Conveying belt type woodworking thickness planer

A conveyor belt, woodworking technology, applied in the direction of the planer, etc., can solve the problem of sacrificing processing efficiency, and achieve the effect of flexible processing control, convenient joint use, and fast feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

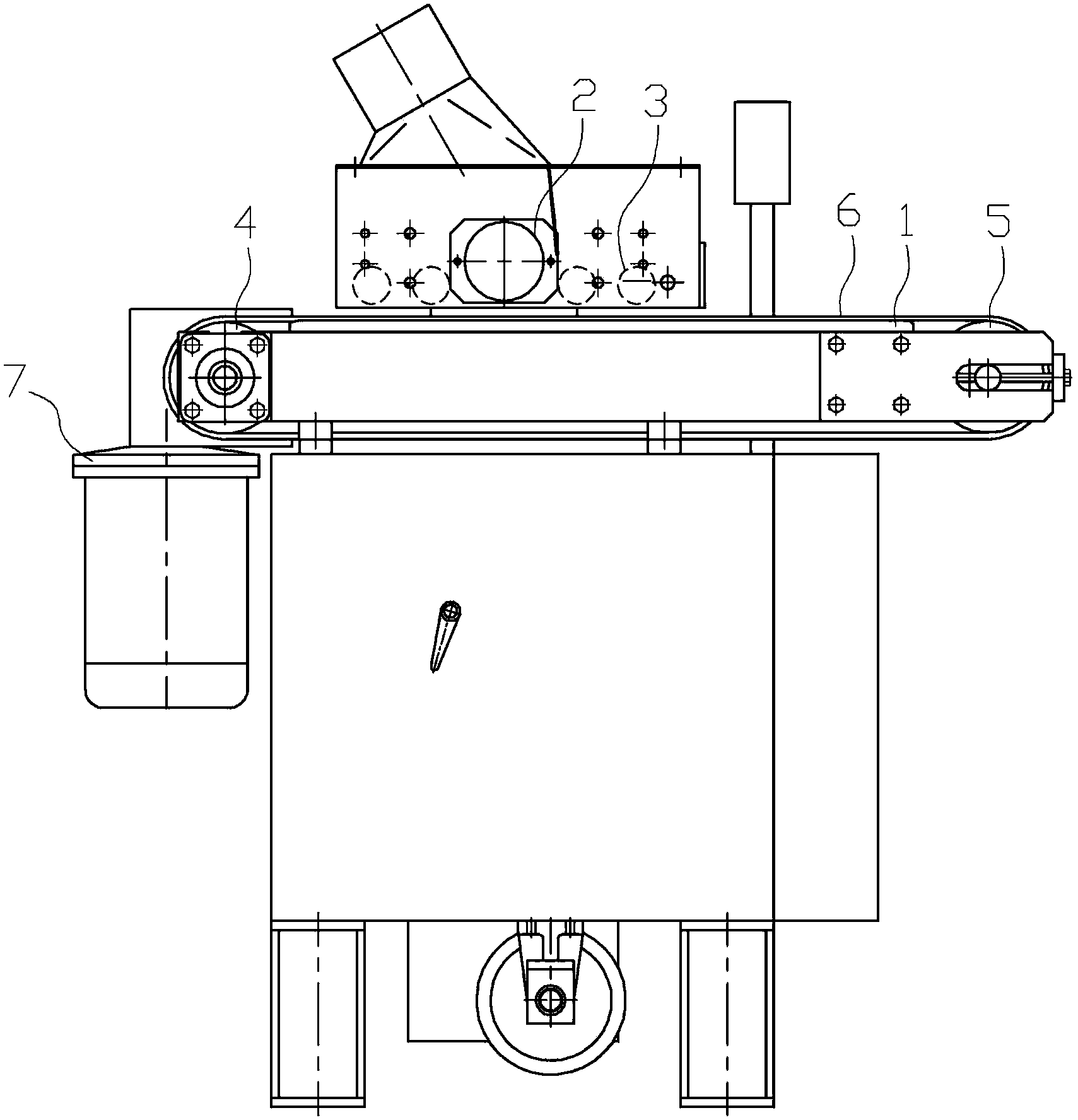

[0007] Such as figure 1 As shown, it includes a worktable 1, a cutting mechanism 2 and a pressing device 3 are arranged on the top of the worktable 1, and a belt conveyer is provided on the workbench 1, and the belt conveyer includes a driving roller 4, from The driving roller 5, the conveyor belt 6 and the driving mechanism 7, the driving roller 4 and the driven roller 5 are respectively fixed laterally on both ends of the worktable 1, and the conveyor belt 6 is set on the periphery of the driving roller 4, the driven roller 5 and the worktable 1, And the inner bottom surface of the conveyor belt 6 is in close contact with the upper surface of the worktable 1 , and the driving roller 4 is connected with the driving mechanism 7 . The driving mechanism 7 includes a motor, a reducer and a stepless speed regulation mechanism, which can be driven by a frequency converter to realize stepless speed regulation.

[0008] A tensioning device is provided at the end of the driven roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com