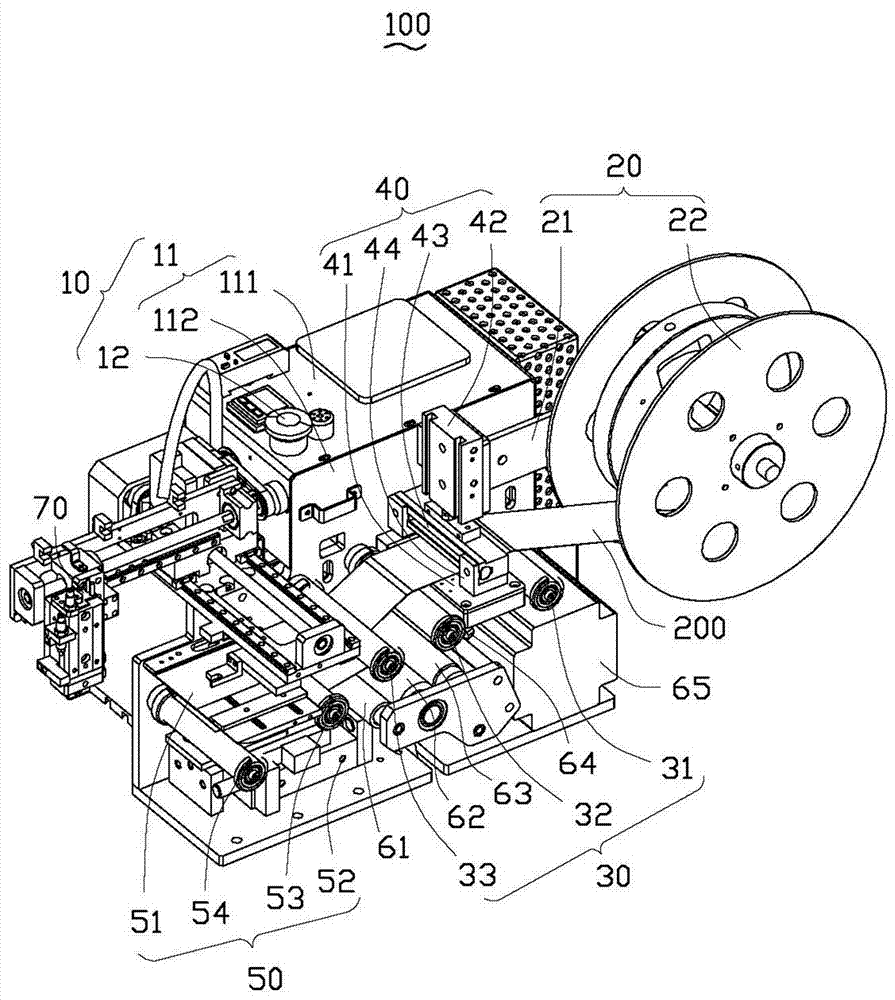

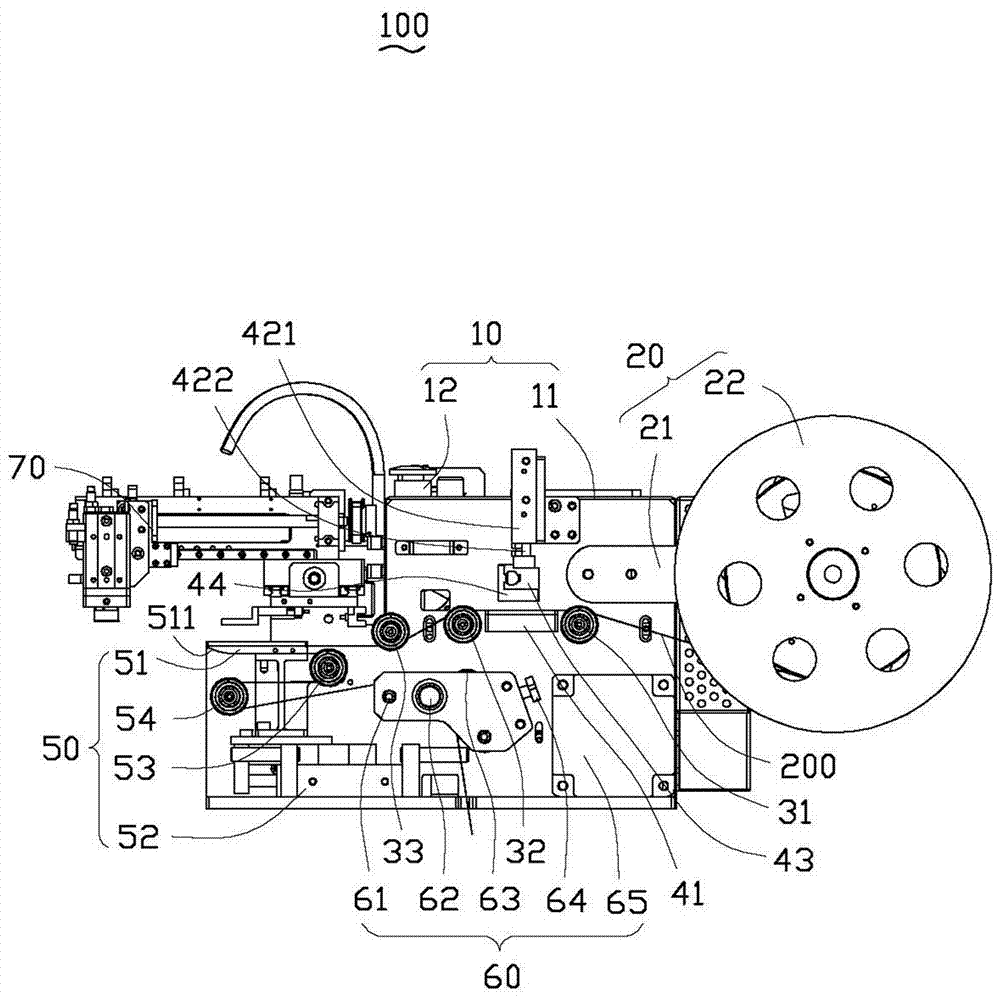

[0043] see figure 1 and figure 2 , the labeling machine 100 of the present invention is used for the labeling process in the product assembly process. The labeling machine 100 includes an operating unit 10 , a feeding assembly 20 , a transmission assembly 30 , a pressing assembly 40 , a stripping assembly 50 , a receiving assembly 60 and a manipulator 70 . The feeding assembly 20 is covered with a material belt 200 , the transmission assembly 30 drives the material belt 200 through the pressing assembly 40 and the stripping assembly 50 to the receiving assembly 60 , the transmission assembly 30 is arranged on the feeding assembly 20 On one side, the pressing assembly 40 presses and releases part of the material belt 200 on the transmission assembly 30 , and the stripping assembly 50 is located on one side of the transmission assembly 30 .

[0044] The operation unit 10 includes a storage box 11 and buttons 12 . The accommodating box 11 includes a top wall 111 and a side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com