Method for producing a machine element, and machine element for an electric machine

A technology of machine components, powder particles, used in the field of machine components of magnetic fields, and the field of manufacturing such machine components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

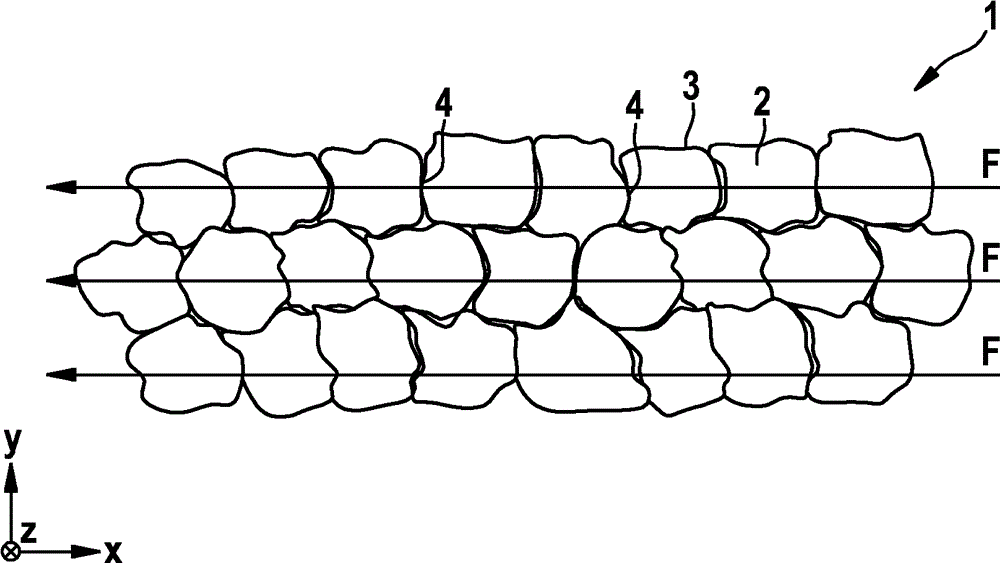

[0033] figure 1 A schematic cross-sectional view of a section of a machine element 1 made of SMC material is shown. The SMC material basically consists of powder particles 2 of the same size, the powder particles are made of magnetic material such as iron, the surfaces of the powder particles are insulated by an insulating layer 3 . The powder particles 2 have a diameter of about 0.1 mm and are roughly cuboidal or spherical in shape with irregularly shaped surfaces.

[0034] The particles 2 are pressed against each other during the pressing process in order to define the shape of the machine element 1 to be produced and subsequently hardened in a thermal process so that the powder particles are permanently connected to each other. figure 1 An exemplary arrangement of powder particles 2 after a thermal process is shown. One sees powder particles 2 of the same size, which lie against each other so that the area of the interstices between the particles 2 is minimized as much ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com